| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Automatic Wire Shelf Welding Machine |

|---|---|

| Brand Name: | HWASHI |

| Model Number: | WL-TSP-100/150K |

| Certification: | CE/CCC/ISO |

| Place of Origin: | China |

| MOQ: | 1 set |

| Price: | Negotiation |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 50 sets per month |

| Delivery Time: | 30 working days after received your payment |

| Packaging Details: | Sea worthy wooden package or PVC Film for FCL |

| Product Name: | Hwashi Wire Mesh Welding Machine For Animal Cages Automatic Fast Metal Mesh Spot Welder |

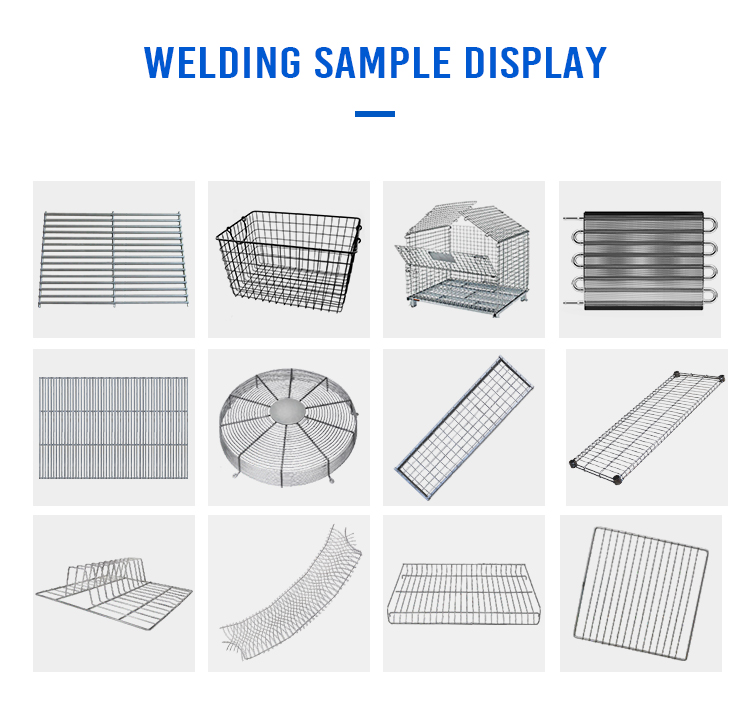

| Application: | Mesh Product |

| Size: | According to your product |

| Weight (KG): | According to your product |

| Condition: | New |

| Warranty: | 1 Year |

| Standard: | CE |

| Welding material: | Iron wire |

| Company Info. |

| Guangdong Hwashi Technology inc. |

| Verified Supplier |

| View Contact Details |

| Product List |

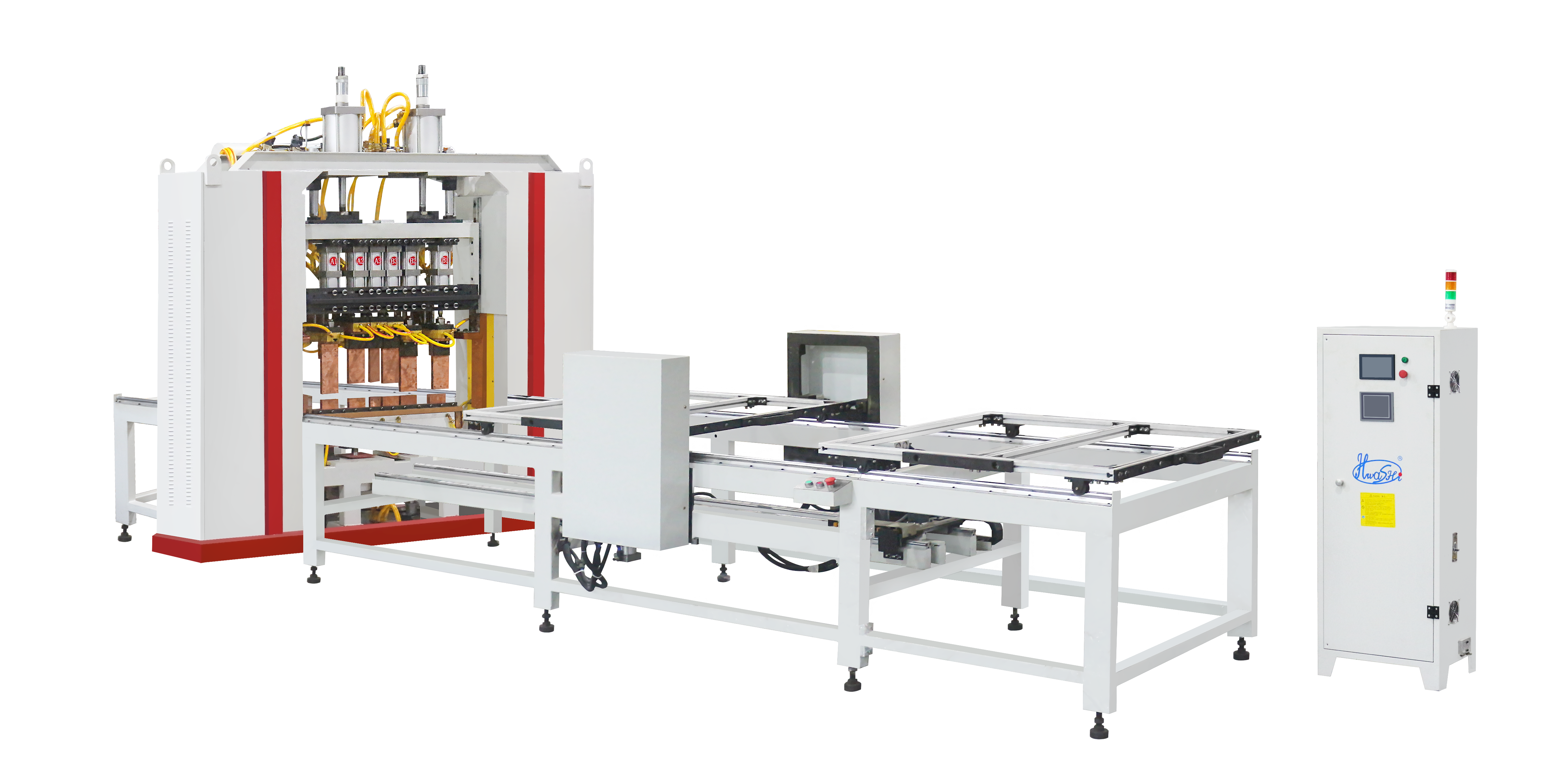

Hwashi Wire Welding Machine For Animal Cages Automatic Fast Metal Mesh Spot Welder

The wire mesh multi-head automatic welding machine introduces a

cutting-edge approach to welding processes. It stands out by

incorporating ten electrodes and a sophisticated automatic feeding

system. The system ensures seamless wire integration, with wires

dropping automatically into the fixture for a fully automated

loading process. Subsequently, the machine autonomously carries out

both feeding and welding operations.

What sets this machine apart is its one-way and double-layer

feeding device, capable of dynamic forward and backward movement to

accomplish welding tasks. The welding distance is customizable,

adding a layer of flexibility to the welding process. This

feature-rich machine is specifically tailored for batch production

scenarios, especially ideal for wire mesh requiring multiple-point

welding.

The welding methodology employed is a unique one-way double-layer

automatic stepping feeding, utilizing 10 welding heads. This

innovative approach results in an effective welding width of 1200mm

and an effective welding length of 1000mm. The machine's

composition includes a robust main machine body, welding

transformer, pneumatic drive device, upper and lower electrodes,

automatic wire filling device, an advanced electrical control

system, cooling system, and a PLC operation control system.

This state-of-the-art wire welding machine not only ensures

efficiency in batch production but also provides unparalleled

