| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Smart HTC Series CNC Press Brake |

|---|---|

| Brand Name: | genuo |

| Model Number: | HTC-40T/63T/80T/100T |

| Certification: | M.2019.206.C3862 |

| Place of Origin: | China |

| MOQ: | 1 |

| Payment Terms: | L/C, T/T, D/P, D/A |

| Supply Ability: | 1 Set/Sets Every 15~35 days |

| Delivery Time: | 90 days |

| Packaging Details: | carton box |

| Machine Name: | Torsion-Bar NC Bending Machine |

| Application: | Metal Sheet Mini Press Brake |

| CNC Controller: | Estun E21/E300P |

| Machine Voltage: | 220V/380V/415V/440V/customized |

| Machine Color: | Customer Choose |

| Hydraulic Valve: | Rexroth Hydraulic Valve |

| After-sales Service: | Internet Technology Provider |

| Advantage: | Low Price |

| value-added services: | Presented Two years warranty |

| Length specification: | 1250/1600/2500/3200 mm |

| Automation: | Manual/ semi-automatic |

| Price: | negotiable |

| Company Info. |

| Maanshan Genuo Machinery Manufacturing Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

On Slae WC67Y Small NC Press Brake Machine Mini Bending Machine 40T

→ Product Introduction:

Esay series press brakes adopts classic design - GENUO EASY HTC series CNC bending machines are the selling small

sheet metal bending machine worldwide. The high-strength frame and

simple torsion bar structure ensure the synchronization

of both ends of the press brake and the smooth operation of the

ram. It can bring stable bending performance. High quality

hydraulic system can burst out strong power and bending speed.

Simple operation, low maintenance cost, more economical production

& versatility Affordable price is a very good choice for simple

bending workpieces. 30T ~ 300T optional.

→ Advantages of Genuo :

1. We are an ODM and OEM company that can produce machines according to the specifications, designs, and customer requirements of world-renowned brands.

2. Whatsmore, We have professional technology, advanced processing equipment, scientific quality management, continuously improving production capacity and creativity, which lay a solid foundation for the sustainable development of our company.

3. Our products have CE certification and SGS certification, and our factory has professional equipment testing and strict quality control.

4. For our customers, we can provide comprehensive customized and high-performance solutions to them, as well as great after-sales service, This is something that our competitors cannot meet.

5. The production process meets the highest standards to ensure exceptional quality and perfect detail. During the delivery period, we can customize high-performance solutions and timely after-sales service for you.

6. GENUO provides a variety of tooling solutions to meet your different production needs. Not only that, we are also experts in the field of bending tools. If you have any special bend, our engineers will customize special tools for each workpiece.

→ Product Configuration:

Standard Equipment:

| Feature: < X axis and Y axis numerical control < Motorized variable frequency drive < Depth adjustment for different angles < Adapt to sheet metal with different thickness < More efficient and variable bending < Powerful and durable bending power < Minimize oil leakage of the machine < Single/Tandem optional |

→ Machine Detail :

ESTUN E21ESTUN E21 HD LCD display, with both Chinese and English language options, X, Y-axis intelligent positioning program.Control+converter via bus communication, ram and back gauge can be positioned fastand accurately. Easy operation with cost performance and high efficiency. | Torsion-Bar Structure High quality torsion-bar structure, shaft body adopts the traditionalforging and tempering process, which has high strength, good elasticity and adjustable design. | Backgauge System Establishing the right back gauge for your projects will allow for increased part production and precision. From intricate parts which typically require more axes to large quantities that require more time. |

Tooling and Clamps GENUO provides a variety of tooling solutions to meet your different production needs.Not only that, we are also experts in the field of bending tools. If you have any special bend, our engineers will customize special tools for each workpiece. | Siemens Main Motor Using Germany Siemens main motor guarantee the machine service life andimprove the machine working stability. Reasonable matching makes the machine burst out strong and lasting pressure. | Rexroth Hydraulic Valve The hydraulic valve is controlled in a variety of ways to start the hydraulic valve element to open or close, regulating the flow rate. Make the machine run safely and stably, extend the service life. |

