| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Carbon Steel Fittings |

|---|---|

| Brand Name: | Kasugai |

| Model Number: | ASTM A234 WPB B16.9 Eccentric Reducer |

| Place of Origin: | China |

| MOQ: | Negotiable |

| Price: | Negotiable |

| Payment Terms: | L / C , T / T |

| Supply Ability: | 800ton per month |

| Delivery Time: | 30 - 60 working days |

| Packaging Details: | Seaworthy Packng |

| Product Name: | ASTM A234 WPB B16.9 Eccentric Reducer |

| Size Range: | 1/2" to 48" |

| Standards: | ASTM A234 |

| Wall Thickness: | SGP STD SCH5S SCH10S SCH40S SCH 80S SCH160S XS XXS |

| Manufacturing Standards: | ASME B16.9 MSS SP-43 |

| Coating: | Rust-proof black oil or hot galvanized, Transparent oil |

| Company Info. |

| Kasugai Shanghai Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

ASTM A234 Gr. WPB ASME B16.9 Carbon Steel Eccentric Reducer

ASTM A234 WPB is the material specification for carbon steel fittings for high-temperature piping applications. This standard covers the requirements for wrought carbon steel and alloy steel fittings suitable for welding, threaded, and flanged connections.

An eccentric reducer is a type of pipe fitting used to connect two pipes of different diameters, where the center lines of the two pipes are not aligned. The eccentricity allows for a smooth transition between the different pipe sizes while maintaining an uninterrupted flow path.

ASTM A234 WPB B16.9 Eccentric Reducer

STM A234 WPB Reducer is used to connect two pipes of different size in a piping system. One end of the A234 WPB Reducer corresponds to the diameter of the large diameter pipe and the other end of the Concentric Reducer A234 corresponds to the diameter of the small diameter pipe.

Eccentric Reducer Features

1. Material: Made from ASTM A234 WPB carbon steel, which provides high strength and corrosion resistance.

2. Dimensional Standard: Manufactured to the B16.9 dimensional standard, ensuring proper fit and compatibility with other piping components.

3. Eccentric Design: The offset center lines allow for a smooth flow transition between different pipe sizes.

4. Welding: Suitable for welding connections, providing a strong and durable joint.

ASTM A234 WPB B16.9 Concentric / Eccentric Reducer Dimensions (mm)

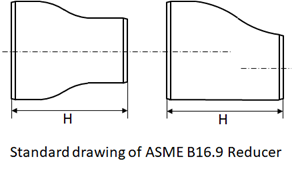

The reducers are often used when the piping designers want to reduce the diameter of a straight run of pipe. There are two styles of standard reducers available in ASME B16.9: Concentric – having a common centerline; Eccentric reducer – having offset centerlines.

