| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Fire Rated ACP Sheets |

|---|---|

| Brand Name: | richly bound |

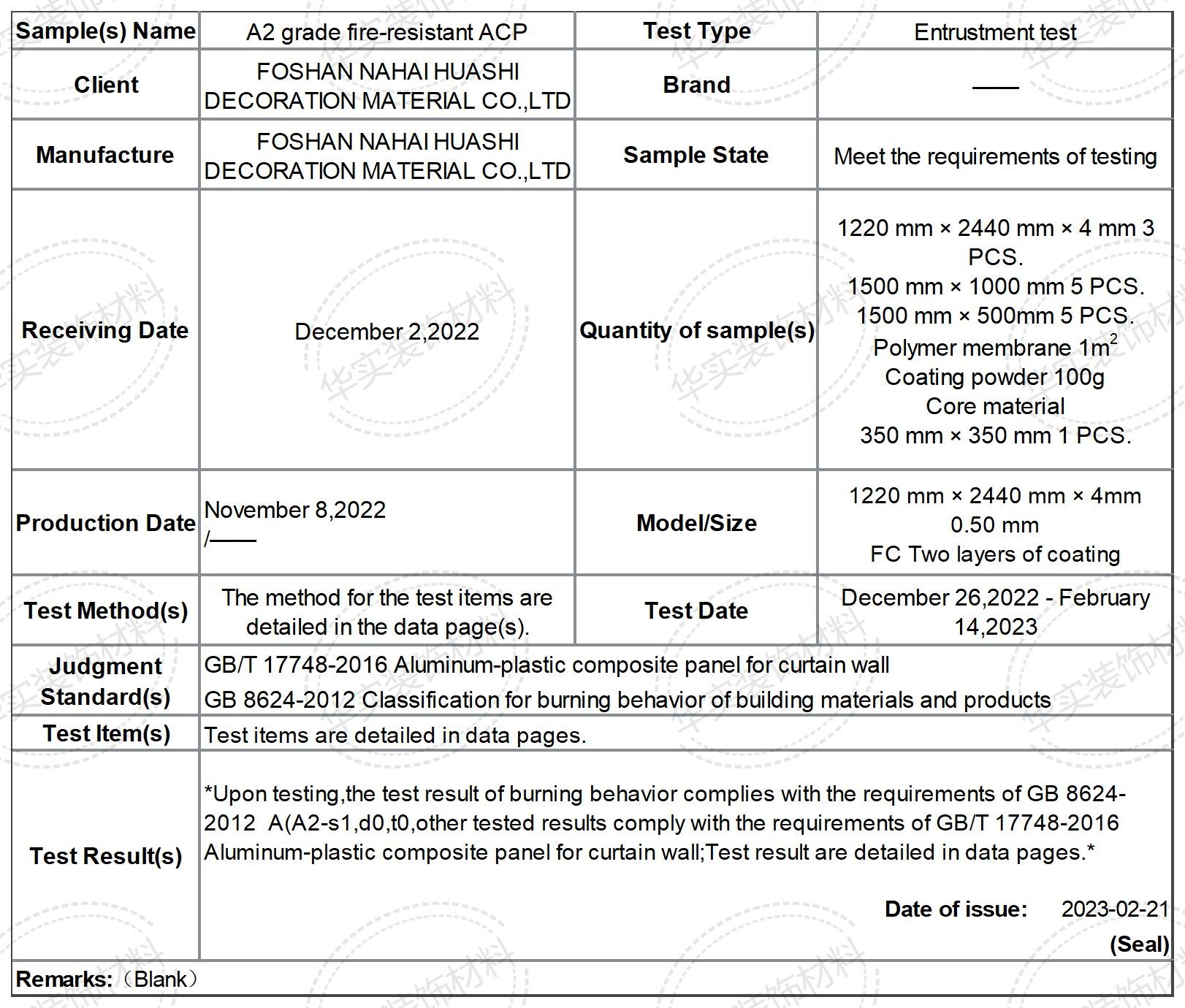

| Model Number: | A2 Fire Rated ACP Sheets |

| Certification: | ISO 9001:2008;GB/T 17748-2016;GB 8624-2012 |

| Place of Origin: | CHINA |

| MOQ: | 1000 sqm |

| Price: | depends on your needs |

| Payment Terms: | T/T |

| Delivery Time: | usually within 14 working days |

| Sheet thickness: | 2.0mm,3.0mm,4.0mm,5.0mm |

| Aluminum layer thickness: | 0.15mm,0.2mm,0.3mm,0.4mm, |

| Surface color: | High gloss,Stone grain,Mirror finish,Special effects |

| Application fields: | balcony,ceilings,partitions,column casings,equipment panels,interior decoration,interior design,furniture surfaces,Curtain walls,billboards,exhibitions,signs,signboard doors,coffee shop interior design,renovation of old buildings, |

| Surface coating: | Polyester (PE),High-performance polyester (HDPE),Fluorocarbon (PVDF),PVC film |

| Size: | 1220mm * 2440mm or Customizal |

| Packaging Details: | Stacked one by one, with fiberboard as cushion |

| Company Info. |

| Foshan Nanhai Huashi Decoration Material Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

0.15mm Aluminum Layer Fire Rated ACP Sheets, Customized, PE Coating, For Curtain Walls

DESCRIPTION

Regarded as aluminum composite panels, these are composite materials composed of two aluminum cover sheets and a non-aluminum core. The inherent properties of these panels, such as high rigidity, low weight, and resistance to weather, have rendered them a popular choice in sectors like architecture and signage. They can be manipulated into various forms and sizes, thereby enabling a high degree of design flexibility. In addition, aluminum plastic panels exhibit good thermal insulation and soundproofing qualities, hence their use in insulating building envelopes and noise barrier walls.

