| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | CNC Milling Parts |

|---|---|

| Brand Name: | ODM,OEM |

| Model Number: | PUSHER-CMS-2 |

| Place of Origin: | Jiangsu,China |

| MOQ: | 1 pieces\1 set |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union |

| Supply Ability: | 1000000 pieces per year |

| Delivery Time: | 7-15 work days |

| Packaging Details: | Carton. Dimension: 33(cm)X34(cm)X35(cm) |

| Material: | Aluminum,Brass,Stainless Steel,Steel Alloys |

| Finish: | Cleaning and anodizing |

| Specification: | customization |

| Color: | As required |

| Usage: | Aerospace Industry |

| Product Advantages: | High Precision |

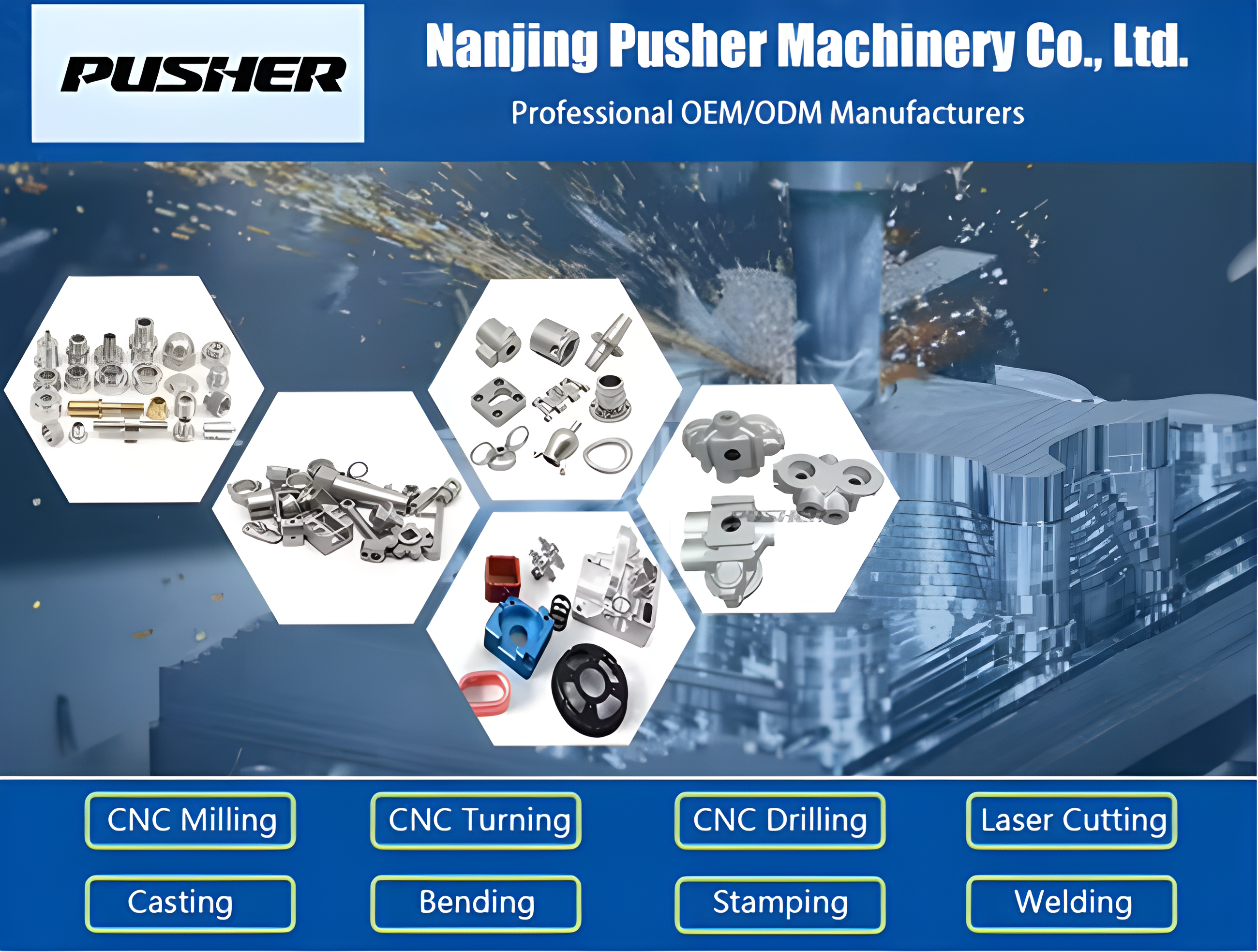

Professional CNC Manufacture for Frame Alodine Coating Aluminum Machined Parts

Product Paramenters

| Processing | CNC Turning, CNC Milling, Laser Cutting, Bending, Spinning, Wire Cutting, Stamping, Electric Discharge Machining (EDM), Injection Molding |

| Size | Customized |

| Technics | laser cut, bend, weld, stamp |

| Drawing Format | 3D/CAD/Dwg/IGS/STP |

| Materials | Stainless steel/Aluminum/Steel/Brass/Plastic |

| Surface Treatment | Anodized, Plating, Brushing, Painting, Powder Coated, Passivation, Electrophoresis, Polishing |

| Heat treatment | Nitriding, Tempering , Carbonitriding |

| Inspection | 100 % inspection |

Product display

Surface Treatment

Plating: Coating the surface of the part with a layer of metal (such as chrome, nickel, or copper) to improve its appearance, corrosion resistance, and conductivity.

Nitriding: Reacting nitrogen gas with the metal surface at high temperatures to form a wear-resistant and corrosion-resistant nitride layer, increasing the hardness and wear resistance of the part.

Application

Electronics Industry: CNC milling is utilized in the production of electronic enclosures, heat sinks, connectors, and other precision components for electronic devices.

Prototyping and Rapid Manufacturing: CNC milling is also employed in rapid prototyping and manufacturing of custom parts for various industries, allowing for quick iterations and production of prototypes or small batches.

Packing&Shipping

About PUSHER

It is very convenient to be reached with an advantageous geographic position; the foundry is equipped with several types of energy-saving & environmentally friendly production lines including automatic or semi-automatic production lines of key processes: wax making, shell making, pouring, heat treatment.

The machining factory is in headquarters and is fully equipped with complete and advanced CNC machining equipment including thirty vertical and horizontal machining centers, and more than 30 CNC machines and fifty other machining equipment., the machining facility is fully independent from the casting foundry and has an independent management team and tailored business model to suit. In addition to the casting, forging, and machining, it also has the facility to machine various profiles.

FAQ

Q: Why do you choose us?

Ella: Responsibility, Efficiency, Loyalty, Win-Win, Punctuality,

Cost effectiveness.

|