| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

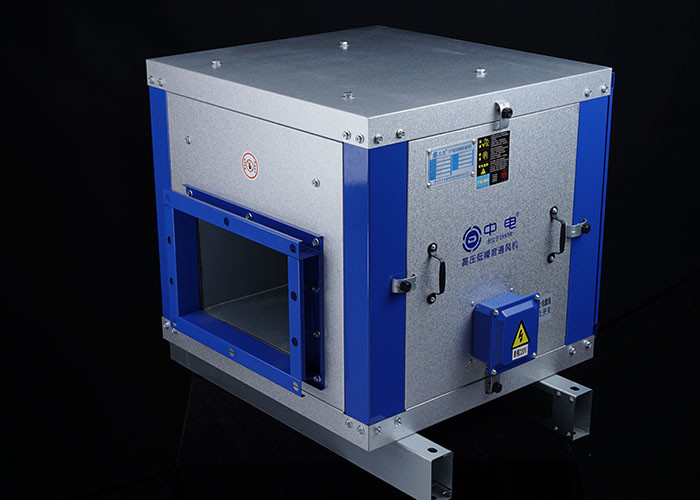

| Categories | Cabinet Centrifugal Fan |

|---|---|

| Brand Name: | Available for ODM |

| Model Number: | DT55-200 |

| Certification: | CE |

| Place of Origin: | China Foshan |

| MOQ: | 1 |

| Price: | Contact Us |

| Payment Terms: | T/T |

| Supply Ability: | 5000 |

| Delivery Time: | 3-8 work days |

| Packaging Details: | Carton packaging,1 units per carton |

| Applicable Industries: | Restaurant, Home Use, Other, Hospital, laboratory, graduate School, beauty salon, office |

| Electric Current Type: | AC |

| After-sales Service Provided: | Online support |

| Voltage: | 380V/50Hz |

| Customized support: | OEM, ODM |

| Warranty: | 1 Year |

| Core Components: | Motor |

| Mounting: | Duct Fan |

| Company Info. |

| Guangdong Zhongdian Jiajin Environmental Technology Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

Product Use

Applications:

Product Motor

Advantages of High Static Pressure Copper-Wire Motors:

1. Outstanding Performance

High static pressure means the motor can generate significant air pressure, allowing it to overcome substantial resistance in complex ventilation systems and achieve long-distance air supply or exhaust. Whether in large commercial buildings, industrial facilities, or high-rise structures, it ensures effective air circulation. Copper-wire motors, with their excellent electrical conductivity, reduce resistance loss and enhance motor efficiency. Compared to motors made of other materials, copper-wire motors can deliver greater torque at the same power level, providing stronger动力 for the ventilation system.

2. Stable and Reliable

The manufacturing process for copper-wire motors is well-established, ensuring consistent quality. The high static pressure design allows the motor to handle substantial loads during operation with fewer failures. Additionally, copper’s excellent heat resistance and oxidation resistance guarantee stable performance over long periods, reducing downtime caused by motor failures and enhancing system reliability.

3. Energy-Efficient

Copper wire’s low resistance results in relatively low energy loss during motor operation. The high static pressure design enables the motor to achieve high airflow and pressure at lower speeds, thereby reducing energy consumption. This results in significant savings on electricity costs over time. Moreover, the efficient motor reduces environmental impact, aligning with energy-saving and emission-reduction goals.

4. Low Noise

High static pressure copper-wire motors typically incorporate advanced noise reduction technologies, such as optimized motor structures and soundproof materials. Consequently, the noise produced during operation is relatively low, minimizing disruption to the surrounding environment. This is especially important in quiet environments like hospitals, schools, and libraries.

5. Long Service Life

Copper-wire motors are highly durable with a long service life. The high static pressure design allows them to withstand various challenging working environments without damage. Additionally, their excellent heat dissipation extends the motor’s lifespan. Compared to other types of motors, copper-wire motors have lower maintenance costs, alleviating concerns for users.

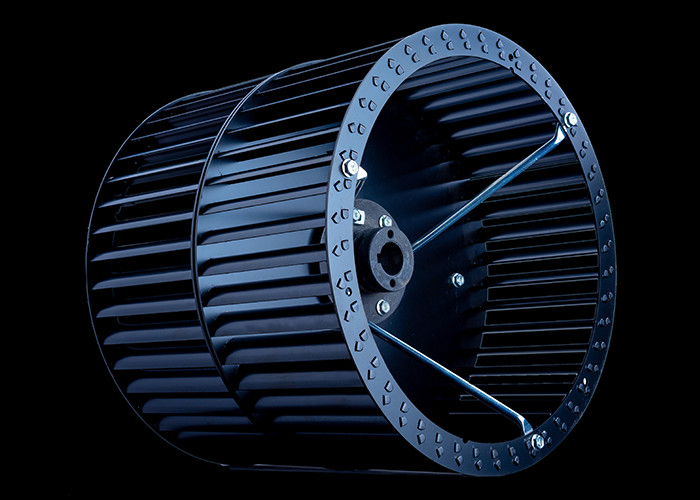

Product Impeller

Advantages of All-Metal Impellers Compared to Plastic Impellers:

Product Specifications

High Strength: Metal impellers typically offer higher strength, allowing them to withstand greater stress and loads. They are well-suited for high-load and high-speed applications, and are less likely to deform or suffer damage, ensuring stable operation of the equipment.

