| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Nickel Alloy Pipes |

|---|---|

| Brand Name: | DINGSCO |

| Model Number: | According to customers' requirements |

| Certification: | ISO 9001:2015,PED 2014/68/EU,API 6A,API-20B,TSG,NORSOK |

| Place of Origin: | China |

| MOQ: | Negotiable |

| Price: | Negotiable |

| Payment Terms: | T/T |

| Supply Ability: | Negotiable |

| Delivery Time: | (Sample order) 7 days |

| Packaging Details: | According to customers' requests |

| Product Name: | Seamless Pipe Inconel 625 |

| Dimensions: | Customizable |

| Color: | Bright / Black |

| Surface: | As per your demands |

| Material: | Nickel Alloy |

| Feature: | Seamless Pipe / Welded Pipe |

| Company Info. |

| Hunan Dinghan New Material Technology Co., LTD |

| Verified Supplier |

| View Contact Details |

| Product List |

Seamless Pipe Inconel 625 W.Nr. 2.4856 Solution Propeller Blades Exhaust Pipes Fasteners

1. As a leading supplier and manufacturer in China, DINGSCO

provides cost-effective Inconel 625 products.

2. Inconel 625 (UNS N06625 / W.Nr. 2.4856) is a solid solution

alloy with high strength and excellent corrosion resistance. It can

be used at room temperature or at temperatures as high as 1800°F

(982°C).

3. Inconel 625 adds molybdenum and niobium elements to Inconel 600.

Both of these elements are excellent solid solution strengthening

elements. They give Inconel 625 higher strength than similar

alloys. In addition, molybdenum is very resistant to reductive

corrosion. It also gives the alloy better resistance to severe

corrosion.

4. Due to its excellent corrosion resistance, a typical application

of Inconel 625 is marine. Its resistance to localized corrosion

(pitting and crevice corrosion), chloride ion stress corrosion, and

its excellent fatigue strength make it widely used in marine parts

such as propeller blades, exhaust pipes, and fasteners. For ambient

temperature applications, Inconel 625 is recommended to be

delivered annealed.

5. In addition, Inconel 625 is also widely used in the aerospace field, thanks to its excellent high-temperature tensile properties and creep strength. Through processing and welding, Inconel 625 can be used in components such as aircraft piping systems, engine exhaust systems, fuel and hydraulic lines, and heat exchanger tubes.

6. The high temperature properties of Inconel 625 alloy also make it used in heat treatment equipment and chemical industry. Different from normal temperature applications, in high temperature applications, Inconel 625 is generally delivered as solution annealed.

7.Inconel 625 Standards

| AWS A5.11 ENiCrMo-3 | Welding Electrode |

| AWS A5.14 ERNiCrMo-3 | Filler Metal |

| ASTM B443 | Plate, Sheet and Strip |

| ASTM B564 | Forgings |

| ASTM B446 | Rod and Bar |

| ASTM B366 | Welded Fittings |

| ASTM B751 | Welded Tube |

| ASTM B704 | Welded Tube |

| ASTM B775 | Welded Pipe |

| ASTM B705 | Welded Pipe |

| ASTM B829 | Seamless Pipe & Tube |

| ASTM B444 | Seamless Pipe & Tube |

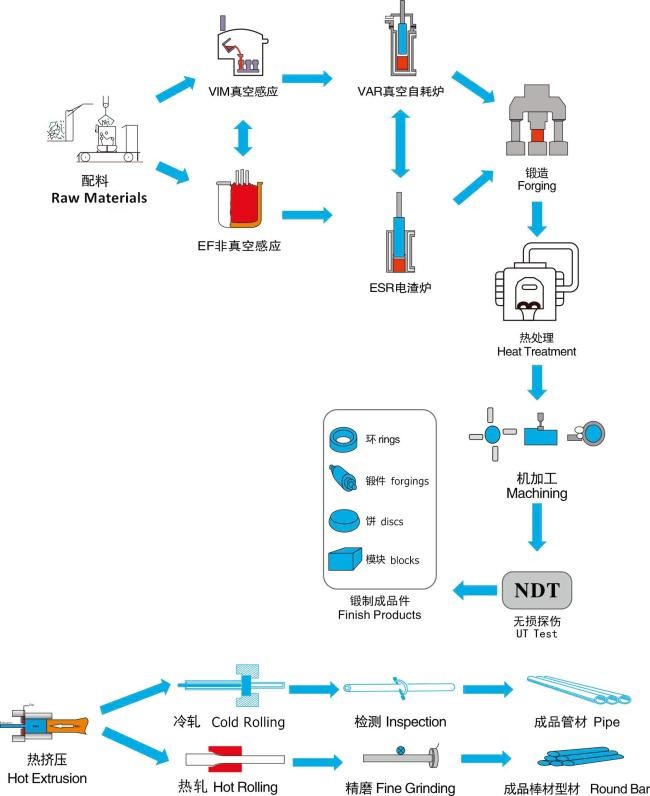

8. Progress Processing

|