| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Automatic filling machine |

|---|---|

| Brand Name: | Tengzhuo |

| Model Number: | WFI002 |

| Certification: | CE, RoHS |

| Place of Origin: | China |

| MOQ: | one piece |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Delivery Time: | 35 working days |

| Packaging Form: | Different bottle |

| Customization: | Logo / Size / Parts Brand/ Material |

| Packaging Type: | plastic cup, paper cup, aluminum and plastic cup box products |

| Operation: | Easy Operation |

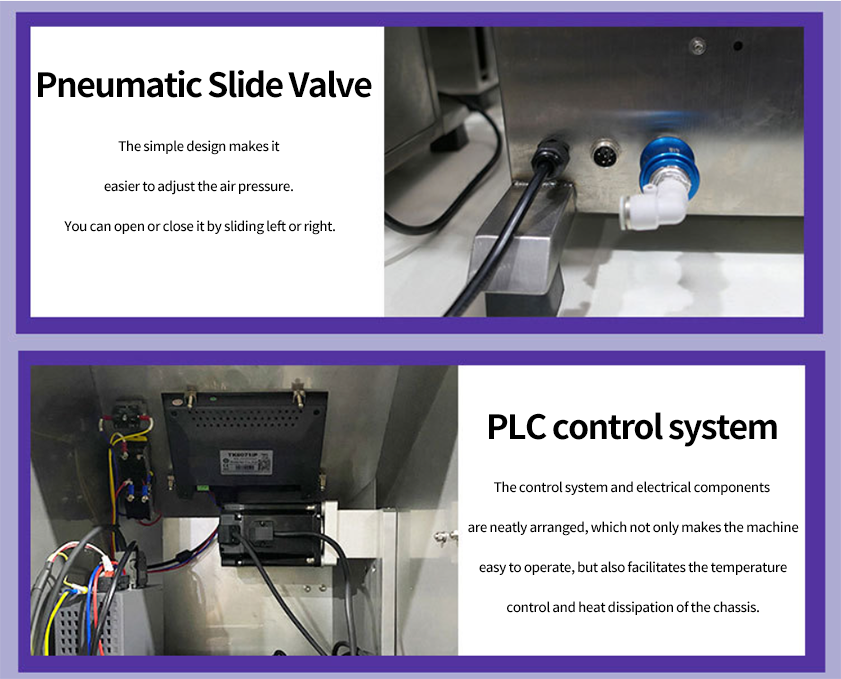

| Feature: | Automatic,PLC,Touch Screen |

| Size: | 450*450*1200 mm |

| Filling Speed: | 50-10000 ml |

| Machine weight: | 25 kg |

| Lead Time: | 30 working days |

| Market: | Brazil,Ecuador,France,USA |

| Production capacity: | 10-60 (cans/minute) |

| Machine cover: | 304# stainless steel |

| Company Info. |

| Guangzhou TENGZHUO Machinery Equipment Co,Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

A semi-automatic filling machine is a device used to dispense precise amounts of liquid, paste, or powder into containers such as bottles, jars, or pouches.

It bridges the gap between manual and fully automatic filling processes, providing increased efficiency while maintaining control over the filling process.

Here are some key features and benefits of semi-automatic filling machines:

1. Program controller: Lexar

2. Touch screen: Lexar

3. Pneumatic components: Taiwan AIRTAC/Japan SMCXingchen

4. Photoelectric sensor: Germany LEUZE or Germany SICK, Japan Panasonic

5. Relay and air switch: France Schneider, Shenle, Delixi

6. Filling range: 50ml-10000ml

7. Filling quantitative principle: rotor pump type

8 Number of filling heads: 1

9. Filling speed: 900-1000 bottles/hour (300ml/bottle)

10. Machine cover: 304# stainless steel,

11. Compatible with bottles of different shapes and specifications within a certain range. The specific requirements are to put the bottle on the machine and pass the test

12. Overall dimensions 450*450*1200 mm

13. Production capacity 10-60 (cans/minute)

14. Unit weight: 25kg

|