| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Pillow Packing Machine |

|---|---|

| Brand Name: | Waylead |

| Model Number: | WZ-400 |

| Certification: | / |

| Place of Origin: | Shanghai |

| MOQ: | 1 set |

| Price: | Negotiable |

| Payment Terms: | L/C, T/T, Western Union |

| Supply Ability: | 300 sets per year |

| Delivery Time: | 30 days |

| Packaging Details: | International standard packaging for shipping |

| Function: | Filling,Wrapping, Sealing |

| Packaging Type: | Bags, Film, Pouch |

| Packaging Material: | Plastic |

| Production Capacity: | 30-500 bags/min |

| Weight (KG): | 400KG |

| Automatic Grade: | Automatic |

| Warranty: | 12 months |

| Type: | Multi-Function Packaging Machine |

| Condition: | New |

| General power: | 3.1 Kw |

| Name: | Food Pillow Packing Machine |

| Usage: | automatic horizontal pillow packing machine |

| Company Info. |

| Shanghai Waylead Intelligent Technology Co.,Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

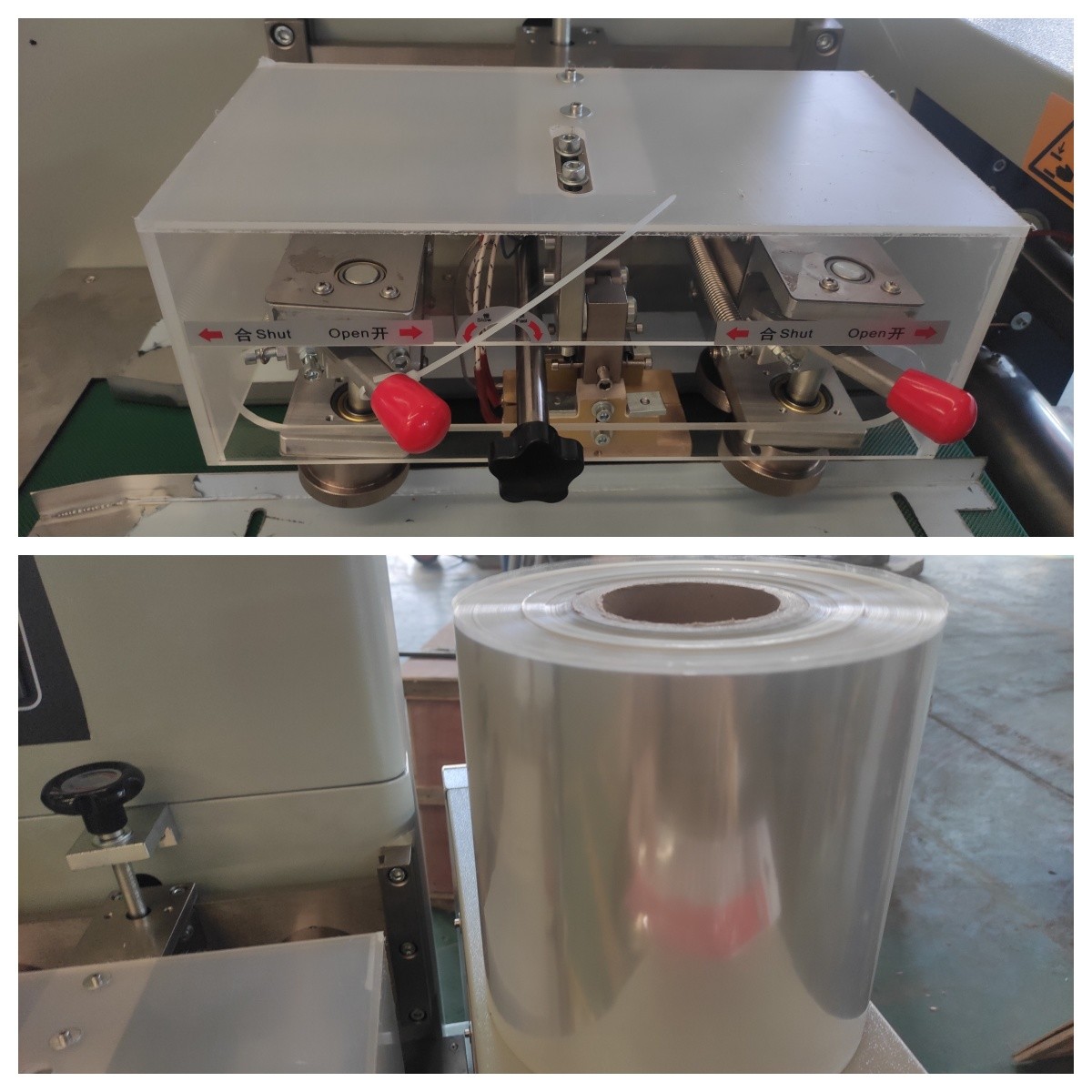

| Model | WZ-400 |

| Packaging specifications | Single jaw: length 120~500mm, width 35-160mm, height 5-60mm |

