| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | High Alumina Brick |

|---|---|

| Place of Origin: | Henan, China |

| Shape: | Block, brick |

| Material: | Alumina Cement |

| SiO2 Content (%): | 0.3-15% |

| Al2O3 Content (%): | 65-70% |

| MgO Content (%): | 0.8-1.2% |

| CaO Content (%): | 0.2-0.4% |

| Refractoriness (Degree): | Common (1580°< Refractoriness< 1770°) |

| CrO Content (%): | 0.1-0.3% |

| SiC Content (%): | 1.2-1.4% |

| Model Number: | hongtai |

| Brand Name: | HT |

| Product name: | high alumina anchor brick |

| Application: | Blast Furnace |

| Bulk Density(g/cm3): | 2.0-2.5g/cm3 |

| Raw material: | high alumina bauxite |

| Size: | Customized Size |

| Certificate: | ISO9001 |

| Sample: | sample provide |

| Color: | Gray |

| Type: | manufacturer |

| Packaging Details: | Fumigated wooden pallet, using paper or non-woven fabrics between layers separated,plastic shrink film protected outside.finally using straps. Or as your requirements.

Shipping: By vessel or train from Chinese ports. |

| Supply Ability: | 30000 Piece/Pieces per Month |

| Price: | $10.00 - $50.00/pieces |

| Company Info. |

| Henan Hongtai Kiln Refractory Co.,Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

