| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Rotary Slitter Blades |

|---|---|

| Brand Name: | Seton |

| Model Number: | TCT |

| Certification: | CE ISO |

| Place of Origin: | China |

| MOQ: | MOQ 10 Pieces |

| Price: | Can be discussed |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability: | 500 Piece/Pieces per Day |

| Delivery Time: | 30 days |

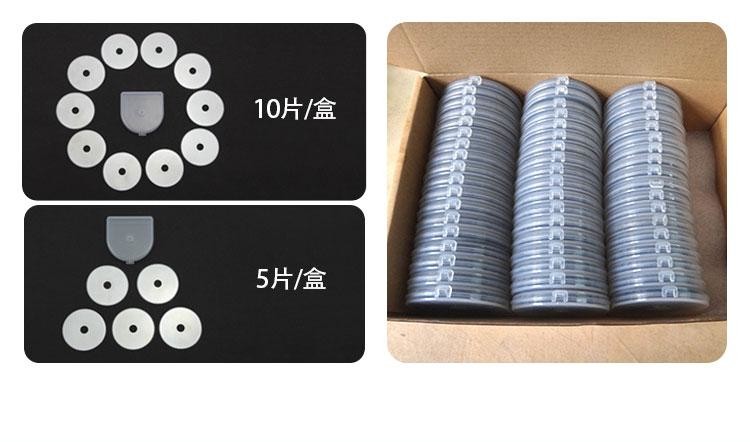

| Packaging Details: | 1pc/wrapper, 100pcs/box, 100boxes/ctn,Wooden and carbon boxes |

| Product Name: | Circular Slitting Knife Blades |

| Material: | TCT |

| Precision: | 0.01-0.03mm |

| Hardness: | HRC 45~92 |

| Outer Diameter: | 230mm |

| Thickness: | 1.1mm |

| Inner Diameter: | 110mm |

| Applicable Industries: | Manufacturing Plant |

| Company Info. |

| Jiangsu Seton Industrial Technology Co,.Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

TCT Circular Slitting Knife Blades Corrugated Box Cutting 230*110*1.1Mm

Description:

Here are the key features of TCT (Tungsten Carbide Tipped) corrugated flat circular cutting blades:

1,Exceptional Wear Resistance

2,Sharp Cutting Edge

3,Excellent Thermal Resistance

4,Reduced Noise

5,Clean Cut Edges

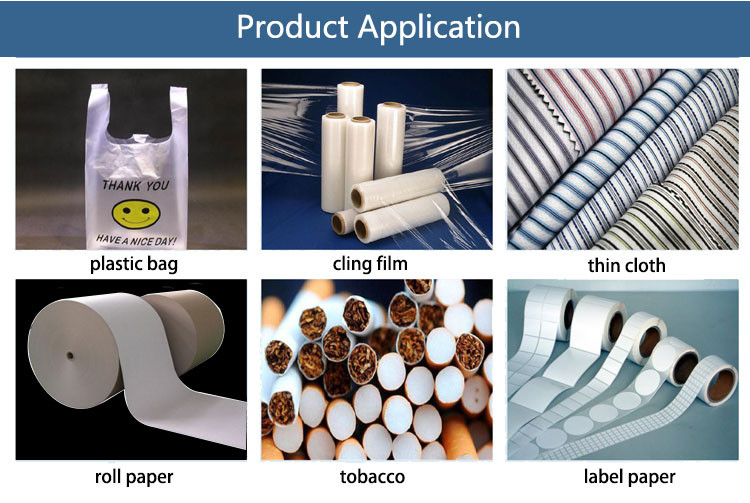

6,Versatile Applications

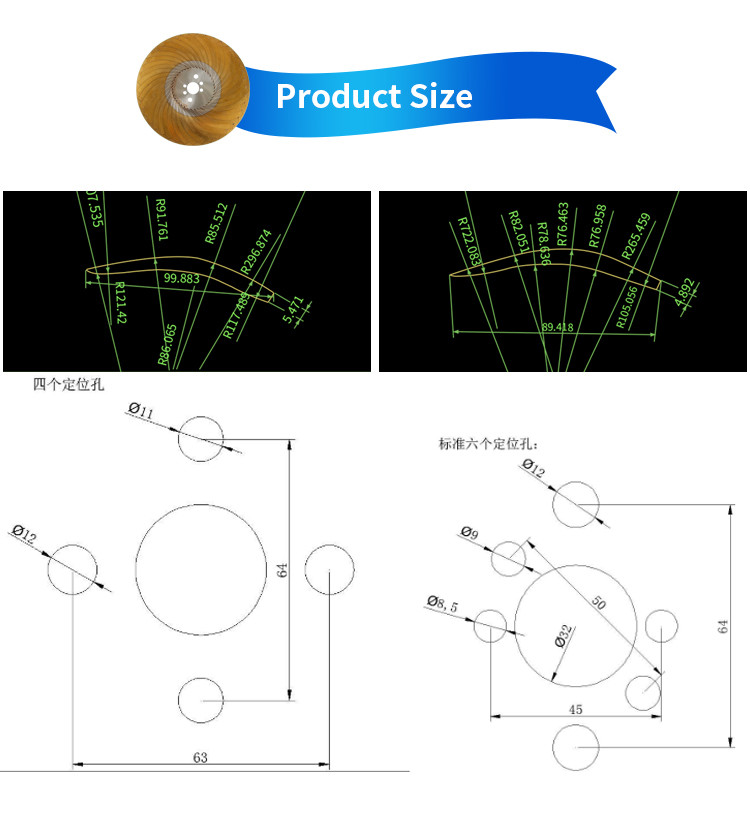

Rotary Slitter Blade Specifications:

| Product Name | Circular Slitting Knife Blades |

| Material | TCT |

| Precision | 0.01-0.03mm |

| Hardness | HRC 45~92 |

| Outer Diameter | 230mm |

| Thickness | 1.1mm |

| Inner Diameter | 110mm |

| Applicable Industries | Manufacturing Plant |

When selecting the appropriate size and specification of TCT (Tungsten Carbide Tipped) corrugated flat circular cutting blades, the following key factors should be considered:

1,Machine Equipment Requirements

2,Workpiece Material Characteristics

3,Cutting Precision Requirements

4,Cutting Speed Considerations

5,Economic Factors

Picture:

Size:

Applications:

Packing & Delivery:

|