| NPS | O.D L mm inch | O.D S mm inch | H mm inch |

| 3/4 x 1/2 | 26.7 1.05 | 21.3 0.84 | 38 1.50 |

| 3/4 x 3/8 | 26.7 1.05 | 17.3 0.68 | 38 1.50 |

| 1 x 3/4 | 33.4 1.32 | 26.7 1.05 | 51 2.00 |

| 1 x 1/2 | 33.4 1.32 | 21.3 0.84 | 51 2.00 |

| 1-1/4 x 1 | 42.2 1.66 | 33.4 1.32 | 51 2.00 |

| 1-1/4 x 3/4 | 42.2 1.66 | 26.7 1.05 | 51 2.00 |

| 1-1/4 x 1/2 | 42.2 1.66 | 21.3 0.84 | 51 2.00 |

| 1-1/2 x 1-1/4 | 48.3 1.90 | 42.2 1.66 | 64 2.50 |

| 1-1/2 x 1 | 48.3 1.90 | 33.4 1.32 | 64 2.50 |

| 1-1/2 x 3/4 | 48.3 1.90 | 26.7 1.05 | 64 2.50 |

| 1-1/2 x 1/2 | 48.3 1.90 | 21.3 0.84 | 64 2.50 |

| 2 x 1-1/2 | 60.3 2.38 | 48.3 1.90 | 76 3.00 |

| 2 x 1-1/4 | 60.3 2.38 | 42.2 1.66 | 76 3.00 |

| 2 x 1 | 60.3 2.38 | 33.4 1.32 | 76 3.00 |

| 2 x 3/4 | 60.3 2.38 | 26.7 1.05 | 76 3.00 |

| 2-1/2 x 2 | 73.0 2.88 | 60.3 2.38 | 89 3.50 |

| 2-1/2 x 1-1/2 | 73.0 2.88 | 48.3 1.90 | 89 3.50 |

| 2-1/2 x 1-1/4 | 73.0 2.88 | 42.2 1.66 | 89 3.50 |

| 2-1/2 x 1 | 73.0 2.88 | 33.4 1.32 | 89 3.50 |

| 3 x 2-1/2 | 88.9 3.50 | 73.0 2.88 | 89 3.50 |

| 3 x 2 | 88.9 3.50 | 60.3 2.38 | 89 3.50 |

| 3 x 1-1/2 | 88.9 3.50 | 48.3 1.90 | 89 3.50 |

| 3 x 1-1/4 | 88.9 3.50 | 42.2 1.66 | 89 3.50 |

| 3-1/2 x 3 | 101.6 4.00 | 88.9 3.50 | 102 4.00 |

| 3-1/2 x 2-1/2 | 101.6 4.00 | 73.0 2.88 | 102 4.00 |

| 3-1/2 x 2 | 101.6 4.00 | 60.3 2.38 | 102 4.00 |

| 3-1/2 x 1-1/2 | 101.6 4.00 | 48.3 1.90 | 102 4.00 |

| 3-1/2 x 1-1/4 | 101.6 4.00 | 42.2 1.66 | 102 4.00 |

| 4 x 3-1/2 | 114.3 4.50 | 101.6 4.00 | 102 4.00 |

| 4 x 3 | 114.3 4.50 | 88.9 3.50 | 102 4.00 |

| 4 x 2-1/2 | 114.3 4.50 | 73.0 2.88 | 102 4.00 |

| 4 x 2 | 114.3 4.50 | 60.3 2.38 | 102 4.00 |

| 4 x 1-1/2 | 114.3 4.50 | 48.3 1.90 | 102 4.00 |

| 5 x 4 | 141.3 5.56 | 114.3 4.50 | 127 5.00 |

| 5 x 3-1/2 | 141.3 5.56 | 101.6 4.00 | 127 5.00 |

| 5 x 3 | 141.3 5.56 | 88.9 3.50 | 127 5.00 |

| 5 x 2-1/2 | 141.3 5.56 | 73.0 2.88 | 127 5.00 |

| 5 x 2 | 141.3 5.56 | 60.3 2.38 | 127 5.00 |

| 6 x 5 | 168.3 6.62 | 141.3 5.56 | 140 5.50 |

| 6 x 4 | 168.3 6.62 | 114.3 4.50 | 140 5.50 |

| 6 x 3-1/2 | 168.3 6.62 | 101.6 4.00 | 140 5.50 |

| 6 x 3 | 168.3 6.62 | 88.9 3.50 | 140 5.50 |

| 6 x 2-1/2 | 168.3 6.62 | 73.0 2.88 | 140 5.50 |

| 8 x 6 | 219.1 8.62 | 168.3 6.62 | 152 6.00 |

| 8 x 5 | 219.1 8.62 | 141.3 5.56 | 152 6.00 |

| 8 x 4 | 219.1 8.62 | 114.3 4.50 | 152 6.00 |

| 8 x 3-1/2 | 219.1 8.62 | 101.6 4.00 | 152 6.00 |

| 10 x 8 | 273.0 10.75 | 219.1 8.62 | 178 7.00 |

| 10 x 6 | 273.0 10.75 | 168.3 6.62 | 178 7.00 |

| 10 x 5 | 273.0 10.75 | 141.3 5.56 | 178 7.00 |

| 10 x 4 | 273.0 10.75 | 114.3 4.50 | 178 7.00 |