adaptability and precision in welding operations, making it a

standout solution in the industry.

Ideal for Various Industries:

Metal Fabrication: Perfect for welding metal components with precision and

efficiency.

Construction:Streamline welding processes for structural components and

frameworks.

Automotive: Achieve high-quality welds for automotive parts with ease.

Custom Projects: Adapt the machine to your specific project needs, from prototyping

to large-scale production.

|  |

Intelligent welding control system Automatic welding by inputting coordinate data of welding position, welding current and other data. | Special product molds welding platform Processing and production according to the size of each mesh product |

|  |

X.Y axis moving device Equipped with automatic movement of the workpiece mold along X and Y axes, only manual swinging and removal of the workpiece is required | Single head long arm type welding The equipment adopts single head long arm type welding structure, can be customized according to the needs of the workpiece double row or multi-row welding head |

Specification

| Model | WL-TSP-100/150K |

| Input Power (V/φ) | 380/3 |

| Rated Power (KVA) | 100/150 |

| Applicable Material | Stainless Steel, Carbon steel, Aluminum, Metal |

| Electrode Force (KG) | 250-400 |

| Wleding Thickness (MM) | 1-5mm |

| Warranty | 1 years |

| Mesh Welding Range | 1000mm X 1000mm |

XY axis automatic moving wire welding machine

The wire welding machine features a highly efficient servo motor-driven XY axis mold frame, utilizing a synchronous belt drive system. Controlled by the advanced control system, the machine enables precise control over the walking step length and speed. Once the manual material is securely fixed onto the mold frame, the switch is activated, and the industrial control computer takes charge. The product then undergoes automated welding as it alternately moves along the X and Y axes of the mold frame, seamlessly completing the welding process for each joint. Upon completion, the machine automatically returns to the origin without requiring additional manual intervention. This eliminates the need for additional personnel during the welding operation. Meanwhile, the operator can utilize the available time to set up the next material, optimizing efficiency and reducing labor costs. By effectively utilizing the welding time for material setup, the machine ensures maximum productivity and streamlines the overall workflow.

|