| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Pure ES Series CNC Press Brake |

|---|---|

| Brand Name: | genuo |

| Model Number: | ES-18T/20T/30T/40T/60T/100T |

| Certification: | M.2019.206.C3862 |

| Place of Origin: | China |

| MOQ: | 1 |

| Payment Terms: | L/C, T/T, D/P, D/A |

| Supply Ability: | 1 Set/Sets Every 15~35 days |

| Delivery Time: | 90 days |

| Packaging Details: | carton box |

| product Name: | Pure Electric Servo CNC Press Brake Machine |

| Application: | Metal Plate Aluminum alloy ironBending |

| CNC Control System: | Genuo ETC-16T CNC control |

| Voltage: | 220V/380V/415V/440V/customized |

| Machine Color: | Customer Choose |

| Main Motor Power: | 11KW/13KW/15KW/30KW |

| Bending Material: | Metal .Stainless Steel Sheet .Aluminum |

| Tools and Clamps: | GENUO GNSP standard fast support |

| After-sales Service Provided: | Online Support Video Technical Support |

| core selling point: | Eco-friendly ,Energy-saving,low noise |

| value-added services: | Presented Two years warranty |

| Degree of automation: | Fully Automatic |

| Bending Length: | 1000mm /1250mm/1600mm/2500mm/3200mm |

| Machine Axes: | High precision Y1,Y2,X,R axis |

| Price: | negotiable |

| Company Info. |

| Maanshan Genuo Machinery Manufacturing Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

Energy-Saving Electric CNC Press Brake Metal Sheet Bending Machine Eco-Friendly

Machine Introduction :

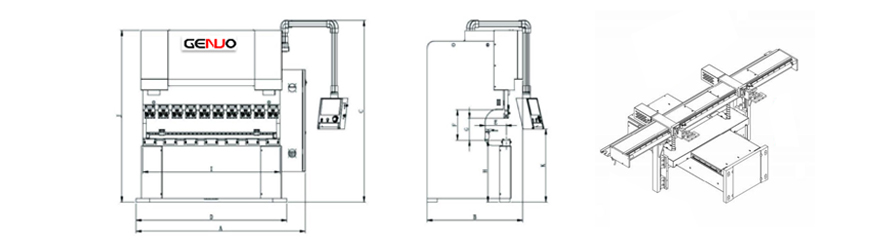

Genuo Pure ES series electric servo CNC press brake with integral machiningand tempering ultra-high strength bed, driven by AC servo motor and ball screw drive mechanism, it maximizes productivity. The machine all uses well-known foreign brand accessories, the whole series is standard with Genuo accessories, such as fast jig and quick change of top punch, to save time. 100% all-electric stamping brakes are highly versatile and designed for bending metal materials for a variety of applications.

In addition, Genuo's self-developed CNC controller maximizes value

creation and reduces costs, and the user-friendly interface

operation makes the Pure ES series extremely cost-effective. High

efficiency, low noise, environmental protection.

The pure electric servo press brake automatically outputs the

appropriate power according to the working conditions, without the

use and replacement of hydraulic oil, avoiding the pollution of the

waste liquid pressure oil to the environment.

Compared with electro-hydraulic press brakes, it can save more than

60% of energy, reduce operating costs, and increase efficiency by

more than 40%, thus becoming a more stable and reliable choice.

→ Product Configuration:

Standard Equipment:

< European-style punch and 4V/2V/1V Dies | Feature: < Delem DA-66T,DA-69T CNC control.

< Lasercheck angle detection.

< 20~100Tons and 1000~3200mm Lenght options. |

→ CNC Controller :

⊙ GENUO ETC-16T CNC Control ETC-16T is a new generation of performance bending control system of GENUO dedicated to synchronous press brakes. The system has rich interfaces, which can be easily connected to the automatic production line as a bending unit. It can cooperate with industrial robots in interactive operation,to the greatest extent freefrom manual intervention, improve the accuracy and efficiency of the equipment. |

|

→ Structure Details :

