| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Titanium Ball Valve |

|---|---|

| Brand Name: | LHTi |

| Model Number: | Titanium Ball Valve Gr1 Gr2 |

| Certification: | ISO9001,CE,etc |

| Place of Origin: | BaoJi Shaanxi China |

| MOQ: | 1 |

| Price: | negotiable |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union |

| Supply Ability: | 5 tons per month |

| Delivery Time: | 15-20 working days |

| Packaging Details: | Plywood case or pallet, or as per your requirement |

| Cavity Pressure Relief: | Yes |

| End Connections: | Flanged (ANSI, JIS, DIN, GB) |

| Testing Standards: | JB/T9092、GB/T13927、API6D、API598 |

| Fire Safe Design: | API 607, API 6FA |

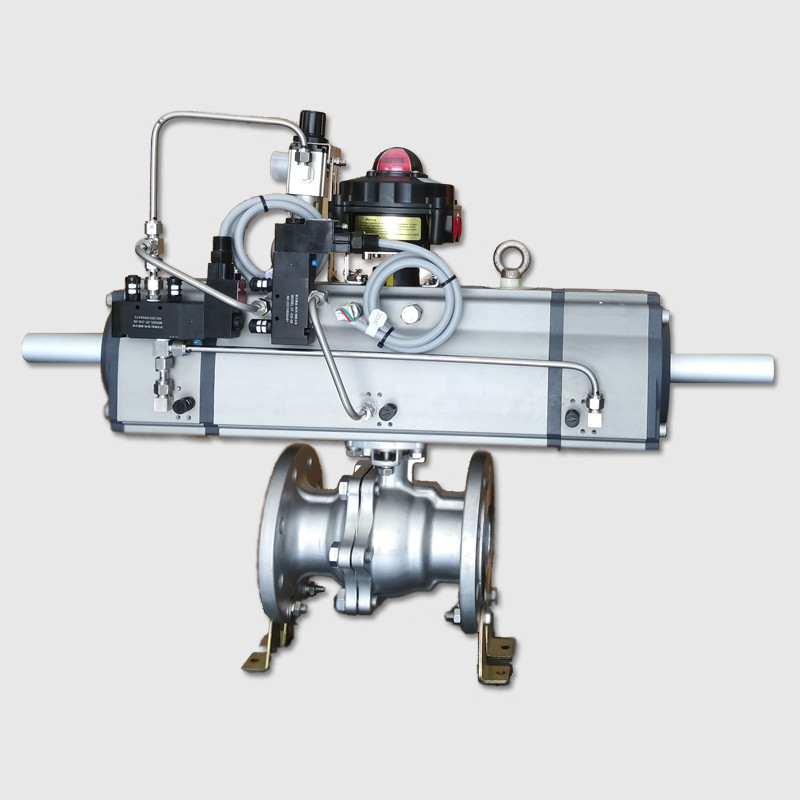

| Actuator Type: | Manual, Pneumatic, Electric |

| Body Type: | One-piece, Two-piece, Three-piece |

| Ball Material: | Titanium, Stainless Steel |

| Face To Face: | ASME B16.10 |

| Type: | Ball Valve |

| Material: | Titanium |

| Port Type: | Full Port, Reduced Port |

| Grades: | TA1 TA2 TA10 Gr2 Gr3 |

| Fire Safe: | Yes |

| Temperature Range: | -196°C to 600°C |

| Ball Materials: | Titanium TA1、TA2、TA10、Gr2、Gr3 |

| Company Info. |

| Baoji Lihua Nonferrous Metals Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

Electric Flanged Ball Valve

Product Introduction:

The Electric Flanged Ball Valve is designed for precise control and reliable performance in various industrial applications. Key features include:

This valve is ideal for use in chemical processing, water treatment, and HVAC systems, where precision and durability are crucial.

| 150# | 300# | 600# | 900# | 1500# | 2500# | |||

| NPS (inch) | Long Pattern | Short Pattern | Long Pattern | Short Pattern | Long Pattern | Long Pattern | Long Pattern | Long Pattern |

| 1/2 | 108 | 108 | 140 | 140 | 165 | |||

| 3/4 | 117 | 117 | 152 | 152 | 190 | 254 | ||

| 1 | 127 | 127 | 165 | 165 | 216 | 279 | ||

| 1.1/4 | 140 | 140 | 178 | 178 | 229 | 305 | ||

| 1.1/2 | 165 | 165 | 190 | 190 | 241 | 368 | 368 | 451 |

| 2 | 178 | 178 | 216 | 216 | 292 | 419 | 419 | 508 |

| 2.1/2 | 190 | 190 | 241 | 241 | 330 | 381 | 470 | 578 |

| 3 | 203 | 203 | 282 | 282 | 356 | 457 | 546 | 673 |

| 4 | 229 | 229 | 305 | 305 | 432 | |||

5 | 610 | 705 | 914 | |||||

6 | 394 | 267 | 403 | 403 | 559 | 737 | 832 | 1022 |

8 | 457 | 292 | 502 | 419 | 660 | 838 | 991 | 1270 |

10 | 533 | 330 | 568 | 457 | 787 | 965 | 1130 | 1422 |

12 | 610 | 356 | 648 | 502 | 838 | 1029 | 1257 | |

14 | 686 | 381 | 762 | 572 | 889 | 1130 | 1384 | |

16 | 762 | 406 | 838 | 610 | 991 | 1219 | ||

18 | 864 | 914 | 660 | 1092 | 1321 | |||

20 | 914 | 991 | 711 | 1194 | ||||

22 | 1092 | 1295 | 1549 | |||||

24 | 1067 | 1143 | 813 | 1397 | ||||

Applications of Three-Way Titanium Ball Valves:

Three-way titanium ball valves find diverse applications across various industrial sectors due to their unique properties:

Food and Pharmaceutical Industries: Titanium's non-toxic nature and lack of contamination make these valves a preferred choice for fluid control in food processing and pharmaceutical applications.

Chemical Industry: With titanium's excellent corrosion resistance, these valves are ideal for managing corrosive substances such as acids, alkalis, and oxides in chemical production processes.

Aerospace Field: Thanks to their lightweight and high-strength characteristics, three-way titanium ball valves are widely used in aerospace hydraulic and fuel systems, meeting the demanding requirements of aircraft.

Petroleum and Natural Gas Industry: They are essential in controlling the flow and pressure of fluids during the extraction, transportation, and processing of petroleum and natural gas, ensuring system safety and stability.

Marine Engineering: Their resistance to seawater corrosion makes them suitable for marine applications, including fluid control systems in subsea pipelines and offshore platforms.

Common Connection Methods for Titanium Ball Valves:

Flange Connection: Ideal for medium to high-pressure systems, this method employs flanges and bolts to firmly attach the valve to the pipeline. It offers strong sealing, and reliability, and simplifies disassembly for maintenance.

Quick-Connect Couplings: These allow for rapid assembly and disassembly, making them suitable for applications with frequent installation and removal needs, though they are generally used for low-pressure systems.

Welded Connection: Available as butt-welded or socket-welded, this method is suitable for high-temperature, high-pressure, and corrosive media applications. It provides a permanent, leak-proof connection, ensuring maximum sealing and stability.

|