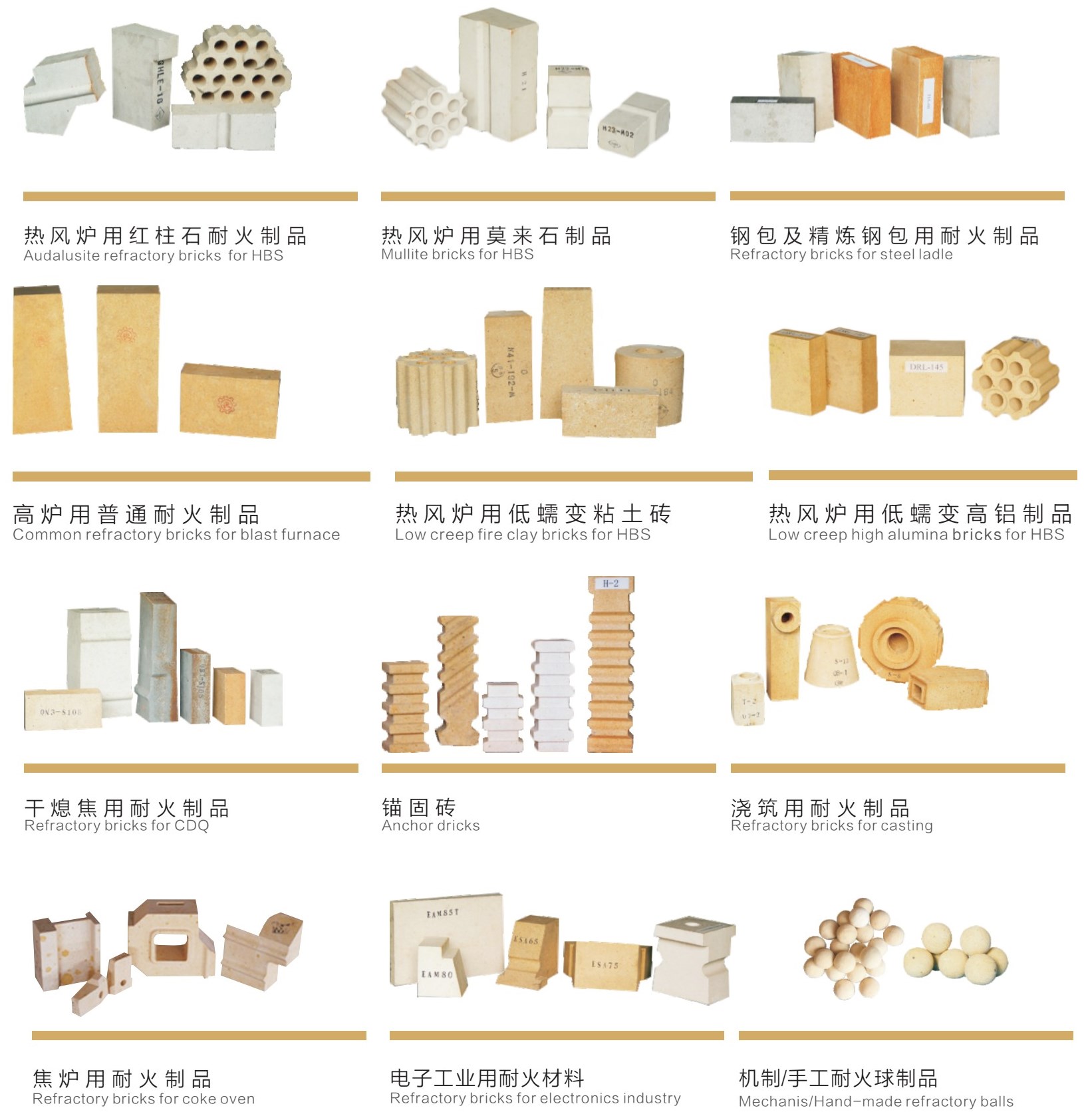

High quality Anchor Brick refractory anchor brick for furnace wall

Anchor brick is an anchor brick for industrial furnace (hanging brick), especially relates to an anchor brick for industrial furnace roof, comprising a column composed of a hanging end and an anchor, which is opened on the surface of the anchor. The grooves are spaced apart, and the ribs are arranged along the length direction on at least one surface of the anchor body. After the ribs are arranged, the tensile strength of the anchor is obviously improved due to the reinforcement and pulling action of the ribs, and the groove is at the groove The generated stress is blocked at the ribs and cannot be transmitted continuously, so the anchor brick of this structure is not easily broken. The industrial furnace or flue wall is roughly composed of an inner lining layer, a heat insulating layer and an outer wall layer, the inner lining is a refractory brick, the outer wall is a common sintered brick, and the anchoring brick is divided into two types: a hanging brick and a perforated brick.

Low creep high aluminum/clay anchor brick:

Low creep high alumina brick is made of special grade aluminum

bauxite clinker as main raw material, supplemented by special

additives, high pressure forming, high temperature firing, high

heat storage capacity and small creep rate, suitable for small and

medium sized blast furnaces. Supporting hot air stove.

Low-creep high-aluminum anchor bricks are indispensable refractory bricks for thermal furnaces such as heating furnaces and coal chemical furnaces. Anchor bricks are mainly used for anchoring refractory castables. The properties of anchor bricks should be consistent with the material of castables. The shrinkage is consistent so that it can form a tight bond with the castable and extend the life of the lining.

Anchor brick is a new type of anchor brick for industrial furnace, in particular to an anchor brick for industrial furnace roof, comprising a column composed of a hanging end and an anchor, and a space distribution on the surface of the anchor. The groove is provided with ribs along the length direction on at least one surface of the anchor body. After the rib is set, the tensile strength of the anchor is obviously improved due to the reinforcement and pulling action of the rib, and the stress generated at the groove is increased. Obtaining the barrier at the ribs cannot continue to be transmitted, so the anchor bricks of this structure are less prone to breakage. The anchor bricks are divided into two types: hanging bricks and perforated bricks. The anchor bricks produced by our company are machine-formed and fired at high temperature, with high strength, good anti-scourability and high peeling resistance.

The main points of masonry of anchor bricks are as follows:

1. When laying bricks, carefully apply mud from both sides to

prevent gas leakage from the top of the furnace;

2, should be topping, to ensure the size of the joints, correctly

determine the hanging metal parts;

3. There should be no loss in the hanging part of the hanging brick

(to give full play to the role of hanging metal parts);

4, generally use air hardening mud (to prevent gas leakage caused

by mud off);

5. Expansion joints should be properly placed between the furnace

body and the hanging bricks.

