| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Steel Structure Warehouse |

|---|---|

| Brand Name: | XGZ |

| Model Number: | BYSS-016 |

| Certification: | CE,ISO |

| Place of Origin: | China |

| MOQ: | 1 square |

| Price: | US $19-79 square meter |

| Payment Terms: | L/C, T/T, Western Union |

| Supply Ability: | 5000 Ton Per Month |

| Delivery Time: | 45 work days |

| Packaging Details: | standard containers |

| Company Info. |

| Qingdao Xinguangzheng Husbandry Co., Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

Customized Prefabricated Steel structure warehouse workshop

| Main Parts | Item Name | Specification |

| Main Steel Frame | Steel Column | Q235B, Q345B H shape, Box, Steel pipe, Hot rolled sheet |

| Steel Beam | Q235B, Q345B H shape, Steel Truss, Hot rolled sheet | |

| Supporting System | Brace | Q235B, Q345B Steel rod, Steel pipe, Angle steel |

| Roof Purlin | C or Z shape, Steel purlin | |

| Wall Purlin | Q235B, Q345B C or Z shape, Steel purlin | |

| Roof | Single colorful corrugate steel sheet, Sandwich panel with EPS, Rock wool, PU, Glass wool etc., | |

| Wall | Single colorful corrugate steel sheet, Sandwich panel with EPS, Rock wool, PU, Glass wool etc., | |

| Accessories | Bolts | Ordinary, High strength |

| Gutter | Galvanized Steel plate, Stainless steel | |

| Windows | Aluminum alloy-Glass, Aluminum alloy-shutter, PVC | |

| Doors | Sliding or Rolling door | |

| Downpipes | PVC pipe, Color steel pipe | |

| Edge Cover | Made of color steel sheet thickness 0.5mm | |

| Ventilator | Stainless steel | |

| Crane | Crane in 5 tons to 20 tons |

High quality raw materials

Products overview

Company profile

Qingdao Xinguangzheng Steel Structure Co., Ltd. is a company specializing in designing, developing, manufacturing, selling steel structures and undertaking various kinds of steel structural projects. We have possessed more than 80 sets of large precise and domestically advanced processing equipments, including large gantry planing machines, automatic submerged arc welding machines, assembling machines, slitters, shot blasting machines and so on. Various types of steel building materials produced by our company, such as color-coated steel tiles and sandwich panels, are widely used in different areas. Our products are not only sold all over the country, but also exported to Japan, South Korea, the United States, UAE, Australia, Africa and other countries and regions.

