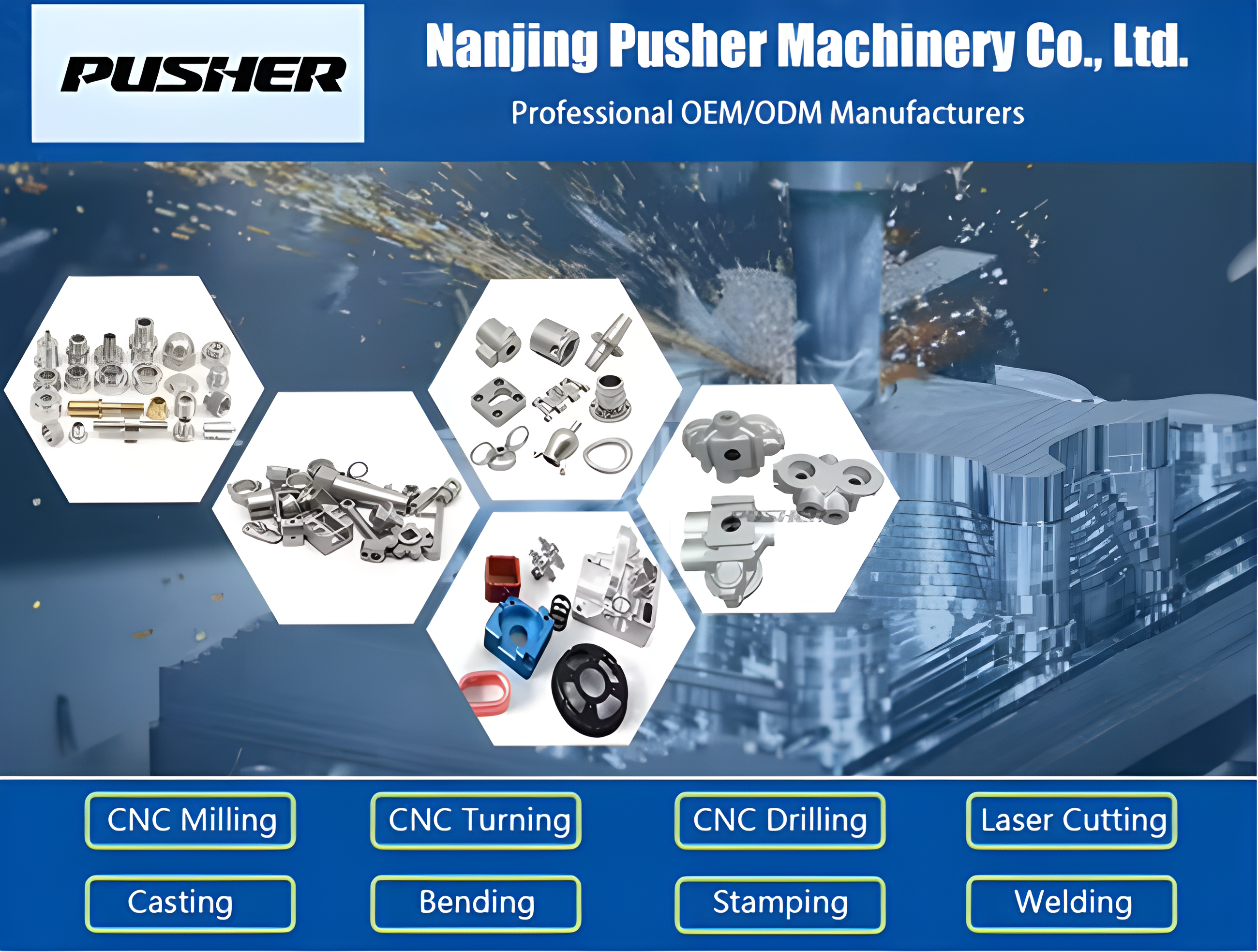

Nanjing Pusher Machinery Co., Ltd

Company Description:

Our company is a large-scale professional investment casting

foundry with powerful machining capabilities in China. and the

products are exported to North America, South America, Europe,

Southeast Asia, Middle east, and other destinations around the

world.

Located in 1005 room, 20 Songfeng Road,Jiangning District Nanjing

China. It is very convenient to be reached with an

advantageous geographic position;

The machining factory is in headquarters and is fully equipped with

complete and advanced CNC machining equipment including thirty

vertical and horizontal machining centers, and more than 30 CNC

machines and fifty other machining equipment., the machining

facility is fully independent from the casting foundry and has an

independent management team and tailored business model to suit. In

addition to the casting, forging, and machining, it also has the

facility to machine various profiles. Our company also has advanced

inspection equipment, including Spectrometer, Metallographic

Microscope, Tension Tester, Low Temperature Tester, X-ray Tester,

MPT, UT, CMM, Video Measurement Machine and so on. With these

advanced facilities & instruments, we can supply the high-quality

castings to our customers and make products meeting comprehensive

inspection requirements on chemical composition, mechanical

properties, non-destructive testing, and high precise dimensional

inspections.

With a massive R&D environment, Pusher took advantage of

market-leading technology and introduced various of advanced

equipment to guarantee the rigorous quality in production. Our

products cover a wide range of industries including train &

Railway, automobile & Truck, construction machinery, mining

machinery, forklift, agricultural machinery, shipbuilding,

petroleum machinery, construction, valve and pumps, electric

machine, hardware, power equipment and so on. We are capable to

produce products according to customers' drawings or samples, we

focus on both steel. Up to today, more than 100 raw materials and

5, 000 kinds of different products have been developed and produced

by us.

Product Description:

- Our Commitment:

- Advanced processing equipment

- All-round processing technology

- Timely delivery of precision machined parts

- Meet customer requirements

- To provide customers with defect-free parts

The custom machining services that we can offer:

CNC Machining Parts

Casting Parts

Fabrication Parts

CNC Turning Parts

CNC Milling Parts

Metal Stamping Parts

Forging Parts

We are committed to ensure to complete your custom projects as

below:

- Within the timeframe

- Within the budget

- Meeting the quality standard

We can design and make precision parts according to customers'

samples, drawing and AutoCAD or Pro/E file.

Trade Capacity:

| International Commercial Terms | FOB, CIF, CFR |

| Terms of Payment | PayPal, LC, T/T, D/P |

| Average Lead Time | Two weeks |

| Number of Foreign Trading Staff | 10 |

| Main Markets | Abroad |

| Nearest Port | Shanghai Port / Ningbo port |

| Import & Export Mode | Have Own Export License |

Nanjing Pusher Machinery Co., Ltd is an innovative, growth

oriented, small-sized family-owned enterprise and industry leader

in the design, manufacturing, and marketing of technically industry

parts. As to non-standard parts, we are professional in machining

and casting parts.