| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Powder Coating Machine |

|---|---|

| Place of Origin: | ZHE |

| Price: | $445.00/pieces 1-10 pieces |

| MOQ: | 1 |

| Type: | Powder Coating Booth |

| Substrate: | Steel |

| Condition: | New |

| Machine Type: | powder coating spray gun, Coating Equipment |

| Video outgoing-inspection: | Provided |

| Machinery Test Report: | Provided |

| Marketing Type: | Ordinary Product |

| Warranty of core components: | 1 Year |

| Core Components: | Pump |

| Coating: | Powder Coating |

| Voltage: | 110V/220V |

| Power: | 50W |

| Dimension(L*W*H): | 35*6*22 |

| Warranty: | 1 Year |

| Key Selling Points: | Competitive Price |

| Applicable Industries: | Manufacturing Plant |

| Showroom Location: | India, Russia, Argentina, South Korea, UAE, Sri Lanka, South Africa |

| Weight (KG): | 0.48 |

| Company Info. |

| Hangzhou Huaxiang Coating Equipment Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

Preparation of Powder Coating:

Electrostatic Charging:

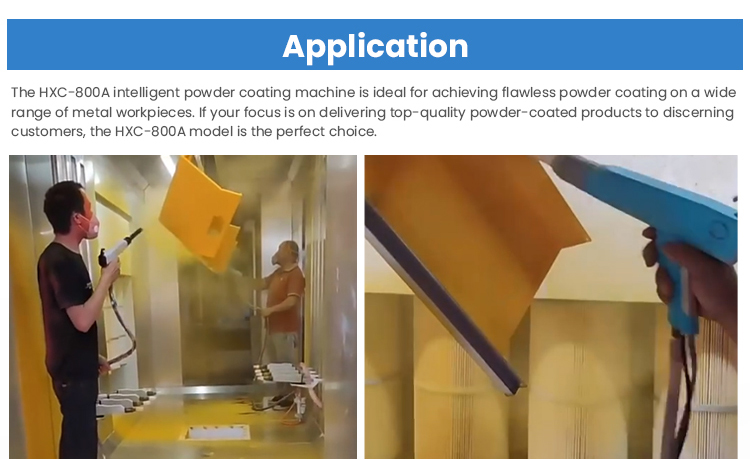

Spraying Process:

Coating Deposition:

Curing Process:

No | Item | Data |

1 | Voltage | 110v/220v |

2 | Frenquency | 50/60HZ |

3 | Input power | 50W |

4 | Max. output current | 200ua |

5 | Output power voltage | 0-100kv |

6 | Input Air pressure | 0.3-0.6Mpa |

7 | Polarity | Negative |

8 | Gun weight | 480g |

|