| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Steel Fabrication Parts |

|---|---|

| Brand Name: | ODM,OEM |

| Model Number: | PUSHER-SFP |

| Place of Origin: | Jiangsu,China |

| MOQ: | 1 pieces\1 set |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union |

| Supply Ability: | 1000000 pieces per year |

| Delivery Time: | 7-15 work days |

| Packaging Details: | Carton. Dimension: 33(cm)X34(cm)X35(cm) |

| Process: | Stamping, Stamped, Laser Cutting |

| Material: | Stainless Steel, Aluminum, Brass |

| Application: | Used Widely |

| Tolerance: | 0.01-0.05mm |

| Keyword: | Metal Stamping Parts Sheet Metal Fabrication |

| Size: | Customized Size is ok |

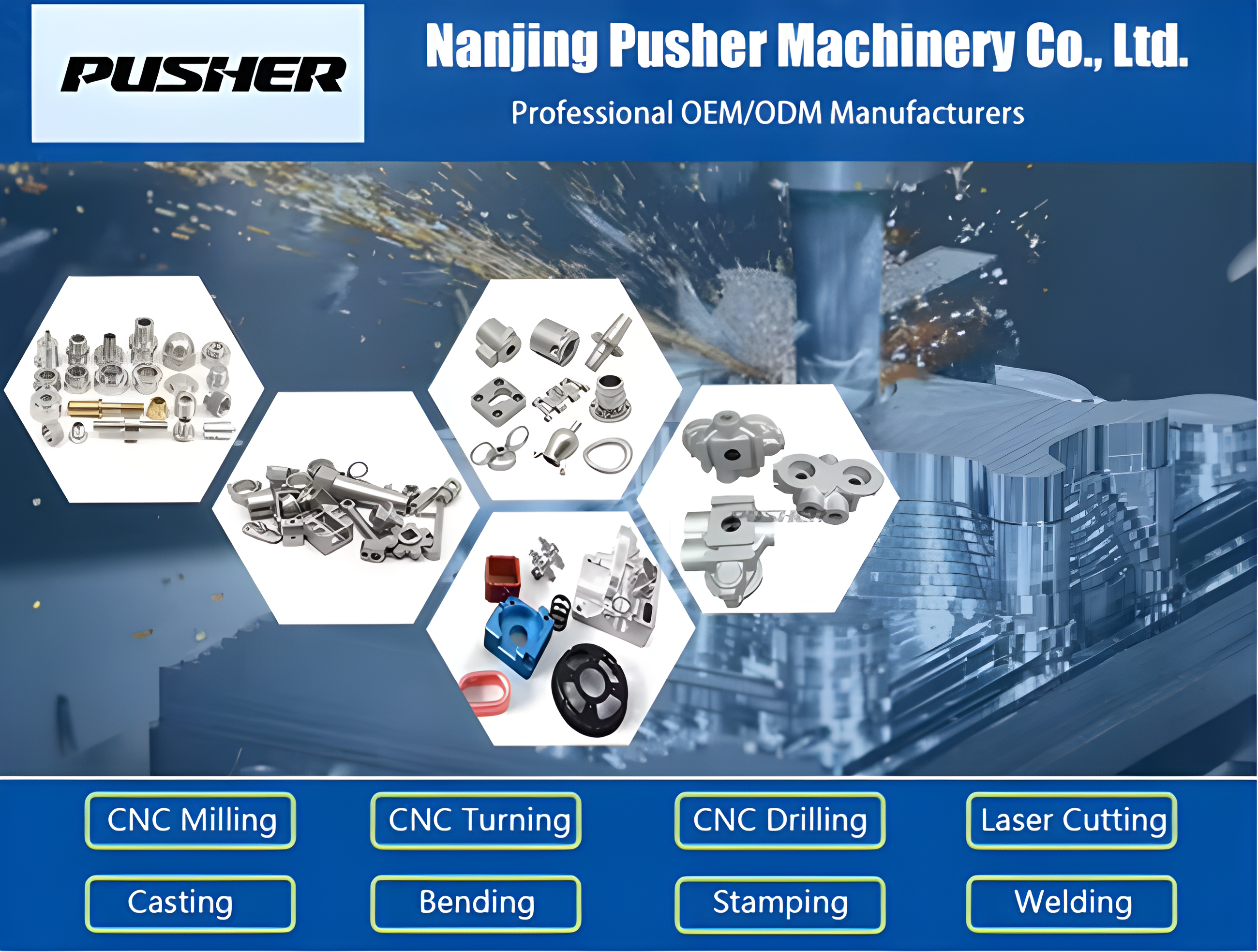

OEM High Precision Bending Punching Metal Stamping Parts Sheet Metal Fabrication

Material | 1) Aluminum: AL 6061-T6, 6063, 7075-T etc. |

2) Stainless steel: 303,304,316L, 17-4(SUS630) etc. | |

3) Steel: 4140, Q235, Q345B,20#,45# etc. | |

4) Titanium: TA1,TA2/GR2, TA4/GR5, TC4, TC18 etc. | |

5) Brass: C36000 (HPb62), C37700 (HPb59), C26800 (H68), C22000(H90)

etc. | |

6) Copper, bronze, Magnesium alloy, Delrin, POM,Acrylic, PC, etc. | |

Finish | Sandblasting, Anodize color, Blackenning, Zinc/Nickl Plating,

Polish. |

Power coating, Passivation PVD, Titanium Plating,

Electrogalvanizing. | |

Electroplating chromium, electrophoresis,

QPQ(Quench-Polish-Quench). | |

Electro Polishing,Chrome Plating, Knurl, Laser etch Logo, etc. | |

Main Equipment | CNC Machining center(Milling), CNC Lathe, Grinding machine. |

Cylindrical grinder machine, Drilling machine, Laser Cutting

Machine,etc. | |

Drawing format | STEP,STP,GIS,CAD,PDF,DWG,DXF etc or samples. |

Tolerance | +/-0.01mm ~ +/-0.05mm |

Surface roughness | Ra 0.1~3.2 |

Inspection | Complete inspection lab with Micrometer, Optical Comparator,

Caliper Vernier,CMM. |

Depth Caliper Vernier, Universal Protractor, Clock Gauge, Internal

Centigrade Gauge. | |

Capacity | CNC turning work range: φ0.5mm-φ150mm*300mm. |

CNC milling work range: 510mm*1020mm*500mm. |

Product display

Quality Control

Surface Treatment

Painting: Applying paint to the surface of the steel components to form a protective layer, preventing corrosion. Various types of paints can be used, including anti-rust paint, epoxy paint, etc., depending on the requirements.

Application

Mechanical Manufacturing: Steel fabrication parts are widely used in the manufacturing of various mechanical equipment.

About us

Nanjing Pusher Machinery Co.,Ltd. is specializing in customized-made CNC machining and welding, casting, forging. With over 10 years’ experience in the field. Our Precision Machining, innovative, with an unique design and superior quality, are suitable for any kind of medical, automotive, consumer goods, aerospace, energy, and robotics. and will meet your needs.With a massive R&D environment, Pusher took advantage of market-leading technology and introduced various of advanced equipment to guarantee the rigorous quality in production.

Product Packaging

Certificates

FAQ

Q:Can I get samples for testing?

A:samples will be charged.

|