| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Extruded Aluminum Profiles |

|---|---|

| Brand Name: | DELLOK Yonghui |

| Model Number: | Aluminum profile |

| Certification: | CE |

| Place of Origin: | China |

| MOQ: | 1 meter |

| Price: | $10 - 1000 /Piece/Pieces |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability: | TBD |

| Delivery Time: | 1-3weeks |

| Packaging Details: | Wooden Case |

| Thickness: | Customized |

| Coil Size: | Customized |

| Length: | Customized |

| Performance: | Corrosion resistant and easy to process |

| Tube Wall Thickness: | 0.8mm |

| Outer Diameter: | Customized |

| Tube Type: | Smooth, Grooved |

| Surface Treatment: | Bare, Coated |

| Range Of Applications: | Wide |

| Antioxidant: | Strong |

| Tube Diameter: | 8mm, 10mm, 12mm |

| Tolerance: | 0.001 |

| Corrosion Resistant: | Strong |

| Working Pressure: | 0.3-2.5Mpa |

| Tube Length: | 1m, 2m, 3m |

| Company Info. |

| Dellok Yonghui Radiating Pipe Manufacturing Co.,Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

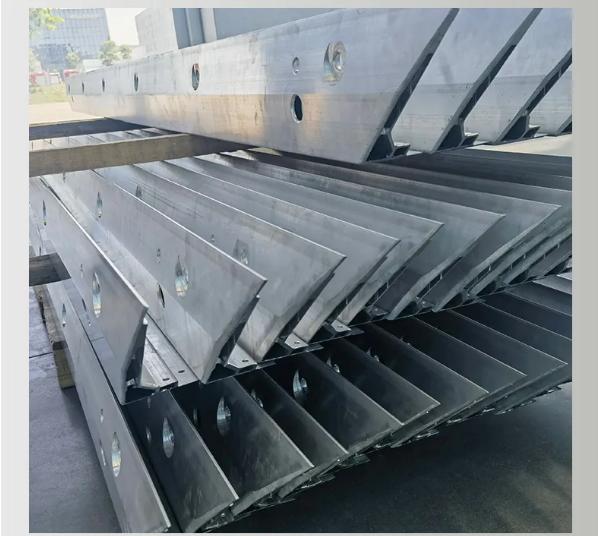

DELLOK YONGHUI Reliable delivery and timely factory direct supply of industrial aluminum profiles

FAQ

1. How are aluminum profiles finished?

Aluminum profiles can be finished in various ways to enhance their appearance, durability, and functionality, including:

Anodizing: An electrochemical process that creates a protective

oxide layer, available in different colors.

Powder Coating: A durable finish applied as a dry powder and baked

onto the surface, offering a wide range of colors and textures.

Mill Finish: The natural, uncoated surface of the aluminum, often

used for further processing or where a raw look is desired.

Polishing & Brushing: To achieve a smooth, shiny, or textured

appearance.

2. Can aluminum profiles be customized?

Yes, aluminum profiles can be highly customized to meet specific requirements. This includes custom shapes, sizes, alloys, finishes, and even integrated features like holes, slots, and threading. Custom extrusion dies are designed and manufactured to produce unique profiles tailored to the application.

3. How do I select the right aluminum profile for my project?

Selecting the right aluminum profile involves considering factors such as:

Load Requirements: Determining the necessary strength and stiffness

based on the intended use.

Environmental Conditions: Choosing an alloy and finish that can

withstand the operating environment.

Cost & Availability: Balancing material costs, processing

requirements, and availability.

Design Considerations: Ensuring the profile fits within the overall

design aesthetic and functionality.

Consulting with aluminum profile suppliers or engineers can help

guide the selection process and ensure the best fit for your

project.

|