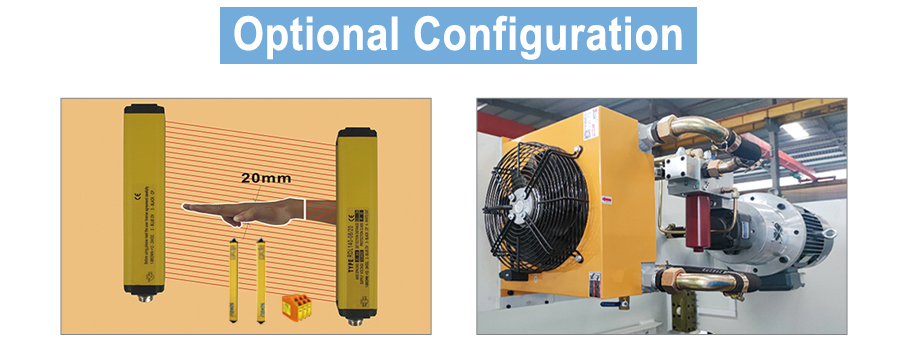

Light Curtain Switch The light curtain switch is applicable to some automatic factories to realize the regional management of machines.Ensure that the machine is stopped when the operator checks and repairs the machine or appears in the wrong position;Improve safety. | Oil Fan Cooling Device In some tropical areas or uninterrupted operation is required, oil cooling device can be configured to avoid overheating of hydraulic oil and ensure continuous normal operation of the machine |

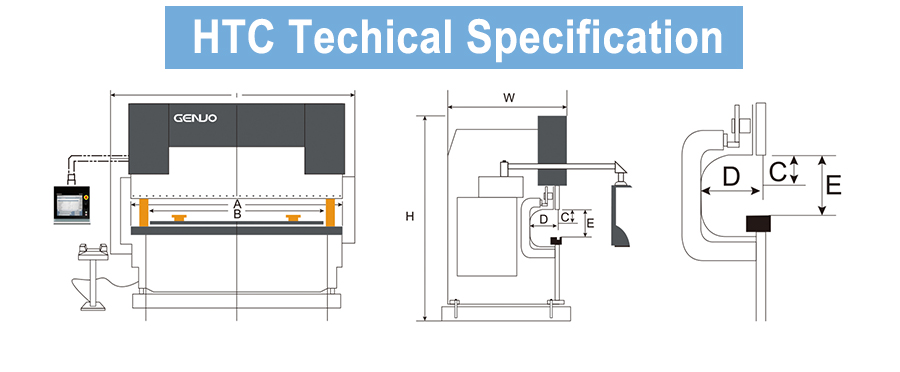

— HTC PRO Techical Specification—

| A | B | D | E | C | |||||

| Model | Nominal Pressure | Length of Table | Distance Between Columns | Throat Death | Open Height | Ram Strokes | Motor Power | Approx Weight | Overall Dimension |

