| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Rack and Pinion Fiber Laser Cutting Machine |

|---|---|

| Brand Name: | Hoston |

| Model Number: | 2060 |

| MOQ: | 1 |

| Payment Terms: | L/C, T/T |

| Max.Cutting Speed: | 120m/min |

| Max,Acceleration: | 1.0G |

| X/Y Positioning Accuracy: | ±0.08mm |

| X/Y Repeated Positioning Accuracy: | ±0.02mm |

| Operating Voltage: | Operating Voltage |

| Company Info. |

| Jiangsu Hoston Machine Tools Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

CNC Metal Laser Cutting Machine 1500W 3000w Aluminum Steel Fiber Laser Cutting Machine Spare Parts

Cnc Metal Carbon Raycus IPG Rack&Pinion Fiber Laser Cutting Machine 1530

This machine is equipped with high-precision rack and guide rail

transmission mechanical structure. Through the advanced numerical

control system, the precision numerical control optical fiber laser

cutting machine is a high-tech product integrating laser cutting

machine, precision machinery, numerical control technology, etc.

The machine has good dynamic performance, can achieve high cutting

efficiency, and is equipped with a professional CNC system,which is

powerful, user-friendly and easy to understand.

It is mainly used for cutting and forming of carbon steel,

stainless steel, alloy steel, spring steel, galvanized sheet,

copper sheet, aluminum sheet and other metal plates, and is the

first choice for processing metal materials.

Max.Cutting Speed | 120m/min |

Max,Acceleration | 1.0G |

X/Y Positioning Accuracy | ±0.08mm |

X/Y Repeated Positioning Accuracy | ±0.02mm |

Operating Voltage | 380V/50HZ |

Laser power | 1500W-15000W |

Power consumption | 6KW |

Machine Running Temperature | 0°C-40°C |

Machine Running Humidity | <90% |

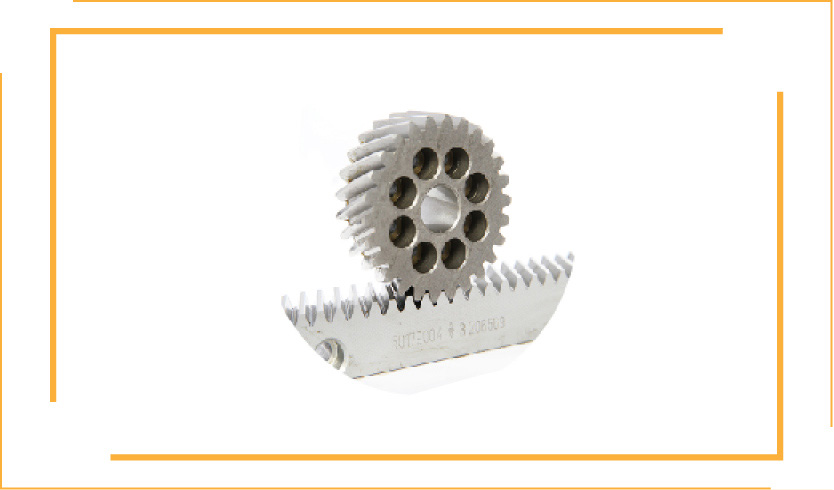

Transmission | Precise rack and pinion |

Model | Working Area(mm) | Total Weight(kg) | Machine Dimension(mm) |

| 1530 | 1500x3000 | 2600 | 5000x4200x2200 |

| 1540 | 1500x4000 | 5010 | 6000x4200x2200 |

| 2040 | 2000x4000 | 3500 | 6000x4800x2200 |

| 2060 | 2000x6000 | 5400 | 8400x4800x2200 |

| Machine Bed The bed has a smoke extraction port, which can automatically extract smoke through the smoke exhaust pipe, so that the smoke and dust generated during the cutting process can be easily discharged outdoors, improving the working environment. Beam part: The gantry beam design is adopted, which is light in weight, good in rigidity, good in dynamic performance, and stable in operation. The fully enclosed dustproof structure is adopted, which greatly improves the service life of the gear rack and linear guide rail installed inside. |

| Laser Ultra-high photoelectric conversion efficiency, up to 30% to 40%; Excellent pulse power stability; Long life, high precision, pump source life> 100,000 hours; High beam quality, faster speed, better effect; Using semiconductor optical fiber as the laser generating medium, no laser generating gas is required, green and environmentally friendly; Small size, light weight, maintenance-free. |  |

| Gear Imported gear rack, Taiwan PMI guide rail, Japan Yaskawa electric motor, higher stability. 1. Grinding gear making process, the accuracy level is DIN5, the cumulative error of accuracy is 0.012mm/300mm (any 300mm); 2. Helical tooth profile, adapt to various use conditions, dustproof, and ensure long-term high-precision movement. |

| Automatically adjust laser head The laser head adopts two-point centering adjustment, and the focus is driven by an imported motor. The efficiency in perforation is significantly improved. The protective lens is installed in a drawer and is easy to replace. By setting parameters, the focus scale can be flexibly adjusted without manual focus adjustment; the operation is convenient. Control the upper and lower height, automatically adjust the focus, quickly complete high-speed perforation of thick plates and automatically cut materials of different thicknesses. |  |

|