| 12 x 10 | 323.8 12.75 | 273.0 10.75 | 203 8.00 |

| 12 x 8 | 323.8 12.75 | 219.1 8.62 | 203 8.00 |

| 12 x 6 | 323.8 12.75 | 168.3 6.62 | 203 8.00 |

| 12 x 5 | 323.8 12.75 | 141.3 5.56 | 203 8.00 |

| 14 x 12 | 355.6 14.00 | 323.8 12.75 | 330 13.00 |

| 14 x 10 | 355.6 14.00 | 273.0 10.75 | 330 13.00 |

| 14 x 8 | 355.6 14.00 | 219.1 8.62 | 330 13.00 |

| 14 x 6 | 355.6 14.00 | 168.3 6.62 | 330 13.00 |

| 16 x 14 | 406.4 16.00 | 355.6 14.00 | 356 14.00 |

| 16 x 12 | 406.4 16.00 | 323.8 12.75 | 356 14.00 |

| 16 x 10 | 406.4 16.00 | 273.0 10.75 | 356 14.00 |

| 16 x 8 | 406.4 16.00 | 219.1 8.62 | 356 14.00 |

| 18 x 16 | 457 18.00 | 406.4 16.00 | 381 15.00 |

| 18 x 14 | 457 18.00 | 355.6 14.00 | 381 15.00 |

| 18 x 12 | 457 18.00 | 323.8 12.75 | 381 15.00 |

| 18 x 10 | 457 18.00 | 273.0 10.75 | 381 15.00 |

| 20 x 18 | 508 20.00 | 457 18.00 | 508 20.00 |

| 20 x 16 | 508 20.00 | 406.4 16.00 | 508 20.00 |

| 20 x 14 | 508 20.00 | 355.6 14.00 | 508 20.00 |

| 20 x 12 | 508 20.00 | 323.8 12.75 | 508 20.00 |

| 22 x 20 | 559 22.00 | 508 20.00 | 508 20.00 |

| 22 x 18 | 559 22.00 | 457 18.00 | 508 20.00 |

| 22 x 16 | 559 22.00 | 406.4 16.00 | 508 20.00 |

| 22 x 14 | 559 22.00 | 355.6 14.00 | 508 20.00 |

| 24 x 22 | 610 24.00 | 559 22.00 | 508 20.00 |

| 24 x 20 | 610 24.00 | 508 20.00 | 508 20.00 |

| 24 x 18 | 610 24.00 | 457 18.00 | 508 20.00 |

| 24 x 16 | 610 24.00 | 406.4 16.00 | 508 20.00 |

| 26 x 24 | 660 26.00 | 610 24.00 | 610 24.00 |

| 26 x 22 | 660 26.00 | 559 22.00 | 610 24.00 |

| 26 x 20 | 660 26.00 | 508 20.00 | 610 24.00 |

| 26 x 18 | 660 26.00 | 457 18.00 | 610 24.00 |

| 28 x 26 | 711 28.00 | 660 26.00 | 610 24.00 |

| 28 x 24 | 711 28.00 | 610 24.00 | 610 24.00 |

| 28 x 20 | 711 28.00 | 508 20.00 | 610 24.00 |

| 28 x 18 | 711 28.00 | 457 18.00 | 610 24.00 |

| 30 x 28 | 762 30.00 | 711 28.00 | 610 24.00 |

| 30 x 26 | 762 30.00 | 660 26.00 | 610 24.00 |

| 30 x 24 | 762 30.00 | 610 24.00 | 610 24.00 |

| 30 x 20 | 762 30.00 | 508 20.00 | 610 24.00 |

| 32 x 30 | 813 32.00 | 762 30.00 | 610 24.00 |

| 32 x 28 | 813 32.00 | 711 28.00 | 610 24.00 |

| 32 x 26 | 813 32.00 | 660 26.00 | 610 24.00 |

| 32 x 24 | 813 32.00 | 610 24.00 | 610 24.00 |

| 34 x 32 | 864 34.00 | 813 32.00 | 610 24.00 |

| 34 x 30 | 864 34.00 | 762 30.00 | 610 24.00 |

| 34 x 26 | 864 34.00 | 660 26.00 | 610 24.00 |

| 34 x 24 | 864 34.00 | 610 24.00 | 610 24.00 |

| 36 x 34 | 914 36.00 | 864 34.00 | 610 24.00 |

| 36 x 32 | 914 36.00 | 813 32.00 | 610 24.00 |

| 36 x 30 | 914 36.00 | 762 30.00 | 610 24.00 |

