| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Auto Parts Mould |

|---|---|

| Brand Name: | Liushi |

| Model Number: | Hydrogen Energy Motor Housing |

| Certification: | ISO 9001:2008 |

| Place of Origin: | China Luoyang |

| MOQ: | 1 Piece |

| Payment Terms: | T/T |

| Delivery Time: | 30-45 days |

| Packaging Details: | Wooden Boxes |

| Product Name: | Hydrogen Energy Motor Housing |

| Mold Material: | EPS |

| Surface Treatment: | Heat Treatment |

| Customized: | Yes |

| Demoulding: | Automatic |

| Average Wall Thickness: | >3mm |

| Mould Life: | 50,000-100,000 Shots |

| Product Material: | Aluminium |

| Other name: | HICE |

| Tolerance: | Auto spare Parts |

| Company Info. |

| LUOYANG LIUSHI MOULD CO.,LTD |

| Verified Supplier |

| View Contact Details |

| Product List |

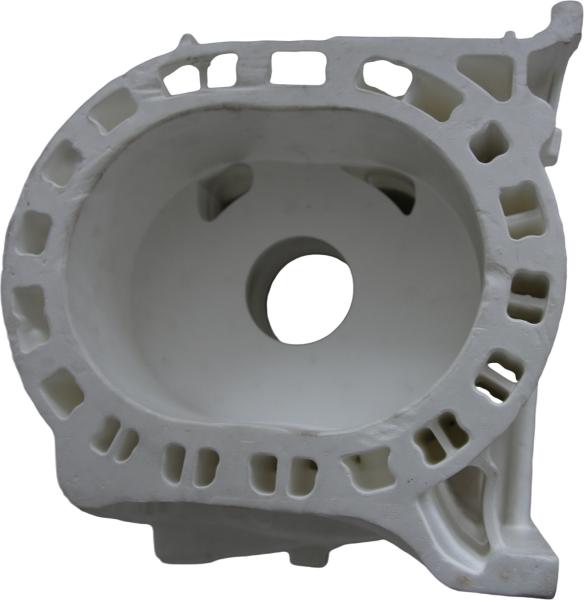

Hydrogen Energy Motor Housing HICE Auto Parts Mould

For a hydrogen fuel cell or hydrogen internal combustion engine (HICE), a hydrogen energy motor housing is a specialized part that encloses and shields the engine or motor system, guaranteeing its longevity, security, and effectiveness. The special needs of hydrogen energy systems, which are not like those of conventional gasoline or electric motors, must be met by this housing.

Auto Parts Mould Features

Product Name | Hydrogen Energy Motor Housing HICE Auto Parts Mould | ||

Size | customized | ||

Color | As your requirements | ||

Material | Aluminum | ||

Application | Auto parts, ,Light fixture, lamp cover, led light housing,heat sink

or any other type of die casting parts | ||

Service | OEM/ODM | ||

Product's Design | Customized as customers' drawings or samples | ||

Manufacture Process

1. Review the part design,drawings and quality standard from

clients.

2. Mould and Tooling design & manufacturing

3. Mould and Tooling testing & confirm the sample

4. Die casting raw castings

5. Surface treatment: Trimming,Deburring, polishing, cleaning,

passivation & power coating and other requirement from Customer

6. Precision machining: CNC lathes, milling, drilling, grinding etc

7. Full Inspection

8. Packing

9. Delivery

Our Advantages

1. We are the biggest lost foam mould manufacturer in China, we

focus on high challenge lost foam mould and we have large gantry

machining centers,30 sets imported high speed machining center,more

than 40 sets general machine tool equipment;

2. We have 36 senior mould designers, to ensure reasonable / safety

/ high efficiency mould design and ensure the fast mould delivery

and rational mould structure, make the process more safer and the

production efficiency more higher;

3. We using numerical control machine tool to manufacture the mould

cavities, to ensure a even thickness ;

4. We using ZL104 Aluminium to casting the mould, to manufacture a

high strength mould;

5. For the big mould, we using Ø22*1 copper tube as cooling pipe,

with water spray system, to get a nice cooling effect;

6. We Have (TEF10N) coating on the mould surface, it can reduce the

friction, anti water/static electricity/acid-base/high-temperature,

with this we can ensure the pattern has smooth surface without

distrotion, and easy to demould;

7. All the screws we using stainless steel screw, easy to

disassemble during maintenance;

8. For the big mould chest, we using 18-20mm thick wrought

aluminium plate, to offer high strenght cavity ;

9. For the complex mould which is difficult to demould, we can

manufacture the automaitc mould with take out device ;

10. We produce the pattern sample to customer after finish the

mould, when the pattern was qualified, then we do exceptance job

for the mould ;

11. We have the Hexagon coordinate measuring instrument imported

from the Switzerland to have a test make sure our mould qualified.

|