| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | PE Aluminum Composite Panel |

|---|---|

| Brand Name: | richly bound |

| Model Number: | A2 Fire Rated ACP Sheets |

| Certification: | ISO 9001:2008;GB/T 17748-2016;GB 8624-2012 |

| Place of Origin: | CHINA |

| MOQ: | 1000 sqm |

| Price: | depends on your needs |

| Payment Terms: | T/T |

| Delivery Time: | usually within 14 working days |

| Packaging Details: | Stacked one by one, with fiberboard as cushion |

| Sheet thickness: | 2.0-6.0mm |

| Aluminum layer thickness: | 0.1-0.6mm |

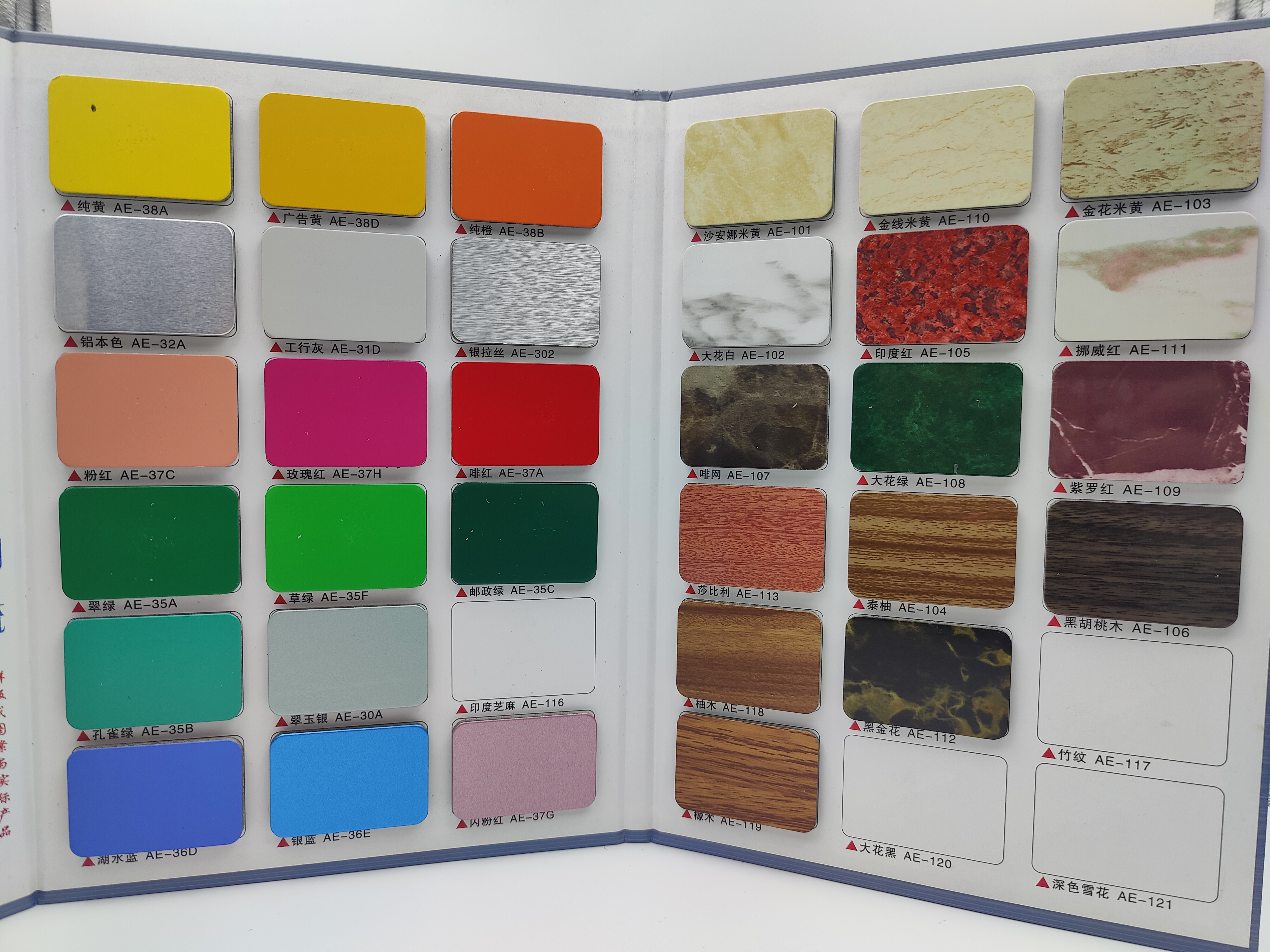

| Surface color: | Solid color,High gloss,Wood grain,Stone grain,Mirror finish,Brushed,Special effects |

