| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Mixing Elements |

|---|---|

| Brand Name: | Nanxiang |

| Model Number: | 56 |

| Certification: | ISO9001 2015 |

| Place of Origin: | China |

| MOQ: | Negotiable |

| Price: | Negotiable |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 300m/Month |

| Delivery Time: | 30~60 days |

| Packaging Details: | Wooden case Sea-worthy or export standard |

| Product name: | Toothed Mixing Elements TME |

| Model: | φ20mm ~ φ350mm |

| Material: | 38CrMoALA/ W6Mo5Cr4V2/ HIP |

| Properties: | Wear-resisting, Corrode-resisting, Durable |

| Application: | Twin screw Extruder |

| Packing: | Wooden Box Packing |

| Connection method: | Spline |

| Heat treatment: | Vacuum hardening |

| Company Info. |

| Chengdu Nanxiang Qiaolin Machinery Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

PM HIP TME Material Mixing Screw Elements for Double Extruders in Petrochemical Factory

Product Description

TME is a toothed disc screw element, usually used in the melting

and kneading section of the material. The TME have two types, the

forward teeth and the reverse teeth, which can be paired with one

forward and one reverse teeth. It is also available to use in

series with two or three forward discs. The staggered tooth shape

can divert and plasticize the material, but the conveying capacity

is weak. The toothed mixing elements are conducive to dispersion

and distributed mixing, and the energy consumption is normal. There

can be multiple combinations of component selection, which can be

continuously optimized during the implementation-correction

reimplementation and re-correction process.

We can satisfy your different material needs: According to

appearance design.

Specification

| Screw Diameter | 85mm |  |

| Screw Design | Toothed Mixing Elements TME | |

| Hardness | 58-60HRC | |

| Brand Name | Nanxiang | |

| Surface Treatment | Polishing/Sand Blasting | |

| Materials | SAM10/SAM39/WR5/WR14/W6Mo5Cr4V2 | |

| Place of Origin | Sichuan , China | |

| Warranty | 1 Years | |

| Screw Range | Φ 15.6 - Φ 430mm | |

| Suit For | Pharmaceuticals Extrusion Chemical Extrusion Food Extrusion Powder Coating Extrusion | |