| (KN) | (mm) | (mm) | (mm) | (mm) | (mm) | (kw) | (kg) | (L x W x H)(mm) | |

| 30T/1600 | 300 | 1600 | 1250 | 200 | 220 | 80 | 3 | 1500 | 1650*1200*1700 |

| 40T/1600 | 400 | 1600 | 1250 | 200 | 240 | 100 | 4 | 2600 | 2000*1200*1900 |

| 40T/2500 | 400 | 2500 | 2030 | 250 | 340 | 100 | 4 | 3000 | 2500*1200*1900 |

| 63T/2500 | 630 | 2500 | 2050 | 250 | 340 | 120 | 5.5 | 4000 | 2500*1350*2100 |

| 63T/3200 | 630 | 3200 | 2510 | 250 | 340 | 120 | 5.5 | 4800 | 3200*1350*2100 |

| 80T/2500 | 800 | 2500 | 2050 | 250 | 350 | 120 | 5.5 | 4500 | 2500*1400*2150 |

| 80T/3200 | 800 | 3200 | 2510 | 250 | 350 | 120 | 5.5 | 5500 | 3200*1400*2150 |

| 100T/2500 | 1000 | 2500 | 2050 | 320 | 380 | 120 | 7.5 | 5000 | 2500*1500*2200 |

| 100T/3200 | 1000 | 3200 | 2510 | 320 | 380 | 120 | 7.5 | 6500 | 3200*1500*2300 |

| 100T/4000 | 1000 | 4000 | 3100 | 320 | 380 | 120 | 7.5 | 7600 | 4000*1500*2400 |

| 125T/3200 | 1250 | 3200 | 2510 | 320 | 380 | 120 | 7.5 | 7000 | 3200*1600*2350 |

| 125T/4000 | 1250 | 4000 | 3100 | 320 | 380 | 120 | 7.5 | 8500 | 4000*1600*2450 |

| 160T/2500 | 1600 | 2500 | 2050 | 320 | 450 | 200 | 11 | 8000 | 2500*1650*2700 |

| 160T/3200 | 1600 | 3200 | 2510 | 320 | 450 | 200 | 11 | 10000 | 3200*1650*2800 |

| 160T/4000 | 1600 | 4000 | 3100 | 320 | 450 | 200 | 11 | 11000 | 4000*1650*2800 |

| 160T/5000 | 1600 | 5000 | 4000 | 320 | 450 | 200 | 11 | 14000 | 5000*1750*3100 |

| 160T/6000 | 1600 | 6000 | 4600 | 320 | 450 | 200 | 11 | 17000 | 6000*1750*3300 |

| 200T/3200 | 2000 | 3200 | 2600 | 320 | 540 | 250 | 15 | 13000 | 3200*1900*3100 |

| 200T/4000 | 2000 | 4000 | 3300 | 320 | 540 | 250 | 15 | 14500 | 4000*1900*3100 |

| 250T/3200 | 2500 | 3200 | 2600 | 400 | 580 | 250 | 18.5 | 17000 | 3200*2100*3150 |

| 250T/4000 | 2500 | 4000 | 3300 | 400 | 580 | 250 | 18.5 | 18500 | 4000*2100*3150 |

| 250T/5000 | 2500 | 5000 | 4000 | 400 | 580 | 250 | 18.5 | 22000 | 5000*2100*3200 |

| 250T/6000 | 2500 | 6000 | 4500 | 400 | 580 | 250 | 18.5 | 25500 | 6000*2100*3200 |

| 300T/3200 | 3000 | 3200 | 2600 | 400 | 580 | 250 | 18.5 | 20500 | 3200*2200*3200 |

| 300T/4000 | 3000 | 4000 | 3300 | 400 | 580 | 250 | 18.5 | 22500 | 4000*2200*3200 |

| 300T/5000 | 3000 | 5000 | 4000 | 400 | 580 | 250 | 18.5 | 25000 | 5000*2200*3200 |

| 300T/6000 | 3000 | 6000 | 4600 | 400 | 580 | 250 | 18.5 | 27500 | 6000*2200*3200 |

| 400T/4000 | 4000 | 4000 | 3300 | 400 | 580 | 250 | 22 | 26500 | 4000*2400*3200 |

| 400T/5000 | 4000 | 5000 | 4000 | 400 | 580 | 250 | 22 | 31500 | 5000*2400*3200 |

| 400T/6000 | 4000 | 6000 | 4400 | 400 | 580 | 250 | 22 | 36000 | 6000*2400*3200 |

| 500T/4000 | 5000 | 4000 | 3300 | 500 | 620 | 320 | 30 | 31000 | 4000*2650*3200 |

| 500T/5000 | 5000 | 5000 | 4000 | 500 | 620 | 320 | 30 | 36500 | 5000*2650*3200 |

| 500T/6000 | 5000 | 6000 | 4410 | 500 | 620 | 320 | 30 | 43500 | 6000*2700*3200 |

| 500T/7000 | 5000 | 7000 | 5400 | 500 | 620 | 320 | 30 | 53000 | 7000*2700*3200 |

| 600T/4000 | 6000 | 4000 | 3300 | 500 | 620 | 320 | 37 | 42500 | 4000*2700*3200 |

| 600T/5000 | 6000 | 5000 | 4000 | 500 | 620 | 320 | 37 | 48000 | 5000*2700*3250 |

| 600T/6000 | 6000 | 6000 | 4600 | 500 | 620 | 320 | 37 | 53500 | 6000*2700*3300 |

| 600T/7000 | 6000 | 7000 | 5400 | 500 | 620 | 320 | 37 | 60000 | 7000*2900*3500 |

→ Machine Application:

1. In the decoration industry, the production of stainless steel plates, doors and Windows;

2. Reprocessing of sheet metal products in the electrical industry;

3. In the kitchen catering industry, various specifications of

stainless steel kitchenware;

4. In the communication industry, electric poles, road light poles,

communication poles, traffic signal poles, etc.;

5. In the automotive industry, secondary processing of sheet metal;

6. In the aerospace industry, high-precision CNC bending mechanisms

are used as high-precision products.

→ After-sale guarantee :

1. Free training Professional guidance and training to ensure the

normal operation

2. Years WarrantySuper long-term warranty is our confidence in

quality and commitment

3. Lifelong service Professional team to ensure that your machine

is super long service.

|