| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Wiping Rags Baler |

|---|---|

| Warranty: | 1 Year |

| Type: | Other |

| Applicable Industries: | Manufacturing Plant, Farms, Retail, OTHER |

| Showroom Location: | United Kingdom, United States, Australia |

| Video outgoing-inspection: | Provided |

| Machinery Test Report: | Provided |

| Warranty of core components: | 1 Year |

| Core Components: | Engine, Motor, Pressure vessel, Gear |

| Condition: | New |

| Application: | Textiles |

| Packaging Type: | Bags |

| Packaging Material: | Plastic |

| Automatic Grade: | Automatic |

| Driven Type: | Electric |

| Voltage: | 220V/380V |

| Power: | 7.5kw |

| Place of Origin: | China |

| Brand Name: | UT |

| Weight: | 710 KG |

| Dimension(L*W*H): | 2300*5700*2900mm |

| Key Selling Points: | High-accuracy |

| Name: | used clothes and textile compress baler machine |

| Product name: | West clothes |

| Packing material: | Plastic bags |

| Keyword: | Hydraulic Press Packing |

| Function: | packing machine |

| Usage: | Compress Waste Paper |

| Suitable for: | Used Clothes |

| Key words: | Packaging Machineries |

| Machine type: | Horizontal Packing Machine |

| Main Function: | Baler Machine For Used Clothes recycling |

| Price: | Negotiation |

| MOQ: | 1 |

| Packaging Details: | wooden box |

| motor: | 220v/380v/415v/customzied |

| color: | customzied |

| Company Info. |

| Gongyi UT Machinery Trade Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

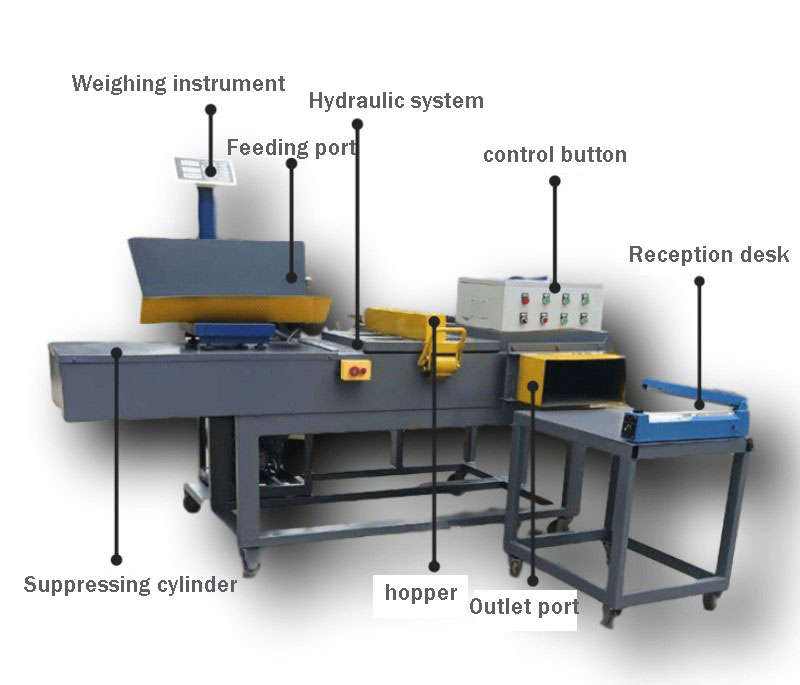

Fully Automatic Horizontal Hydraulic Waste Clothes Bagging Machine Vacuum Compress Foam Baler Machine For Used Clothes recycling

♥.Description of used clothes baling machine:

♥.Technical parameters of sawdust press baler machine:

Model | UT-60 |

Press Force | 10t |

Motor Power | 5.5kw |

Voltage | 380/400/415/460 etc |

Bale Size | 400*400*180mm |

Bale Weight | 1~20kgs |

Output | 120bales per hour |

Dimensions | 2660*1760*1550mm |

Weight | 715kg |

♥.Features of used clothes baling machine :

Pre-sale:

1. Suggest to client suitable models of as customer need.

2. Introduce machine's structure and features in detail, explain

the price component;

3. answer client concerned questions.

After-sale:

1. Start production as soon as receiving down payment.

2. Send photos of machine in manufacturing and finished photos to

client, for your better

learn about the machine's condition.

3. Delivery machine in time, taking photos during loading, so you

can "remote monitoring"

your goods.

4. Documents and certificate available in time.

5. Manual documents available. Engineer can be sent to client site

for installation instruction.

|