| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Metal Stamping Parts |

|---|---|

| Brand Name: | OEM |

| Model Number: | Pusher-MSP |

| Place of Origin: | Jiangsu, China |

| MOQ: | 1pc \1 set |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, |

| Supply Ability: | 1000000 pcs per year |

| Delivery Time: | 7-15 days |

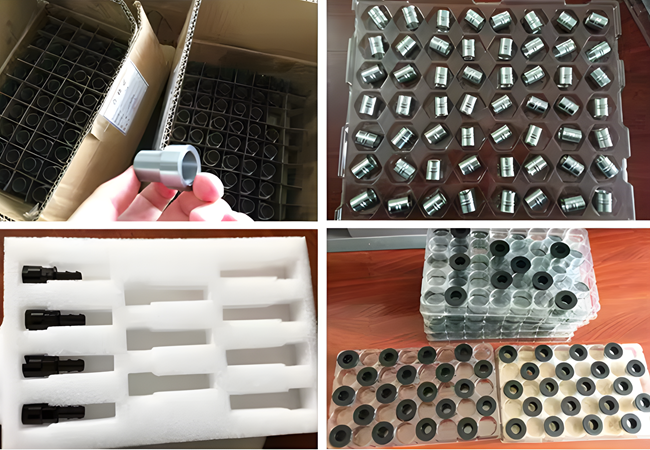

| Packaging Details: | CARTON 33cm X34 cm X19 cm |

| Product name: | Metal sheet stamping part |

| Type: | Metal parts, Spare part, Lighting stamping parts |

| Application: | Lighting, Car, equipment |

| Finish: | Zinc plated, nickel plated, polishing, chrome plated,black, coated |

| How to get the goods: | customized |

| Material: | metal, iron, carbon steel, stainless steel, brass, galvanized steel |

| Company Info. |

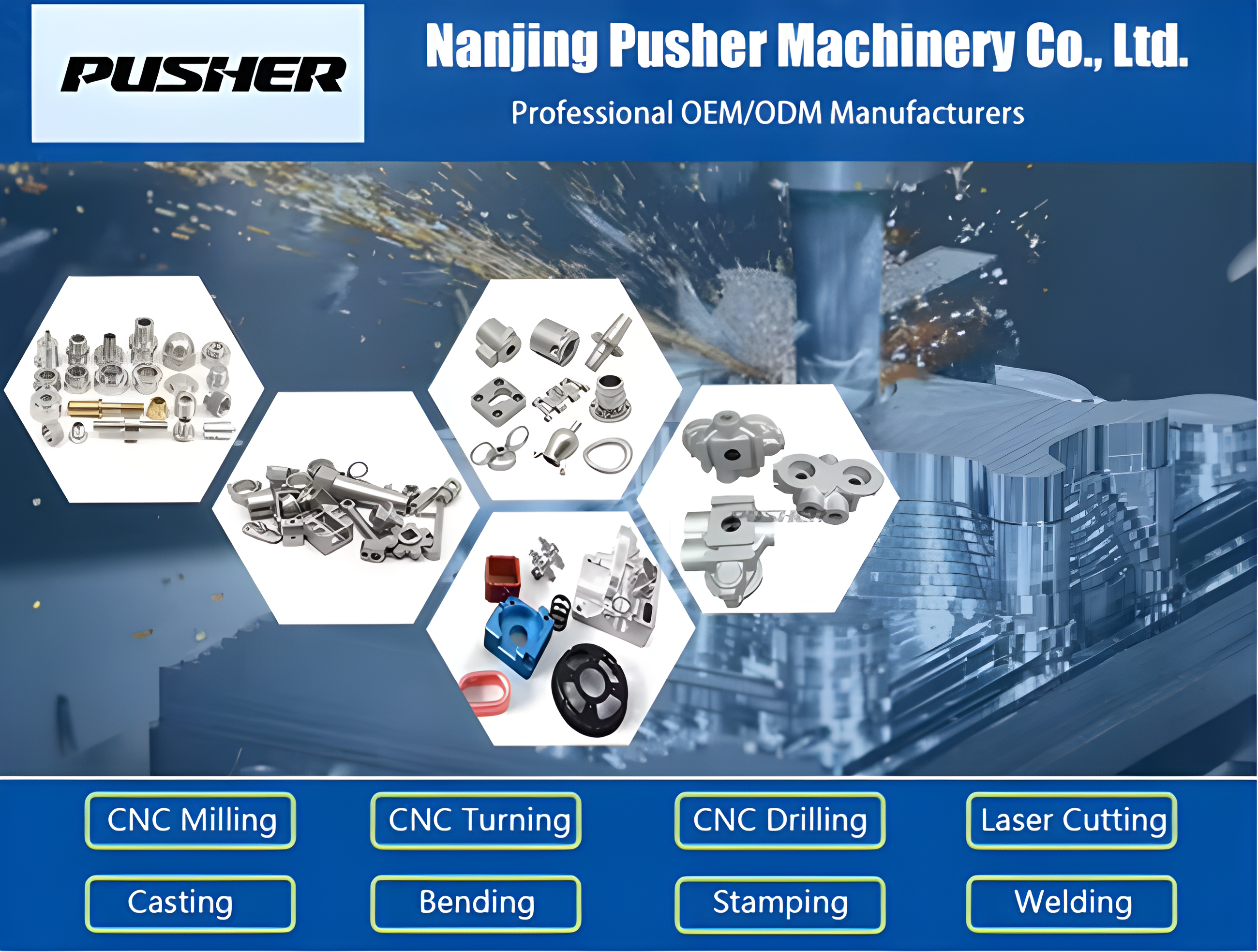

| Nanjing Pusher Machinery Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

Custom High Precision Stamping Parts with Competitive Sheet Metal Press Parts Service

(1) The stamped parts have high dimensional accuracy.

(2) Stamping processing has good stability, and stamping parts from the same batch can be interchanged without affecting assembly and product performance.

(3) Since stamping parts are made of sheet metal, their surface quality is good, which provides convenient conditions for subsequent surface treatment processes (such as electroplating and spray painting).

(4) Stamping processing can obtain parts with high strength, high rigidity and light weight.

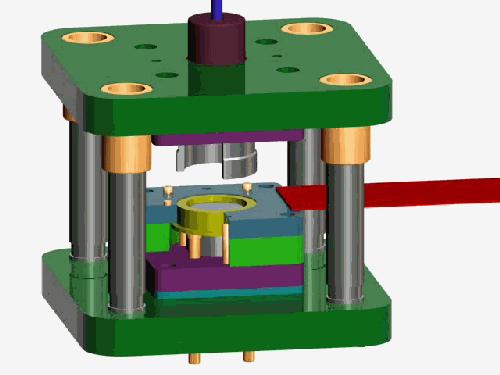

(5) The cost of stamping parts produced in batches with molds is low.

(6) Stamping can produce parts with complex shapes that are difficult to process with other metal processing methods.

Plating: Including galvanization, nickel plating, chromium plating, copper plating, etc., to provide corrosion resistance and aesthetic appeal.

Oxidation: Metal surfaces can undergo oxidation treatment, such as anodizing aluminum, to improve corrosion resistance and hardness.

Q: Do you accept custom design on size?

|