| Application fields: | Exterior or Interior wall,balcony,ceilings,partitions,doors,column casings,equipment panels,interior decoration,interior design,furniture surfaces,Curtain walls,billboards,exhibitions,signs,signboard doors,coffee shop interior design |

| Surface coating: | Polyester (PE),High-performance polyester (HDPE),Fluorocarbon (PVDF),PVC film,Anodized |

| Size: | 1220mm * 2440mm,4ft * 8ft |

| Company Info. |

| Foshan Nanhai Huashi Decoration Material Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

PE Aluminum Composite Panel , 0.15 mm Aluminum , Wood Grain ,

4ft*8ft Size

What's aluminum compsite panel?

An Aluminum Plastic Panel, also known as an Aluminum Composite

Panel (ACP), is a type of composite material consisting of two thin

layers of aluminum bonded to a non-aluminum core, typically made of

polyethylene or a fire-resistant material. This structure gives the

panel a combination of lightweight properties, high strength,

weather resistance, and ease of processing, making it widely used

in exterior building cladding, interior decoration, signage, and

exhibition displays.

An Aluminum Plastic Panel, also known as an Aluminum Composite

Panel (ACP), is a type of composite material consisting of two thin

layers of aluminum bonded to a non-aluminum core, typically made of

polyethylene or a fire-resistant material. This structure gives the

panel a combination of lightweight properties, high strength,

weather resistance, and ease of processing, making it widely used

in exterior building cladding, interior decoration, signage, and

exhibition displays.

The surface of an aluminum plastic panel is often coated to enhance

its corrosion resistance and aesthetic appeal, with common coatings

including Polyester (PE) and Fluorocarbon (PVDF). The panels come

in a variety of colors and patterns, including wood grain and stone

effects, to meet different design requirements. Due to its

excellent cost-effectiveness and versatility, aluminum plastic

panel has become a popular choice in modern construction and

decoration.

Our company—— Foshan Nanhai Huashi Decoration Material Ltd.

Foshan Nanhai Huashi Decoration Material Ltd.

Since 1999, our firm has integrated both local and global

continuous extrusion hot composite sheet tech. With years of

advanced production know-how and operational expertise, we boast a

skilled team, mastering high-quality Aluminum Composite Panel

production. These panels are popular in diverse applications, from

external wall decoration to adornments like machinery casings. Our

quality commitment results in products known for durability,

aesthetics, and functionality, making them a favorite in

contemporary decoration. Taking global standards seriously, we're

proud of our ISO 9001:2008 certification and other accolades like

"China Famous Quality Product". Collaborating with research units

and industry bodies, we value your support. With our brand "Richly

Bound", we produce an array of decorative boards. Our panels meet

national standards, and our production capabilities are unmatched.

Positioned near Hong Kong and Macao, we're accessible and invite

global clients for collaborations.

Since 1999, our firm has integrated both local and global

continuous extrusion hot composite sheet tech. With years of

advanced production know-how and operational expertise, we boast a

skilled team, mastering high-quality Aluminum Composite Panel

production. These panels are popular in diverse applications, from

external wall decoration to adornments like machinery casings. Our

quality commitment results in products known for durability,

aesthetics, and functionality, making them a favorite in

contemporary decoration. Taking global standards seriously, we're

proud of our ISO 9001:2008 certification and other accolades like

"China Famous Quality Product". Collaborating with research units

and industry bodies, we value your support. With our brand "Richly

Bound", we produce an array of decorative boards. Our panels meet

national standards, and our production capabilities are unmatched.

Positioned near Hong Kong and Macao, we're accessible and invite

global clients for collaborations.

What you can purchase

Here, you can purchase a wide variety of aluminum composite panels.

We offer 4mm thick PVDF-coated panels for exterior wall decoration,

3mm thick PE wood grain-coated panels for interior decoration, 4mm

thick A2 fire-resistant panels for interior passage wall

decoration, and more. We can even customize the product's

performance based on your specific needs.