| 36 x 26 | 914 36.00 | 660 26.00 | 610 24.00 |

| 36 x 24 | 914 36.00 | 610 24.00 | 610 24.00 |

| 38 x 36 | 965 38.00 | 914 36.00 | 610 24.00 |

| 38 x 34 | 965 38.00 | 864 34.00 | 610 24.00 |

| 38 x 32 | 965 38.00 | 813 32.00 | 610 24.00 |

| 38 x 30 | 965 38.00 | 762 30.00 | 610 24.00 |

| 38 x 28 | 965 38.00 | 711 28.00 | 610 24.00 |

| 38 x 26 | 965 38.00 | 660 26.00 | 610 24.00 |

| 40 x 38 | 1016 40.00 | 965 38.00 | 610 24.00 |

| 40 x 36 | 1016 40.00 | 914 36.00 | 610 24.00 |

| 40 x 34 | 1016 40.00 | 864 34.00 | 610 24.00 |

| 40 x 32 | 1016 40.00 | 813 32.00 | 610 24.00 |

| 40 x 30 | 1016 40.00 | 762 30.00 | 610 24.00 |

| 42 x 40 | 1067 42.00 | 1016 40.00 | 610 24.00 |

| 42 x 38 | 1067 42.00 | 965 38.00 | 610 24.00 |

| 42 x 36 | 1067 42.00 | 914 36.00 | 610 24.00 |

| 42 x 34 | 1067 42.00 | 864 34.00 | 610 24.00 |

| 42 x 32 | 1067 42.00 | 813 32.00 | 610 24.00 |

| 42 x 30 | 1067 42.00 | 711 28.00 | 610 24.00 |

| 44 x 42 | 1118 44.00 | 1067 42.00 | 610 24.00 |

| 44 x 40 | 1118 44.00 | 1016 40.00 | 610 24.00 |

| 44 x 38 | 1118 44.00 | 965 38.00 | 610 24.00 |

| 44 x 36 | 1118 44.00 | 914 36.00 | 610 24.00 |

| 46 x 44 | 1168 46.00 | 1118 44.00 | 711 28.00 |

| 46 x 42 | 1168 46.00 | 1067 42.00 | 711 28.00 |

| 46 x 40 | 1168 46.00 | 1016 40.00 | 711 28.00 |

| 46 x 38 | 1168 46.00 | 965 38.00 | 711 28.00 |

| 48 x 46 | 1219 48.00 | 1168 46.00 | 711 28.00 |

| 48 x 44 | 1219 48.00 | 1118 44.00 | 711 28.00 |

| 48 x 42 | 1219 48.00 | 1067 42.00 | 711 28.00 |

| 48 x 40 | 1219 48.00 | 1016 40.00 | 711 28.00 |

*NPS: Nominal Pipe Size; O.D L: Outside Diameter at Bevel, large end; O.D S: Outside Diameter at Bevel, small end; H: Center-to-End.

ASTM A234 WPB CAP Chemical Compositions (%)

| Grade | C | Mn | P | S | Si | Cr | Mo | Ni | Cu | V | Nb |

| WPB | ≤0.30 | 0.29-1.60 | ≤0.050 | ≤0.058 | ≥0.10 | ≤0.40 | ≤0.15 | ≤0.40 | ≤0.40 | ≤0.08 | 0.02 |

*For ASTM A234 Gr. WPB, the carbon equivalent (C.E.), based on heat analysis and the following formula, shall be no greater than 0.50. C.E. = C + Mn / 6 + (Cr + Mo + V) / 5 + (Ni + Cu) / 15. The C.E. values shall be reported on the test report.

*ASTM A234 WPB fittings made from bar or plate may have 0.35 max carbon and that made from forgings may have 0.35 max carbon and 0.35 max silicon with no minimum.

*For each reduction of 0.01% below the specified carbon maximum, an increase of 0.06% manganese above the specified maximum will be permitted, up to a maximum of 1.65%.

*The sum of copper, nickel, chromium, and molybdenum shall not exceed 1.00%

|