| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Vacuum Cleaner Motor |

|---|---|

| Brand Name: | Go-Gold |

| Model Number: | KG-2430DC24 |

| Certification: | ISO |

| Place of Origin: | China |

| MOQ: | 1000pcs |

| Price: | Negotiation |

| Payment Terms: | L/C, T/T, Paypal |

| Supply Ability: | 10000pcs-30days |

| Delivery Time: | 7days for samples |

| Packaging Details: | Paking in boxes |

| Max Efficiency Current: | 0.396A |

| Rated Voltage: | DC24V |

| Torque: | 324g.cm |

| Power: | 5.37W |

| No-load Speed: | 9737RPM |

| Efficiency: | Other |

| Company Info. |

| Shenzhen Go-Gold Motor Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

Lead Time

| Quantity(pcs) | 1-1000 | 1001-10000 | >10000 |

| Lead Time(days) | 15 | 30 | To be negotiation |

Motor Details

Warranty: 3years

Place of Origin: Guangdong, China

Brand Name: Go-Gold

Model Number: KG-2430DC24

Usage: Vacuum Cleaner

Torque: 324g.cm

Commutation: DC

Speed(RPM): 9737RPM

Continuous Current(A): 1.32A

Product Name: Vacuum Cleaner Motor BLDC Motor

Motor type: BLDC Motor

Certification: ISO

Rated Voltage: 24V/ Customized

Keywords: Vacuum Cleaner Motor

Noise: Low

Performance Specifications

| Rated Voltage | DC24V | Output Power | 5.37W |

| No-load Current | 0.09A | Torque | 324g.cm |

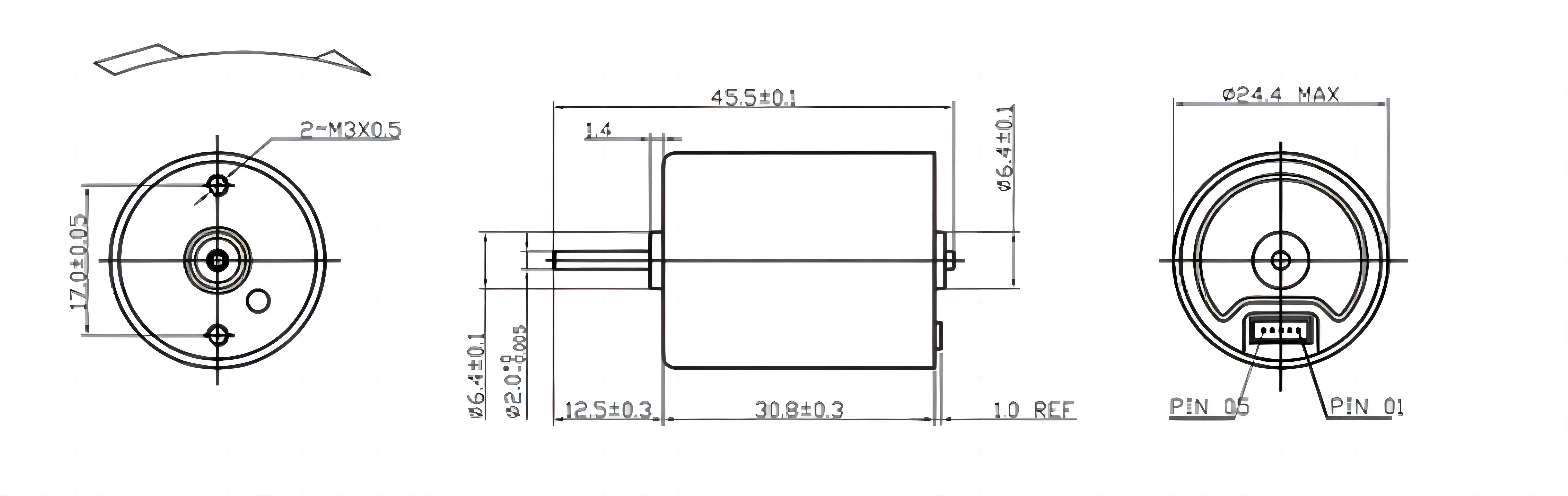

Drawings

Motor Application

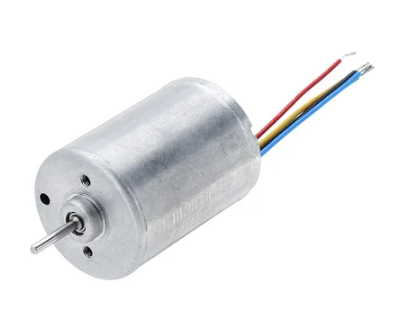

Motor Picture

The difference between Brushed DC Motor and BLDC Motor speed control methods

In fact, the control of both motors is voltage regulation, but because the brushless DC uses electronic commutation, it can only be realized with digital control, while the brushed DC commutates through carbon brushes, using thyristors, etc. Traditional analog circuits can be controlled and are relatively simple.

Types of BLDC Motor

For the inner rotor type, the rotating part is located inside the stator and the segmented permanent magnets are mounted on the outer surface of the rotor. Due to the small rotor diameter and small moment of inertia, it has good acceleration and deceleration response. In addition, since the stator is close to the motor surface and has good heat dissipation, a compact motor with high output power can be realized.

This is a typical BLDC Motor configuration and is used in a wide range of applications. In my opinion, they could save a lot of space or be an effective choice for material handling applications, such as driving pulleys on conveyor belts and/or moving the wheels of an AGV.

For the external rotor type, the rotor is located outside the stator and the permanent magnets are located inside the rotor. Segmented permanent magnets are mounted on the inner surface of the rotor. The position of the stator and permanent magnets is opposite to that of the inner rotor type. The cup-shaped rotor has a large inertia moment and poor acceleration and deceleration response, making it unsuitable for flexible movement, but it can still provide good speed stability.

Due to the larger rotor diameter, more magnets can be installed compared to the inner rotor type, and the number of poles is increased compared to the inner rotor type. This makes it possible to achieve high output power in a compact size. However, since the winding is located inside and has poor heat dissipation, the winding easily generates heat, which limits the working time. In drone motors with external rotor brushless motors, the rotor cup has ventilation holes, and the wind generated by the spiral helps keep the windings cool.

The application range of the external rotor type is narrow. The rotor's large inertia makes quick starts and stops more difficult. Poor cooling limits working time. However, if the motor is designed with thermal ventilation, radiation or cooling in mind, applications can extend to cooling fans and drones, among others.

For disc rotor types, the stator is formed by mounting windings and pole sensors on a circuit board. This type of motor is very thin because the plate permanent magnets are located on the surface of the rotor, facing the stator. It is used to maintain a stable and fixed speed under light loads. There is no shaft, so the load is mounted on the rotor.

This type of motor is commonly used in hard drives and disk drives for CVD, Blu-ray Disc, and other media, but it can be expanded to other applications where space is limited.

|