| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | CNC Turning Accessories |

|---|---|

| Brand Name: | ODM,OEM |

| Model Number: | PUSHER-CTP |

| Place of Origin: | Jiangsu,China |

| MOQ: | 1 pieces\1 set |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union |

| Supply Ability: | 1000000 pieces per year |

| Delivery Time: | 7-15 work days |

| Packaging Details: | Carton. Dimension: 33(cm)X34(cm)X35(cm) |

| Material Capabilities: | Aluminum, Brass, Bronze, Copper, Hardened Metals, Precious Metals, Stainless steel, Steel Alloys |

| Keyword: | CNC Precision Machining Parts |

| Size: | Customized |

| Surface treatment: | Customized |

| Package: | Carton Package |

| MOQ: | 1 Piece |

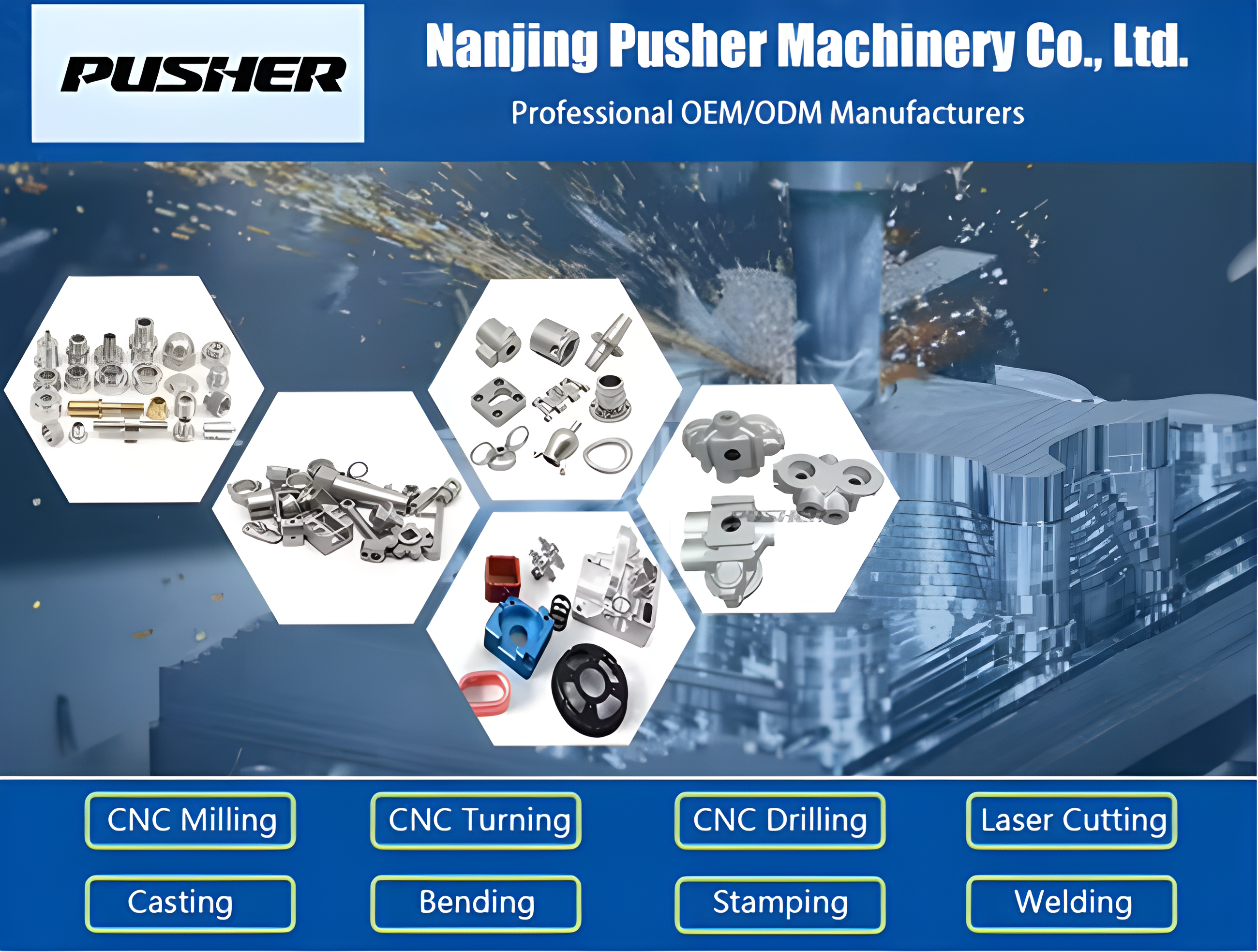

Customization Service for High Precision Cnc Turning parts Machining parts of Medical Equipment

Product Paramenters

| Manufacturing Service | CNC machining,milling,turning,grinding, wire EDM cutting,cnc prototype/jig/fixture,laser cutting,other metal fabrication,like Stamping,Bending,Casting.etc. |

| Tolerance | highest = +/-0.005mm or +/- 0.0002 inch |

| Surface Roughness | Ra0.4 (milled or turned without polishing or grinding) |

| Finish | polishing,mirror polishing,brushing, sandblasting, heat treatment etc. |

| Surface Treatment | anodizing,blackening,electroplating(zinc,nickel,chrome),electrophoresis, painting,powder coating,passivate,carburize etc. |

| Logo | laser engraving, CNC engraving, screen-printing etc. |

Product display

Surface Treatment

Hardening:

Hardening treatments, such as induction hardening or case hardening, are applied to specific areas of CNC turning parts to increase surface hardness and wear resistance while maintaining the desired mechanical properties in the core. This is commonly used for components subjected to high levels of wear and abrasion.

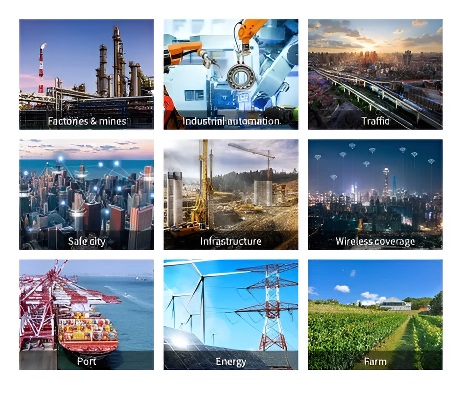

Application

Industrial Machinery:

Industrial machinery relies on turned parts for components such as shafts, bearings, couplings, and hydraulic system parts. These parts contribute to the smooth operation and reliability of machinery used in manufacturing, construction, and other industrial applications.

About US

PUSHER is a professional manufacturer of deep drawing & stamping parts, especially precision deep drawn parts & stamping parts, deep drawn automobile parts,sensor housings, pump and valve components, refrigeration and air-conditioning parts, stainless steel battery housing, auto stamping parts, sheet metal fabrication etc.

Certificates

Packing

Shiping

Dear Customers,

Nice to meet you! We provide metalwork services with CNC MACHINING,

SHEET METAL FABRICATION and STEEL FABRICATION, and all products are

customized.

If you need a SAMPLE to check the quality, please feel free to

contact us.

To get a quote quickly, please provide the following information

and we will reply ASAP.

*Detailed drawings

They should including material, dimensions, tolerances, surface

treatment, etc.

*Quantity per order

It is essential.

*3D file

It can speed up our quotation as well as the accuracy.

|