Company Profile

Company Profile

Founded in 1999, we have imported top-tier extrusion equipment to produce high-quality Aluminum Composite Panels. Our offerings beautify exteriors of offices, malls, and high-rises, while also enhancing interiors of luxury homes. Benefits include durability, aesthetics, and insulation. Recognized with various awards, we've also passed ISO 9001:2008 and are associated with key industry bodies. Our "Richly Bound" brand offers diverse decorative panels. We ensure quality, with products meeting national standards and being recommended by authorities. Located near Hong Kong, we invite global clients to collaborate.

Product Features

Product Features

1.Light-as-a-feather Construction: Aluminum-plastic panels, due to their light-as-a-feather

construction, are a favorite in the building and decorating sector.

Their lightness allows for easy installation and transportation,

leading to a reduction in construction expenses. Despite their

lightness, they remain sturdy and long-lasting.

2.Exceptional Weatherproof Qualities: With their exceptional weatherproof qualities, aluminum-plastic

panels can withstand harsh weather conditions, including intense

sunlight, wind, rain, humidity, and temperature variations. This

makes them an excellent choice for outdoor building and decorating

projects.

3.Multitude of Colors and Styles: Aluminum-plastic panels come in a multitude of colors and styles

to satisfy various aesthetic tastes. The surface of this material

can be manipulated in several ways, including spraying, coating,

and printing, to create distinctive visual aesthetics.

4.Low-maintenance and Easy to Clean: The surface of the aluminum-plastic panel is sleek and resistant

to dust and grime accumulation. Cleaning it is as simple as using a

detergent and cloth. This material requires no special maintenance

and can keep its original appearance and performance for a long

time.

5.Environmentally Conscious: Aluminum-plastic panels are an environmentally conscious material

that doesn't release harmful substances. Additionally, its

recyclability is a boon to environmental preservation.

6.Superior Soundproofing: Aluminum-plastic panels offer superior soundproofing, reducing

noise transmission. This makes them highly beneficial in places

where sound insulation is required, such as offices, hospitals, and

schools.

7.Fire-resistant: Aluminum-plastic panels have excellent fire resistance. In a fire,

they can prevent the spread of flames and protect the structural

safety of buildings.

Application fields

1.Urban Facades: Cladding solutions for towering structures, single-family homes,

enterprise buildings, and trade high-rises.

2.Inner Ambiance: Enhancing indoor aesthetics in residences, corporate spaces, and

marketplaces through wall installations, artful ceilings, and

separators.

3.Promotion Boards: For broad advertisements, business entrances, informational

indicators, digitally printed displays, and stage setups.

4.Transit Vehicles: Fabrication of parts for city buses, railway vehicles, metro

carriages and seafaring ships.

5.Domestic Decor: Craftsmanship in furniture pieces, storage closets, modular

kitchens, and decorative fittings.

6.Production Environments: Functional in workshops for machine safeguards, gear protection,

and sterile area settings.

7.Shopping Interiors: Conceptualizing retail interiors, service kiosks, and product

demonstration setups.

8.Accommodation Sector: Enhancements and displays in inns, holiday locations, dining

venues.

9.Health Centers: Claddings in health establishments, treatment facilities, for its

sanitary and long-lasting qualities.

10.Learning Spaces: Employed in pedagogical institutions, higher ed facilities for

informative displays, seating, and dividers.

11.Athletic Venues: Usage in arenas, training facilities, and sports hubs for

aesthetic finishes and directive displays.

12.Transit Points: Finishes and wayfinders in aviation points, rail centers,

passenger stations, and marine docks.

Product processing performance

Our range of aluminum composite panels can be adeptly modified with general carpentry and metallurgy equipment. Techniques such as lacerating, bisecting, etching, punching, condensing, pleating, and recurving are manageable. These ensure finesse in executing structural aesthetic mandates, notably patterns like helicals, anti-helicals, micro-angled terminuses, and varying vertexes. This pliability is rare in other decorative elements.

1.Partitioning: Equipments like manual blades, electric slicers, and loop cutters

are proficient.

2.Etch Milling: When maneuvered with a handheld etcher, a myriad of geometric

shapes can be hand-carved.

3.Apex Clipping: Through punch-tools and apex clippers, uniting in a structure is

streamlined.

4.Amalgamating: A blend using warm air instruments and resin welding threads is

possible.

5.Apex Curve: Successive to etch milling, it's feasible to mold multiple angles.

6.Spiraling: Trio-point or triple-roll devices are proficient for such tasks.

7.Stenciling: Imprint via stencil imprint methods.

8.Mounting: Engage mechanisms like bolts, pins, and self-piercing screws.

9.Stamping: Depressions are possible using an expansive puncher.

|