Industrial Cleaning And Drying Equipment For Metalware With

Comprehensive Functions

Industrial cleaning and drying equipment for metalware with

comprehensive functions is a highly integrated advanced

equipment that provides a one-stop solution for the cleaning and

drying of metalware.

1. Working principle

This equipment integrates multiple advanced technologies. First, in

the cleaning stage, through the combined application of

high-pressure spraying, ultrasonic cleaning, and soaking, dirt, oil

stains, and impurities on the surface and inside of metalware

are completely removed. High-pressure spraying can wash off most of

the attached pollutants with strong impact force;

ultrasonic cleaning uses the cavitation effect to generate tiny

bubbles in the liquid. The energy released when the bubbles burst

can penetrate into the fine parts of metalware and effectively

remove dirt from hard-to-reach areas. The soaking process helps

soften and dissolve stubborn stains. In the drying stage, precisely

controlled temperature and air flow are used to quickly

evaporate the moisture on the surface of metalware and make it dry

quickly. At the same time, the equipment may also be

equipped with advanced sensors and control systems to monitor

parameters such as temperature, humidity, and air flow in real

time to ensure the efficiency and stability of the drying process.

2. Advantages

Comprehensive functions: Integrating multiple functions such as

cleaning, drying, rust prevention, and disinfection greatly

simplifies the processing flow of metalware. It can not only remove

dirt and moisture but also prevent metalware from rusting and

disinfect it to ensure product quality and safety. High efficiency

and energy saving: Adopting an advanced energy management system to

optimize energy consumption during the cleaning

and drying processes and reduce operating costs. At the same time,

efficient cleaning and drying technologies can complete

the processing tasks of a large number of metalware in a short time

and improve production efficiency. High degree of

automation: Equipped with an intelligent control system to realize

automated operation, reduce manual intervention, and

lower labor intensity. Operators only need to perform simple

settings and monitoring, and the equipment can automatically

complete a series of work such as cleaning and drying. Strong

adaptability: It can adapt to the cleaning and drying needs of

metalware of different types, sizes, and materials. Whether it is

small precision metal parts or large metal containers, they can

be effectively processed in this equipment.

3. Application scenarios

Widely used in various fields such as metal processing enterprises,

metal product manufacturing enterprises, catering industry,

and healthcare. In metal processing enterprises, it can be used to

clean and dry various metal parts such as automotive parts

and mechanical parts to ensure the cleanliness of products before

assembly. In metal product manufacturing enterprises, such

as kitchenware manufacturing and tableware production industries,

this equipment can efficiently process a large number of

metalware and improve product quality and production efficiency. In

the catering industry, it can be used to clean and disinfect

various metal tableware to ensure food safety and hygiene. In the

healthcare field, metal parts in medical devices can be cleaned

and dried to meet strict hygiene requirements.

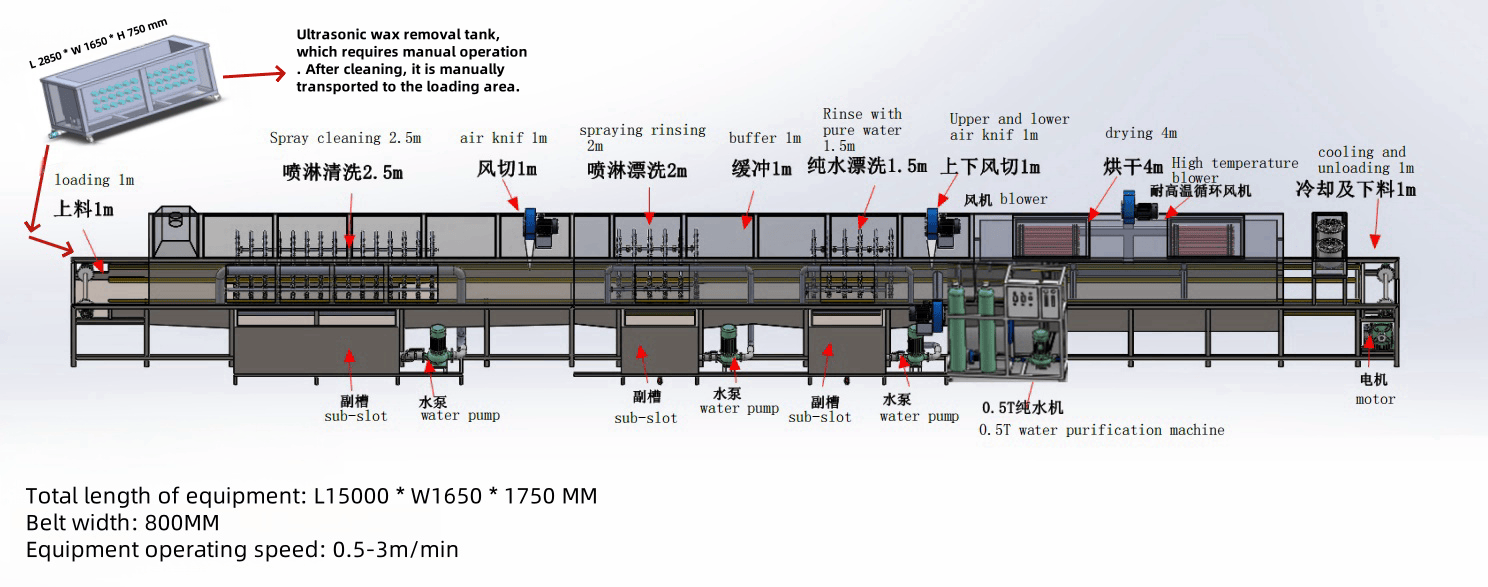

Equipment Parameters:

Tank Body

Structure | Internal effective size | Inner tank size: L2600×W1400×H500mm

Approximate overall size: L2850W1650H750mm (subject to the actual size) |

| Heating method | Electric heating 12KW |

| Material | The inner tank adopts "SUS304" 2.5mm Zhangjiagang Posco stainless

steel plate.

The non-radiating surface adopts SUS304 T = 2.0mm, and the outer

door panel adopts 1.0mm stainless steel. |

| Outer frame of the cleaning tank | It is fabricated by welding stainless steel 40401.5 square tubes, with a sturdy and durable structure. |

| Structure | The ultrasonic transducers are adhered to the bottom of the tank

(bottom vibration type), and four corner wheels are configured at

the bottom. |

| Ultrasonic transducer | Adopt imported wafer transducers of "HESEN" brand and imported

bonding technology. The total number of ultrasonic transducers is

200, with a frequency of 28KHZ and 60W each. |

| Total ultrasonic power | 12KW |

| Time control

| It is built-in in the generator and the time is adjustable from 0

to 999 minutes. |

| Power supply system | Ultrasonic generator | The generator adopts 4 sets of internationally leading IGBT modules

and power tubes for control to ensure strong and stable output

power. Xiantai's unique sweeping frequency technology ensures no

dead corners in cleaning.

It has functions such as continuously adjustable power, sweeping

frequency, timing adjustment, start/stop, etc. |

| Component part | All are imported high-quality components. |

| Other | | Configure a dedicated control box rack. There are two independent

generators placed on the control box rack.

The ultrasonic power cord is 3 meters long. |

| After-sales服务sevre | Transport | |

| The equipment is warranted for one year and maintained for life. |