| Packaging specifications | Double jaws: length 60~350mm, width 35-160mm, height 5-60mm |

| Packaging specifications | Three jaws: length 45~100 mm, width 35-160mm, height 5-30mm |

| Packing Speed | Single jaw: 30~150 packs/min Double jaws: 30-300 packs/min Triple jaws: 30-500 packs/min |

| Film Size | 90-400mm |

| Packing Film type | PP,PVC,PE,PS,EVA,PET,PVDC+PVC,etc |

| Weight | 400KG |

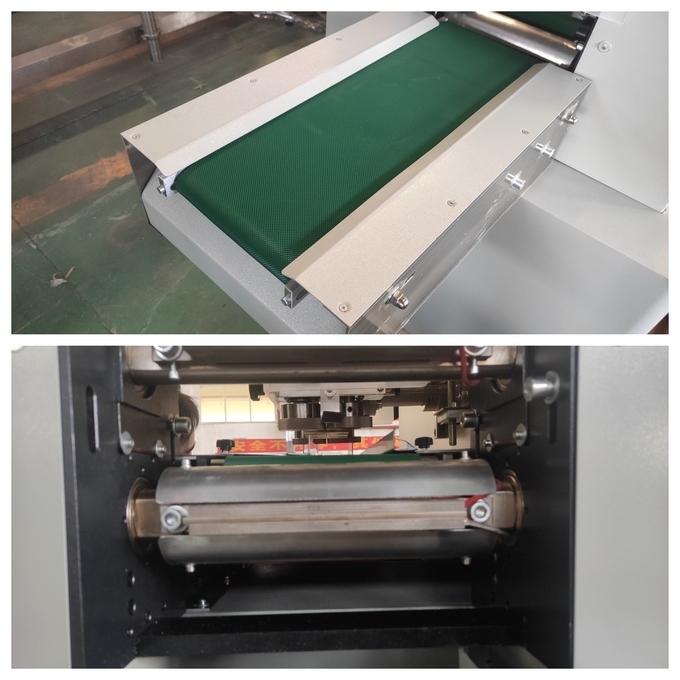

| Dimension | 4000×930×1370 mm |

Crafted to handle an extensive array of typical solid items, this adaptable packaging machine is ideal for packaging a variety of products like cakes, bread, cookies, candies, medications, everyday essentials, hardware components, cardboard boxes, and trays. Its versatility enables seamless and effective packaging operations spanning different industries and product types.

Q1:Can the pillow packaging machine accommodate different packaging

sizes and shapes?

A1:Yes, most pillow packaging machines can be adjusted to

accommodate various packaging sizes and shapes. They often offer

flexibility in terms of pouch width, length, and adjustable forming

systems to cater to different product dimensions. It is important

to choose a machine that provides the necessary customization

options for your specific packaging requirements.

Q2:What technical support and warranty are provided with the pillow

packaging machine?

A2:We can offer technical support and a warranty for their

packaging machines. Ensure that the supplier provides comprehensive

training for machine operation and maintenance. Additionally,

inquire about the warranty period, available spare parts, and

post-sales support to ensure a smooth and trouble-free packaging

process.

Q3:Can the pillow packaging machine integrate with other production

line equipment?

A3:Many pillow packaging machines can be integrated into existing

production lines, allowing for seamless workflow and increased

automation. It is essential to communicate your integration needs

with the machine supplier to ensure compatibility and to streamline

your packaging operations.

Q4: I'm worried that I don't know how to operate your machine?

Answer: Do not worry. Our top quality automatic packaging system is

servo controlled, which greatly simplifies the difficulty of

operation and commissioning. Most of the daily operation of the

machine can be conducted by a few start-stop buttons and HMI. If

you have different products or packages that need to be changed, we

can provide instructional videos to give you step-by-step tutorial.

Also, the HMI has memory function, which is convenient for you to

reload the settings in the future.

Specializing in comprehensive turn-key solutions for packaging processing projects and fruit/vegetable processing lines, Shanghai Waylead Intelligent Technology Co., Ltd. concentrates on packaging equipment, robot applications, fruit and vegetable processing machinery, and more. It is dedicated to serving various industries including fruit and vegetable processing, baking, snack foods, freeze-drying, powder processing, sauces, hardware, chemicals, and more, offering all-encompassing professional services. With 15 years of industry expertise and a portfolio of numerous domestic and international engineering projects, the company delivers top-notch equipment and services, ensuring customers receive high-quality solutions and exceptional support.

Packaging: We will pack the products carefully and safely deliver them to

your hands.

lf you have any other packaging requirements, please contact us.

|