| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Vacuum Belt Filter |

|---|---|

| Brand Name: | UNIVEE |

| Model Number: | U-BF |

| Place of Origin: | China |

| Certification: | ISO |

| MOQ: | 1 pcs |

| Price: | Customized |

| Payment Terms: | T/T, L/C |

| Supply Ability: | 1 set per 2 month |

| Delivery Time: | 8 weeks |

| Packaging Details: | Steel frame, Wooden Case, Tray, Suitable for multi transpiration |

| Name: | Filter |

| Chemical Resistance: | Excellent |

| Control: | PLC |

| Grade: | Standard |

| Framework: | Roller, Vacuum Box, Wear Belt |

| Belt Width: | 1200mm |

| Condition: | New |

| Voltage: | 380V |

| Frequency: | 50Hz |

| Service: | Available |

| Company Info. |

| Univee (Chongqing)Electrical Technology Co., Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

Chemical Industry Application Vacuum Belt Filter Anti-Corrosive Machine Automatic Control

The overall performance of a vacuum belt filter is improved where variations in parameters such as sludge type, feed solids concentration and conditioning are minimised.

In the compression zone of a belt press filter, the filter cake is compressed between the two belts and passed over rollers to exert pressure on the cake. There is an optimum number of rollers above which a drier product is not necessarily the result. Drier product is obtained from reduced belt speed rather than increased pressing time.

Vacuum belt filters are less effective at processing some feeds. Unless the feed is well mixed from a digester, the use of belt filters will be more costly when processing a feed with varying solids content as this requires more operator attention, raising staffing costs.

| Assembled frame block-design, it is very easy for transportation, installation and maintenance. |

| High automatic control; continuously automatic control of feeding, filtration, washing, dewatering, discharging, cloth washing; improve productivity efficiency; reduce operation cost; reduce the working strength of labors; improve working environment. |

| Convenience filtrating process; by adjusting the thickness of cake, amount of washing water, countercurrent washing grade, vacuum degree and speed of cloth can achieve to a best filtration efficient. |

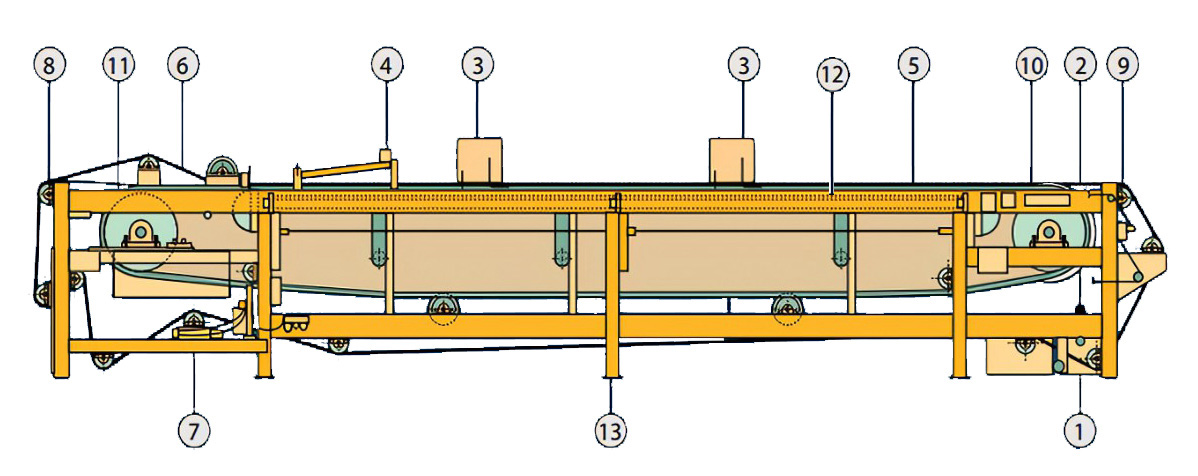

| 1 | Filter Cloth Washing | 8 | Filter Cloth Tension Unit |

| 2 | Belt Washing | 9 | Discharge Roll |

| 3 | Cake Washing Box | 10 | Drive Pulley |

| 4 | Slurry Feeding Hopper | 11 | Driven Pulley |

| 5 | Rubber Belt | 12 | Vacuum Box |

| 6 | Filter Cloth | 13 | Filter Support Frame |

| 7 | Filter Cloth Tracking Unit |

- Installation guidance and support

- Regular maintenance and inspection services

- Troubleshooting and repair assistance

- Technical training for operators and maintenance personnel

- Customization and engineering support for unique applications

- Replacement parts and accessories

- On-site support and emergency services

Q: What is the brand name of this product?

A: The brand name of this product is UNIVEE.

Q: What is the model number of this product?

A: The model number of this product is U-BF.

Q: What is a Vacuum Belt Filter?

A: A Vacuum Belt Filter is a type of filtration equipment used to

separate solids from liquids. It uses a horizontal belt made of

filter cloth to contain the solids and allow the liquid to pass

through.

|