| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Metal Stamping Parts |

|---|---|

| Brand Name: | OEM |

| Model Number: | Pusher-MSP |

| Place of Origin: | Jiangsu, China |

| MOQ: | 1pc \1 set |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, |

| Supply Ability: | 1000000 pcs per year |

| Delivery Time: | 7-15 days |

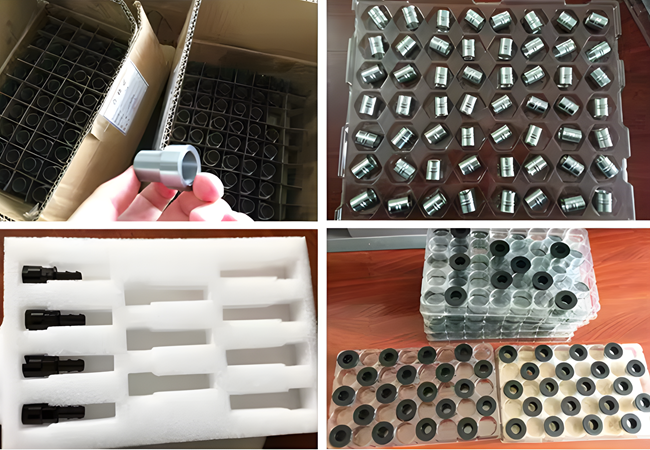

| Packaging Details: | CARTON 33cm X34 cm X19 cm |

| Product name: | Fabrication Stamping Part |

| Surface treatment: | Mirror Polishing, Anodize,Electroplating,Oxide,Sandblasting |

| QC Control: | 100% QC Steps Inspection |

| Our Service: | Custom Machining CNC Services |

| Material: | Stainless steel, brass, copper, aluminum, carbon steel, alloy steel |