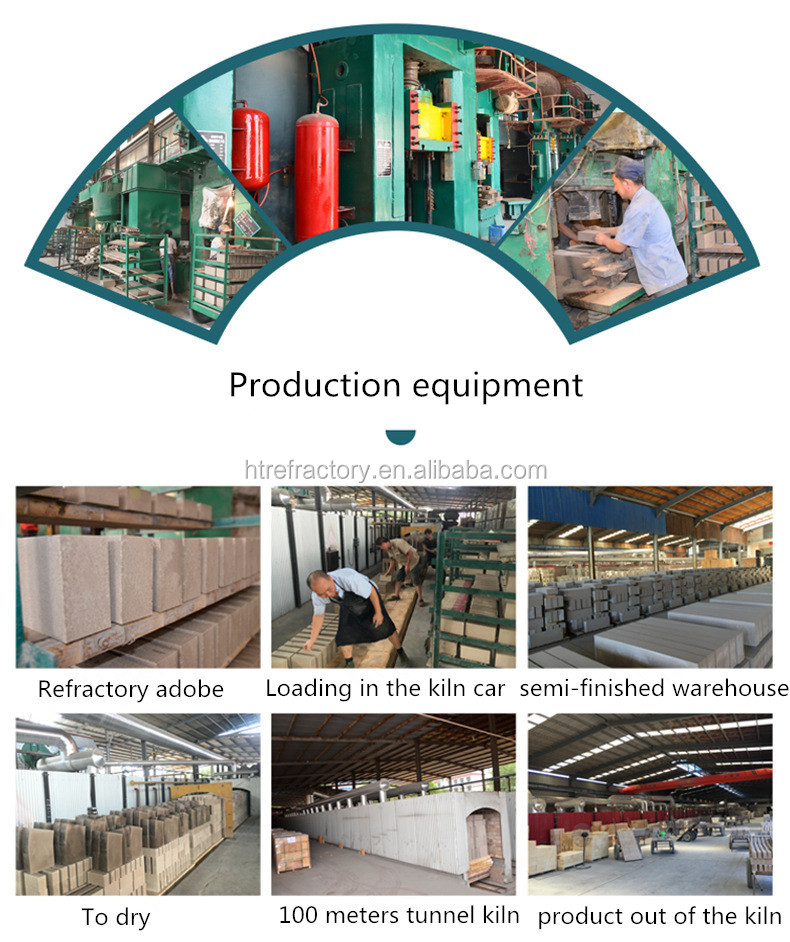

Workshop corner

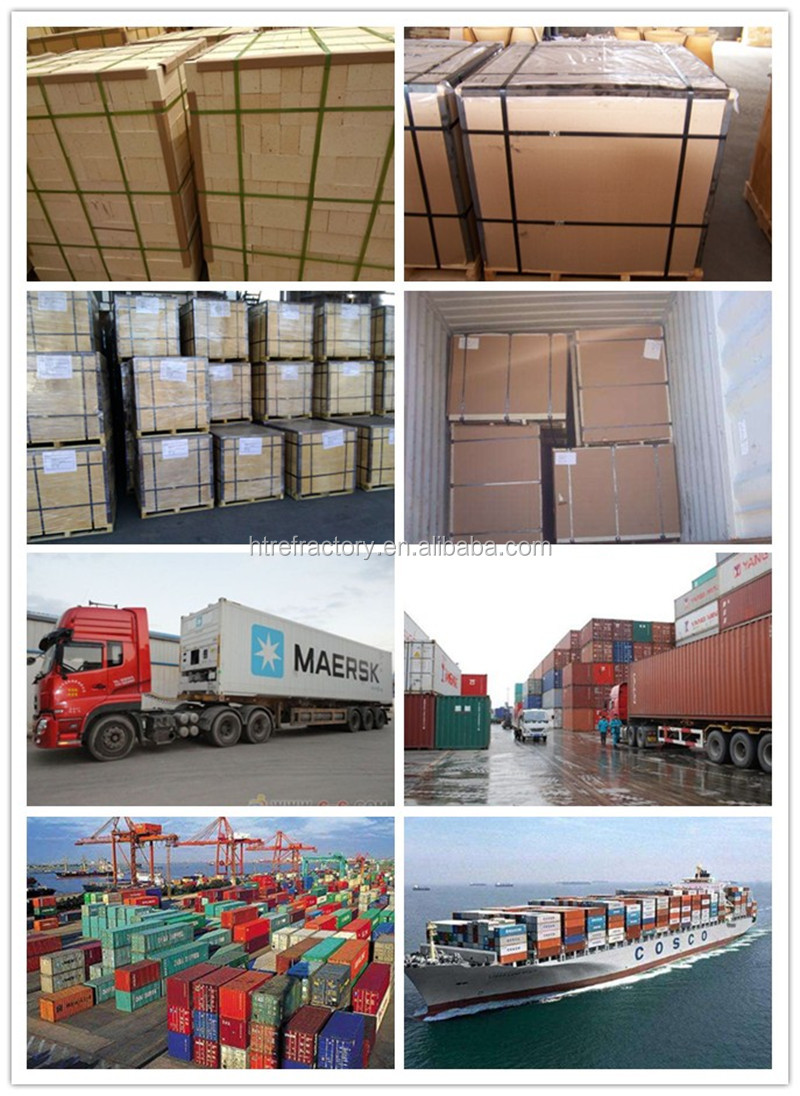

Packaging of diatomaceous bricks

1.on wooden pallets with plastic cover: wooden pallet size :930*930

or 1000*1000mm,

2.Load weight of each pallet: 1.5-2.0 tons,

3.230*114*65mm:512PCS/Pallet, 230*114*75mm:448PCS/Pallet.

Shipping of diatomaceous bricks

1.Our packaging is as per customer’s request

2.Normal goods delivered by sea transport

3.Sample shipping by express

4.We will shipping and delivery goods timely, quanlity and quantity

guaranteed, and also in accordance with the contract and customer's

requirment completely.

1.Production Process

1)Raw material to factory→checkout→burdening→stirring→mixing→taking

out the raw material,

2)Crushing→Mixing→Shaping→Drying→Firing→Inspection→Packaging and

Shipment.

2.Quality Assurance Process

1)Going out the furnace→checkout→packing→qualified product→putting

in storage→sale,

2)The process from raw to product are strictly tested by equipment.

1.Inspection and Control of incoming raw materials: according to

the chemical content,raw materials are classified into different

levels to ensure quality of brick first.

2.Inspection and control of the process: during the

production,every brick will be weighed twice strictly to reduce the

error of weight .

3.Quality audit by quality management: inspection of product

standardization of quality of each product by process control and

experimentation, taking corrective measures timely whenever

deviations are noted.

4.Before delivery, the inspectors will inspect the size,appearance,

physical and chemical properties of brick again in factory.

|