| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | New Energy PCB Assembly |

|---|---|

| Brand Name: | Suntek |

| Model Number: | F016-006 |

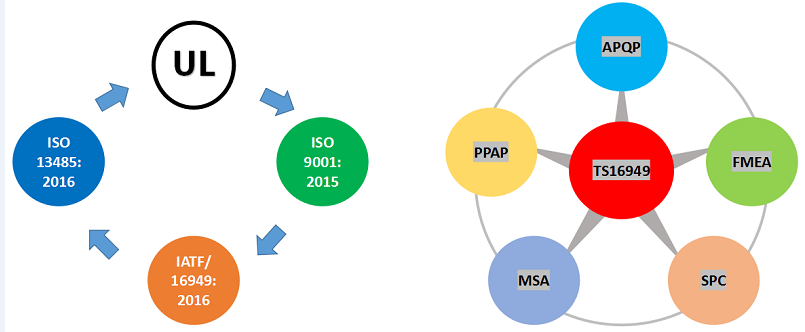

| Certification: | ISO9001 ISO13485 IATF16949 UL |

| Place of Origin: | China or Cambodia |

| MOQ: | 1 |

| Price: | Customized products |

| Payment Terms: | TT,Paypal |

| Delivery Time: | 5-7days after all components kitted |

| Packaging Details: | By ESD bags and carton |

| Material: | FR4(Tg130-Tg180) |

| Thickness: | 0.4mm-5mm |

| Layer: | 1L-32L |

| Size at max.: | 1200*400mm |

| Hole min.: | 0.1mm |

| Copper: | 0.5--10OZ |

| Surface: | HASL,ENIG,OSP,Hard plating,Immersion Tin |

| Solder mask: | Green,Blue,Black,Red,White,Matt color |

| Company Info. |

| Suntek Electronics Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

2mm PCB Assembly for New Energy products with RoHs and ISO9001 certified

A Contract Electronics Manufacturing Services Provider

Suntek Capability:

| Quality Grade | Standard IPC 2-3 |

| Assembly Technology | • SMD Stencils •PCB Fabrication • SMT PCB Assembly • THT assembly •

Cable and Wire Harness Assembly • Conformal Coating • Box Build Assembly • Final product assembly |

| Value Added Services | • Component Sourcing • Packing and delivery • DFM • Packing and

delivery • PCBA sample • Rework • IC Programming • NPI Report |

| Company Certifications | • ISO9001 • IATF16949 • ISO13485 • UL |

| Order Capacity | • No requirements of MOQ (Minimum Order Quantity) |

| Testing Process | • QC manual inspection • SPI(Solder Paste Inspection) • X-ray •

FAI(first article inspection) • ICT • FCT • Aging test • Reliability test |

One-Stop Solution EMS Service:

| OEM service | |||

| Layers | 1-32 Layers | Copper weight | 0.5 oZ~10 oZ |

| Material | FR4(Tg 135-Tg180) 94v0,Rogers,Aluminum | Board cutting | Shear,V-score,tab-routed |

| Board type | Rigid, flexable, rigid-flexable | Silk screen | Single double-sided green LPI etc |

| Board shape | Rectangular,round,slots,cutouts etc | Design file format | Gerber, CAD,.BRD |

| Board Thickness | 0.2~5.0mm,Flex 0.01~0.25“ | Bom format | Excel,PDF |

PCB Assembly

1)Our Equipments include Desen Printing press,Samsung SMT, JT lead-free re-flow ovens,

lead-free wave-soldering,BGA rework base,AI machine.

2) Surface mount,through-hole,BGA,QFP and QFN,0201 parts assembling.

3) AOl testing(X-ray for BGA package) for every piece board.

4)First article inspection before SMD process and First completed sample before DIP process.

5)Programming and function testing .

6)Conformal coating and Glue

PCBA/Wire Harness/Box build Quality System:

PCB Assembly equipments:

|