| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Powder Coating Line |

|---|---|

| Place of Origin: | Zhejiang, China |

| Brand Name: | HUA XIANG CUN |

| Price: | $130,000.00/sets >=1 sets |

| MOQ: | 1 |

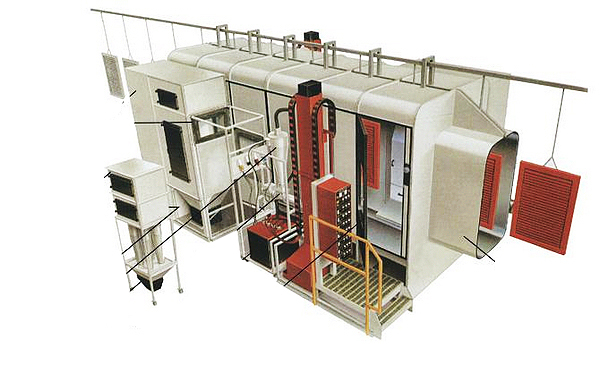

| Type: | Coating Production Line |

| Substrate: | Steel |

| Condition: | New |

| Machine Type: | powder coating line, Spray Booths, Painting Equipment, Pre-treatment Equipment, Conveying Equipment, Curing oven, Coating Equipment |

| Video outgoing-inspection: | Provided |

| Machinery Test Report: | Not Available |

| Marketing Type: | New Product 2020 |

| Warranty of core components: | 1 Year |

| Core Components: | PLC, Engine, Pressure vessel |

| Coating: | Powder Coating |

| Voltage: | 380V 50-60Hz |

| Power: | ODM |

| Dimension(L*W*H): | ODM |

| Warranty: | 12 month |

| Key Selling Points: | Easy to Operate |

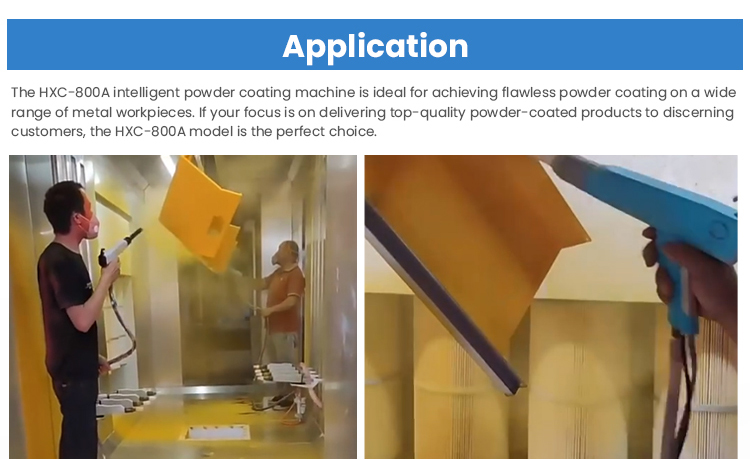

| Applicable Industries: | Manufacturing Plant, Retail, Printing Shops, Construction works |

| Showroom Location: | Egypt, Canada, Germany |

| Weight (KG): | 10000 |

| After-sales Service Provided: | Engineers available to service machinery overseas |

| Material: | 1.2mm steel |

| Insulation thickness: | 120mm |

| Insulation Material: | Rockwool |

| Company Info. |

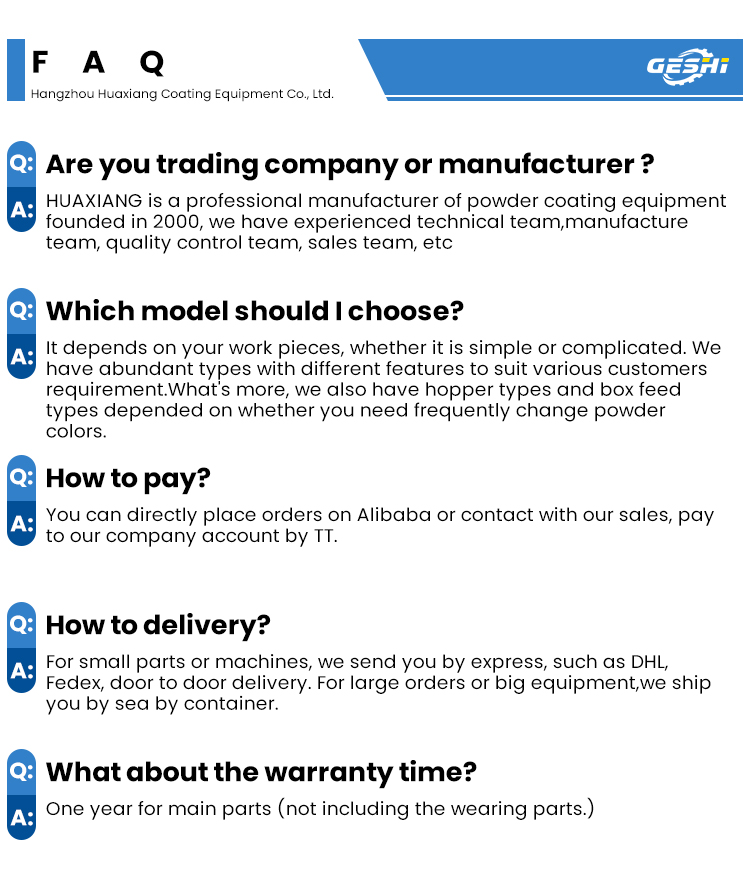

| Hangzhou Huaxiang Coating Equipment Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

item | value |

Type | Coating Production Line |

Substrate | Steel |

Condition | New |

Machine Type | powder coating line |

Video outgoing-inspection | Provided |

Machinery Test Report | Not Available |

Marketing Type | New Product 2020 |

Warranty of core components | 1 Year |

Core Components | PLC, Engine, Pressure vessel |

Coating | Powder Coating |

Place of Origin | China |

Zhejiang | |

Brand Name | HUA XIANG CUN |

Voltage | 380V 50-60Hz |

Power | ODM |

Dimension(L*W*H) | ODM |

Warranty | 12 month |

Key Selling Points | Easy to Operate |

Applicable Industries | Manufacturing Plant, Retail, Printing Shops, Construction works |

Showroom Location | Egypt, Canada, Germany |

Weight (KG) | 10000 |

Machine Type | Spray Booths, Painting Equipment, Pre-treatment Equipment,

Conveying Equipment, Curing oven, Coating Equipment |

After-sales Service Provided | Engineers available to service machinery overseas |

Material | 1.2mm steel |

Insulation thickness | 120mm |

Insulation Material | Rockwool |

|