▼ Heavy-Duty Ball Screw Genuo Pure ES Series Press brake is driven by the well-known brand servo main motor and the German IF heavy duty ball screw transmission mechanism. It ensures the efficiency of the machine, maximizes productivity and achieves high-precision bending operations. |

|

▼ Electrical Components Durable France Schneider electrics ensure the stable operation of the machine. Reasonable line connection and arrangement greatly reduces the failure rate. The integrated control module of hydraulic valve group makes the sliding block move smoothly and accurately. And the operator and all parts of the machine played a good protection. |

|

▼ Servo Driver & Main Motor Compared with other motors, servo motors have significant advantages, such as energy saving, environmental protection and pollution-free, fast slider speed, high production efficiency and low maintenance costs. The servo motor driven bending machine does not use the hydraulic system to transfer pressure, avoiding the negative impact on accuracy and speed, higher bending accuracy, quiet operation of the drive mode, saving costs. It is also more suitable for the processing environment of ambient temperature and high load for a long time. |

|

▼ Linear Guide Rail (back gauge) The linear guide rail guarantees the precision level of the rear stopper. Back gauge system Establishing the right back gauge for your projects will allow for increased part production and precision. From intricate parts which typically require more axes to large quantities that require more time and therefore increased cost. GENUO technicians are happy to assist you with any questions on your project requirements. |

|

→ Tooling and Clamps :

GENUO provides a variety of tooling solutions to meet your different production needs. Not only that, we are also experts in the field of bending tools. If you have any special bend, our engineers will customize special tools for each workpiece, which greatly expands your press brake function and revenue.

To help greatly improve your productivity and business benefits.The Pure ES Series Press Brake comes standard with Genuo accessories such as quick clamps and quick change top punches to save time.

→ PARTS Systems :

| LASER Safety Guards DSP LASER protects the press brake operator from the danger of crushing that can take place accidentally between the moving part of the machine and the fixed one. It assures to carry out the machine working cycle penalizing its execution time in the least. |

| Delem Controller Optional DA-66T offers 2D programming, including automatic bending sequence

calculations and collision detection, 3D visualization in

simulation and production. DA-58T is an advanced complete 2D graphic control solution for

synchronous press brake servo and inverter control. DA-53AT features industrial-grade multi-touch technology, high-resolution color TFT, industrial-grade multi-touch technology and access to a proven Delem user interface. |

- Technical Specifications -

| Pure ES Series Press Brake | |||||

| Machine Parameter | ES-20T1000 | ES-30T1250 | ES-40T1600 | ES-60T2500 | ES-100T3200 |

| Pressing Force | 200KN | 200KN | 400KN | 600KN | 1000KN |

| Max.bending Length | 1000mm | 1250mm | 1600mm | 2500mm | 3200mm |

| Distance Between Frames | 900mm | 1100mm | 1400mm | 2300mm | 2600mm |

| Max Opening Height | 420mm | 470mm | 470mm | 470mm | 530mm |

| Ram Stroke | 120mm | 150mm | 150mm | 150mm | 200mm |

| Throat Depth | 250mm | 250mm | 300mm | 350mm | 400mm |

| Approach Speed | 250mm/s | 300mm/s | 250mm/s | 220mm/s | 180mm/s |

| Working Speed | 0.5-30mm/s | 0.5-30mm/s | 0.5-20mm/s | 0.5-20mm/s | 0.5-20mm/s |

| Return Speed | 250mm/s | 300mm/s | 250mm/s | 220mm/s | 180mm/s |

| X-axis Back Gauge Stroke | 300mm | 500mm | 500mm | 500mm | 500mm |

| R-axis Back Gauge Stroke | 100mm | 100mm | 100mm | 150mm | 150mm |

| Y1, Y2 axis accuracy | ±0.01mm | ||||

| X and R axis accuracy | ±0.01mm | ||||

| CNC Control Axis | Y1,Y2, X, R | Y1,Y2, X, R | Y1,Y2, X, R, Z1, Z2 | Y1,Y2, X, R, Z1, Z2,V | Y1,Y2, X, R, Z1, Z2,V |

| Main servo motor | 11KW | 13KW | 15KW | 30KW | 30KW |

| CNC System | ETC-16T | ||||

| Length x Width x Height(mm) | 1200x800x2000 | 1500x900x2100 | 2000x1200x2300 | 2900x1800x2400 | 4000x1900x2600 |

| Weight | 2000kg | 2600kg | 3800kg | 5500kg | 12000kg |

|