Excellent Wear Resistance: Metal materials generally have superior wear resistance, making them more durable against abrasion and friction. This results in a longer service life for all-metal impellers, reducing the frequency of replacements and lowering both operational costs and maintenance efforts.

Strong High-Temperature Tolerance: Metal materials maintain stable performance in high-temperature environments and are less prone to deformation or failure. They are suitable for applications requiring high-temperature conditions, such as high-temperature ventilation systems and heaters.

Good Dynamic Balancing: The density of metal impellers is relatively uniform, allowing for high-precision machining and balancing. This results in excellent dynamic balancing performance, minimizing vibration and noise during operation and enhancing the smoothness and comfort of the equipment.

| Model Numb | Voltage | Ffrequency | Rotating speed | Alr volume | Total Pressure | Sound Level | Power | Weight |

| (V) | (Hz) | (r/min) | (m2/h) | (Pa) | (dB) | (W) | (kg) | |

| DT11-36 | 220/380 | 50 | 1450 | 3600 | 562 | 57 | 1.1 | 49 |

| DT13-48 | 220/380 | 50 | 1450 | 4800 | 623 | 63 | 1.5 | 58 |

| DT18-61 | 220/380 | 50 | 1450 | 6100 | 673 | 68 | 2.2 | 70 |

| DT25-81 | 220/380 | 50 | 1450 | 8100 | 781 | 69 | 3 | 79 |

| DT32-100 | 220/380 | 50 | 1450 | 10000 | 810 | 75 | 3.8 | 84 |

| DT42-120 | 380 | 50 | 1450 | 12000 | 830 | 78 | 5 | 100 |

| DT48-150 | 380 | 50 | 1450 | 15000 | 860 | 78 | 5.5 | 101 |

| DT55-200 | 380 | 50 | 1450 | 20000 | 870 | 79 | 6 | 122 |

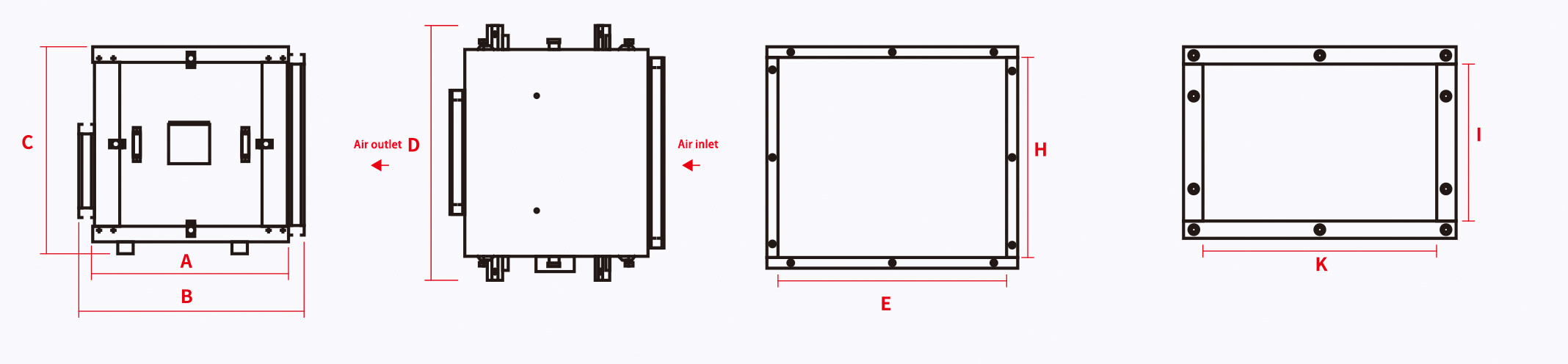

Product Dimensions Diagram

Product Dimensions and Specifications

| Model Numb | A | B(Length) | C(Height) | D(Width) | Air Inlet (Internal Diameter) | Air Outlet (Internal Diameter) | Flange Thickness | ||

| E(Length) | H(Height) | l(Height) | K(Length) | ||||||

| DT11-36 | 560 | 660 | 613 | 750 | 467 | 428 | 250 | 305 | 30x30 |

| DT13-48 | 570 | 668 | 650 | 780 | 497 | 460 | 210 | 335 | 30x30 |

| DT18-61 | 620 | 718 | 705 | 860 | 580 | 515 | 235 | 355 | 30x30 |

| DT25-81 | 650 | 748 | 740 | 910 | 630 | 550 | 250 | 380 | 30x30 |

| DT32-100 | 650 | 748 | 740 | 910 | 630 | 550 | 250 | 380 | 30x30 |

| DT42-120 | 725 | 823 | 815 | 962 | 679 | 625 | 280 | 355 | 30x30 |

| DT48-150 | 750 | 848 | 815 | 1000 | 717 | 625 | 380 | 405 | 30x30 |

| DT55-200 | 780 | 879 | 840 | 1030 | 747 | 650 | 380 | 415 | 30x30 |

|