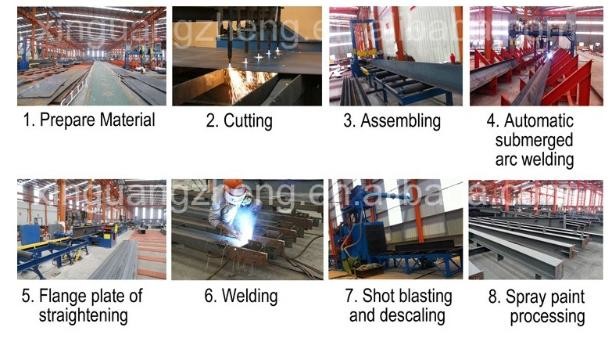

Productive process

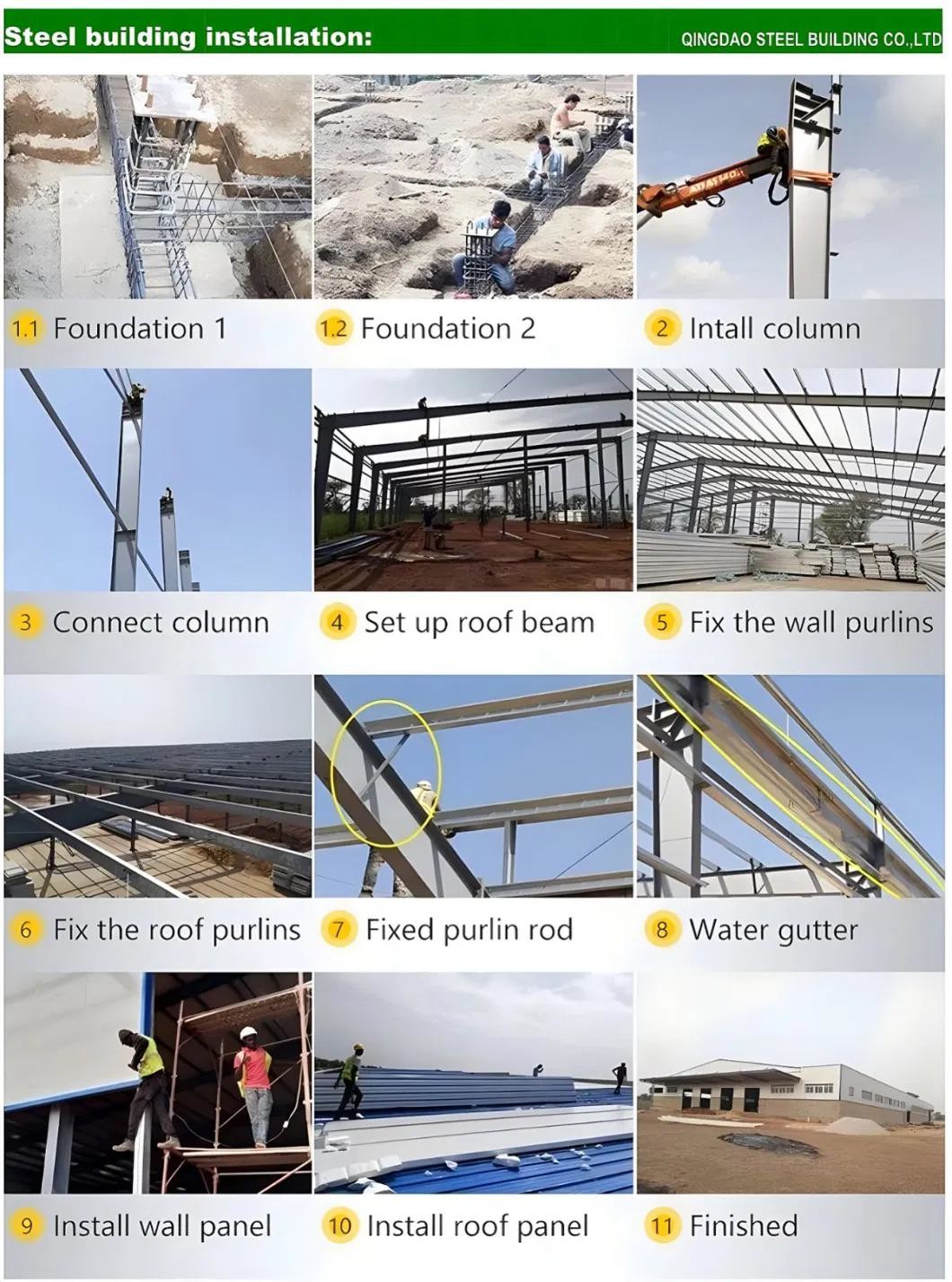

Installation guide

Our advantage

1. Efficient prefabrication, saving time and effort

It adopts a fully prefabricated steel structure system. All

components are precisely produced in the factory, and standardized

processes ensure accuracy. Only simple assembly is required on

site, and the installation speed is over 50% faster than that of

traditional buildings, significantly shortening the construction

period. Modular design reduces the demand for human resources,

lowers labor costs, and at the same time avoids on-site

construction pollution, achieving rapid delivery.

2. Flexible customization, beautiful and diverse

Supports personalized customization design, and the layout can be

flexibly adjusted to meet different functional requirements (such

as residences, factories, exhibition halls, etc.). It offers a

variety of appearance style options. The walls and roofs can be

matched with nearly a hundred colors and materials, easily matching

the surrounding environment or project characteristics, and

balancing practicality and aesthetic value.

3. Lightweight structure, economically efficient

The main body is made of high-strength lightweight steel, with a

self-weight 60%-70% lighter than that of concrete structures,

significantly reducing the cost of the foundation. Modular design

is easy to disassemble and rebuild in different locations, with a

high reuse rate and cost savings throughout the entire life cycle.

It is particularly suitable for temporary buildings or projects

that need to be relocated.

4. Quick disassembly and assembly, flexible turnover

The all-bolt connection design eliminates the need for welding or

complex tools, allowing a single person to complete the basic

installation. The components can be disassembled as a whole and

reused, and the dismantling time is only one third of that of

traditional buildings. It is particularly suitable for emergency

engineering, seasonal facilities or projects that require frequent

renovations, and can flexibly adapt to dynamic demands.

5. Green and environmentally friendly, recyclable

100% recyclable materials, no construction waste is generated

during the production process, and carbon emissions are 40% lower

than those of traditional buildings. Discarded components can be

directly remelted and remade, truly achieving a "zero waste" life

cycle. Comply with international green building certification

standards and contribute to the sustainable development goals.

6. Super weather resistance, safe and reliable

It has passed the national-level seismic test (resistant to an

8-magnitude earthquake), wind pressure test (resistant to A

12-magnitude hurricane), and fire protection grade certification

(A-level non-combustible). The surface is coated with a

double-layer anti-corrosion coating, which has a weather resistance

of over 30 years. It is suitable for extreme environments such as

extreme cold, high temperature and high humidity, ensuring

long-term safe use.

7. Extra-long service life, economical and durable

Made of zinc-aluminum-magnesium coated steel, its corrosion

resistance is enhanced by three times and its design life exceeds

50 years. The maintenance-free structure design requires only

regular simple cleaning, and the overall usage cost is low.

Compared with traditional buildings, the later maintenance cost is

reduced by 70%, and the long-term economic benefits are remarkable.

8. Super large span, free space

The patented truss structure design enables a maximum single span

of 36 meters and eliminates the need for internal columns,

achieving a truly "column-free space". It is suitable for large

exhibition halls, sports venues, factory workshops and other

scenarios with strict space requirements, significantly improving

space utilization and flexibility.

FAQ

Q. Do you offer designing service for us?

A:Yes, we could design full solution drawings as your requirements.

They use software such as Auto CAD, PKPM, MTS, 3D3S, etc. we will

be glad to establish sincere business cooperation with you in the

near future

Q. What is the delivery time?

A: 30-60 days after the deposit received based on order qty and

stock

Q. How can you get a quotation for your projects?

A: You can just fill out our questionaire and send back to us. We

will get back to you soon

|