We also offer a variety of colors for you to choose:

Why is ACP?

Aluminum composite panels (ACP) offer several advantages:

Lightweight and Durable: Despite being lightweight, ACPs are strong and durable, making them ideal for both interior and exterior applications.

Versatile Design Options: They come in a wide range of colors, finishes, and textures, including options that mimic natural materials like wood or stone, allowing for versatile design possibilities.

Weather Resistance: ACPs are highly resistant to weather elements, including UV rays, moisture, and temperature fluctuations, which helps maintain their appearance and integrity over time.

Fire Resistance: High-quality ACPs, especially those with fire-retardant cores, offer excellent fire resistance, enhancing the safety of buildings.

Easy Installation and Maintenance: The panels are easy to install and require minimal maintenance, reducing overall project costs and effort.

Cost-Effective: Compared to other cladding materials, ACPs are relatively cost-effective, offering good value for their durability and aesthetic appeal.

Sound and Heat Insulation: ACPs provide good insulation against sound and heat, contributing to the energy efficiency and comfort of buildings.

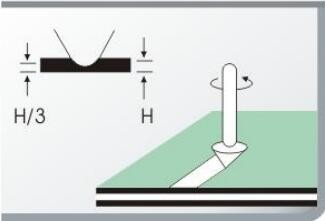

Product processing performance

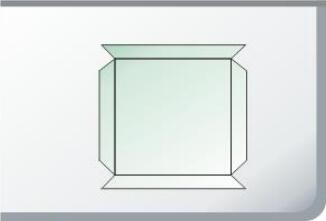

The aluminum composite panels we produce are amenable to standard woodworking and metalworking tools, enabling processes like slicing, sawing, shaping, hole-making, pressing, creasing, and curving. Such capabilities ensure precision in realizing the design specifications in architectural ornamentation, notably for configurations like bends, reverse bends, tight-cornered edges, and both inside and outside angles. Such flexibility is seldom found in other ornamental materials.

1.Sectioning: Devices include manual, powered, and circular saws.

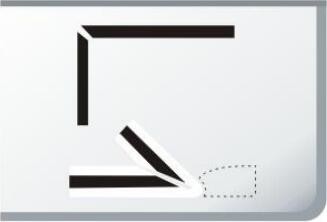

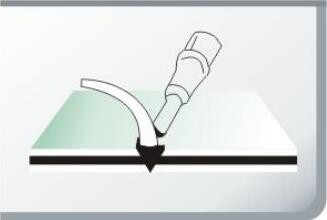

2.Channel Milling: With a handheld electric milling device,

hand-curving into multiple polyhedrons is doable.

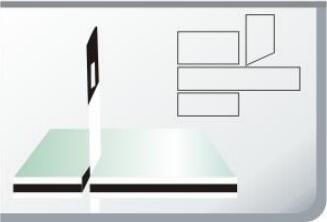

3.Edge Deduction: Following operations with punching and edge

deduction devices, assembly in structures is possible.

4.Joining: Use of plastic welding rods and hot air devices allows

for merging.

5.Edge Curve: After milling operations, varied angular shapes can

be crafted.

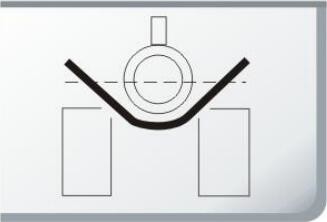

6.Arcing: Employing 3-anchor or 3-cylinder apparatuses ensures

effective curving.

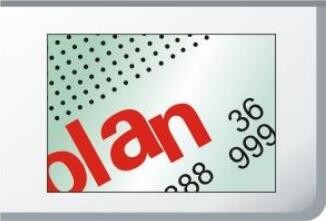

7.Imprinting: Silkscreen printing methods apply to these panels.

8.Coupling: Methods comprise of rivets, tacks, and self-drilling

screws.

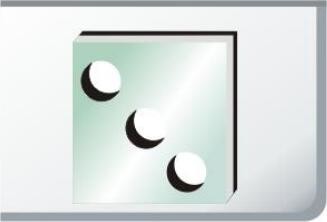

9.Perforating: Hole-making is made possible with an unrestricted

puncher.

print corner bending corner cutting welding

corpping punching bending milling groove

combination

Our production line

|