| Tolerance: | ±0.01-0.05mm |

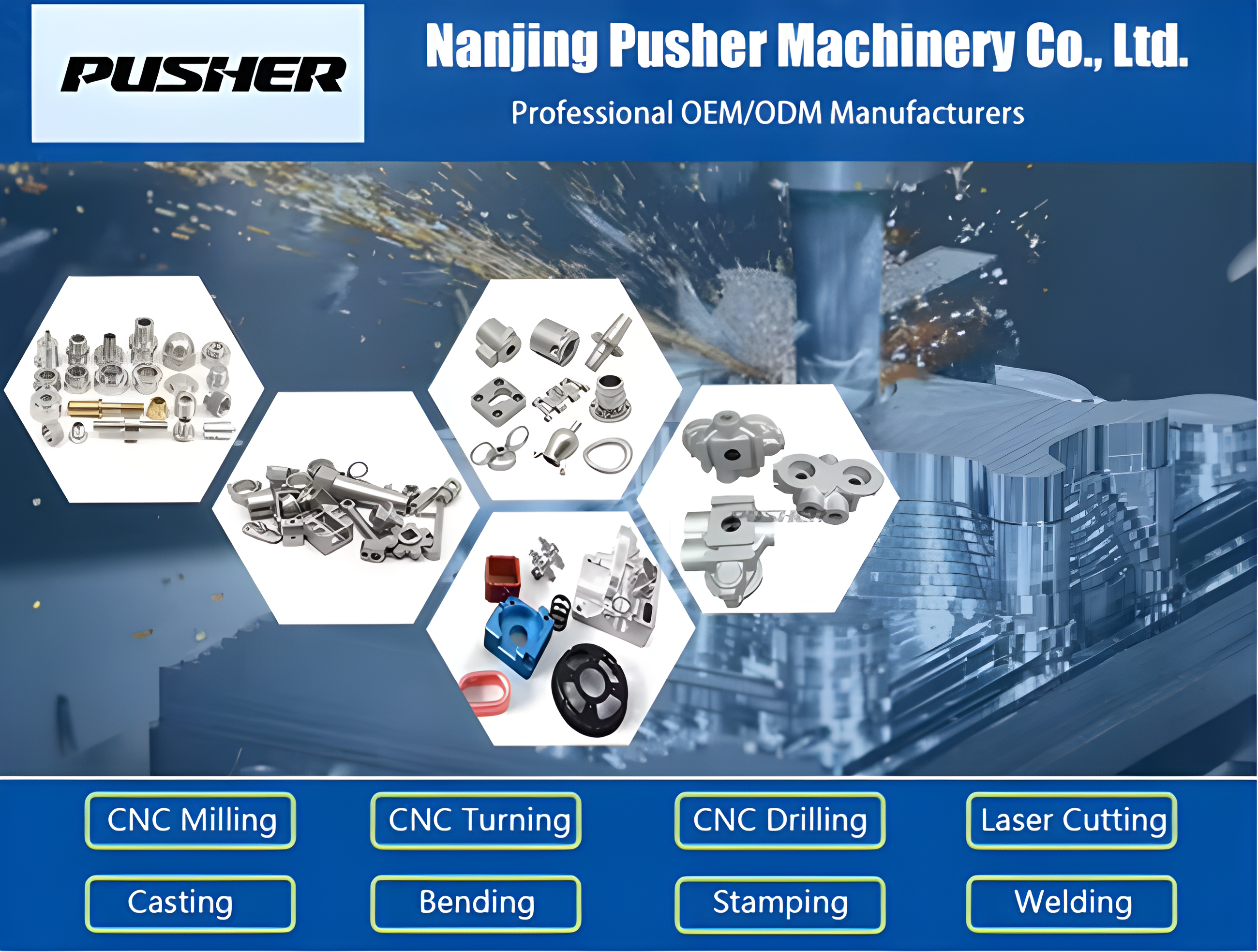

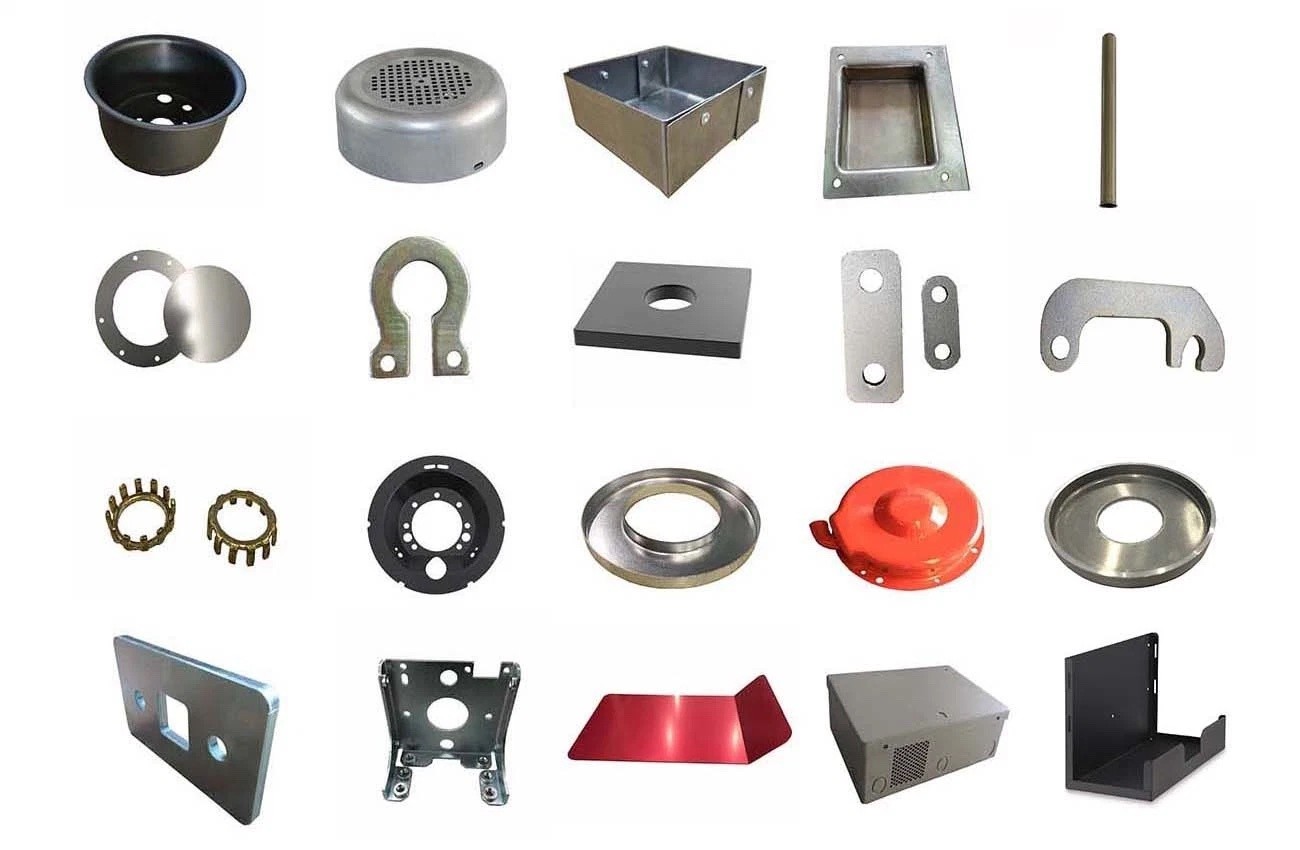

OEM Laser Cutting and Logo Fabrication Services for Custom Sheet Metal Stamping Parts

(1) The stamped parts have high dimensional accuracy.

(2) Stamping processing has good stability, and stamping parts from the same batch can be interchanged without affecting assembly and product performance.

(3) Since stamping parts are made of sheet metal, their surface quality is good, which provides convenient conditions for subsequent surface treatment processes (such as electroplating and spray painting).

(4) Stamping processing can obtain parts with high strength, high rigidity and light weight.

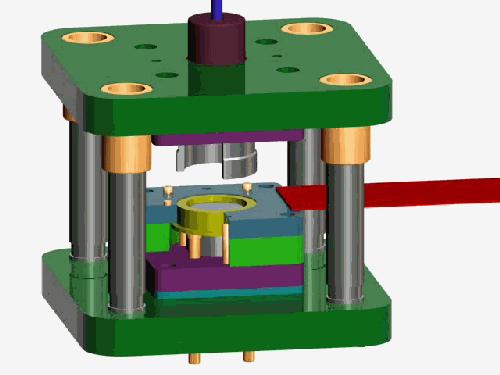

(5) The cost of stamping parts produced in batches with molds is low.

(6) Stamping can produce parts with complex shapes that are difficult to process with other metal processing methods.

Sandblasting: High-pressure airflow is used to propel sand particles onto metal surfaces to improve surface texture and increase roughness.

Shot blasting: Similar to sandblasting, but using metal particles, it can remove surface oxidation and impurities, improving coating adhesion.

|