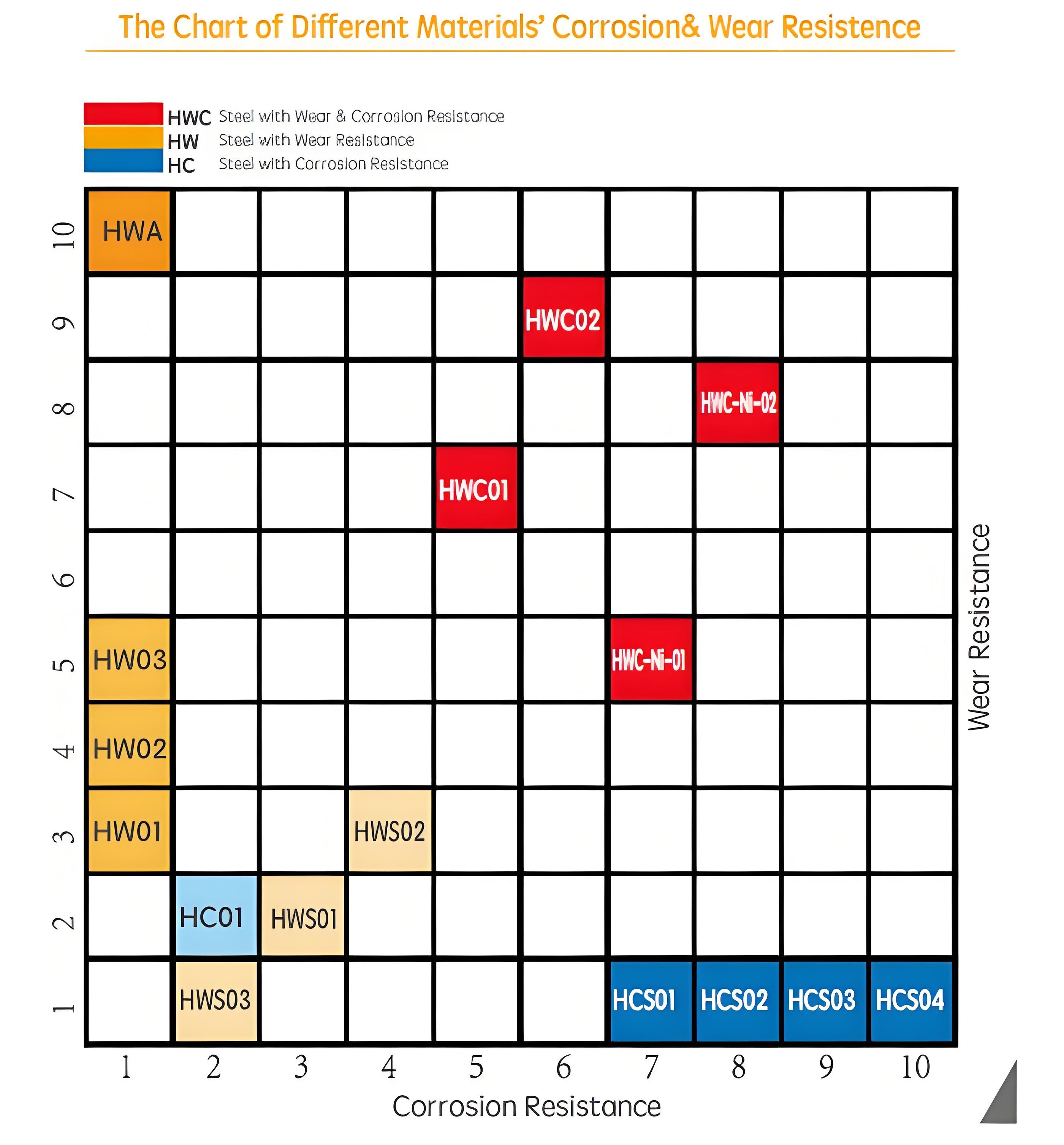

Extruder Screw Materials

1. For wear application:

Tool Steel : W6Mo5Cr4V2;

PM-HIP material : SAM10 SAM26 SAM39 CPM10V CPM9V

2. For corrosion application:

Nitrided Steel: 38CrMoAI;

PM-HIP material : SAM26 SAM39 CPM10V CPM9V

3. For wear and corrosion application:

PM-HIP material:SAM26 SAM39 CPM10V CPM9V

4. Other Materials:

Stainless Steel: 316L, C276, SX737 etc.

Co-rotating twin screw elements for

| W&P: ZSK-MC | Berstorff: ZE |

| Leistritz: ZSE-MICRO | Theysohn: TSK |

| Maris:TM-W | APV: MP65 |

| JSW: TEX | SM: TEK-HS |

| Feddem: FED-MTS | Fessia Macross: NRII |

| TOSHIBA: TEM | USEON: TDS |

| Labtech: LTE | SHIZHOU: MTE |

Different types of kneading blocks are provided

30° kneading block

45° kneading block

60° kneading block

90° kneading block

3KB kneading block

Reverse 45° kneading block

Quality Control

1). Materials control: All the materials are purchased from the

domestic brands or European twin-screw specialty materials

suppliers, which tested by elemental analysis and metallurgical

inspections to ensure the quality.

2). The internal splines is checked by the spline plug to ensure

interchangeability of the elements

3). All components are machined by CNC machines to ensure the

shapes and tolerances of the elements

4). Adopt the European high-speed steel powder processing

technology, and do the treatment according to the strict heat

treatment 4 process to ensure the wear and corrosion performance

same as the foreign brands.

5). Professional technical team can not only provide timely and

accurate mapping sample design but also the combination of elements

of technical services.

6). There are various prepared technical information and the

fixtures for the various brands extruders to ensure the timely lead

time. The common components have a lot of stock, even the new one,

it can be delivered within 45days.

7). The modern management system can ensure the products 100%

qualified and tracked.

Tool Steel

| W6Mo5Cr4V2 Chemical Composition | |||||||||||

| C | SI | Mn | P | S | Cr | Mo | V | W | Cu | Ni | |

| W-% | 0.88 | 0.35 | 0.3 | 0.023 | 0.003 | 4.03 | 4.81 | 1.86 | 5.95 | 0.12 | 0.24 |

Production Process

| NO.1 |

NO.2 |  |

| NO.3 |

NO.4 |  |

| NO.5 |

NO.6 |  |

Product accuracy

There are some differences between Nanxiang Machinery and Nanjing's

production technology. Nanjing's finishing process is carried out

before heat treatment, and the deformation after heat treatment is

not controlled, making accuracy difficult to maintain. In contrast,

our finishing process at Nanxiang is conducted after heat

treatment, which eliminates any deformation that occurs during heat

treatment. This results in higher precision and allows for zero

seam connection.

Customer trust

Packing&Delivery

Packing Details: According to your order quantity packaging,

shipping wooden boxes, air carton.

Delivery Details: 20-60days after order.

FAQ

Q: Are you a trading company or a manufacturer?

A: We are a manufacturer.

Q: Where is your factory located? How can I visit there?

A: Our factory is located in Chengdu, Sichuan Province, China. You

can fly directly to Chengdu Airport, and we will pick you up upon

arrival. We warmly welcome all our clients, both domestic and

international, to visit us.

Q: How long will your product last?

A: The lifespan of our products can vary greatly depending on the

operation time, materials used, and working conditions. Therefore,

it is difficult to provide an exact duration.

|