| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | DTF Hot Melt Powder |

|---|---|

| Brand Name: | Tunsing |

| Model Number: | DS220 |

| Certification: | RoHs, REACH |

| Place of Origin: | China |

| MOQ: | 1kg, 2kg, 5kg 20kg, |

| Price: | 4.5-6dollar per kg |

| Payment Terms: | T/T, PayPal |

| Supply Ability: | 6000kg per day |

| Delivery Time: | 5-7days |

| Packaging Details: | 1kg per bag, 5kg per bag, 20kg per bag |

| Appearance: | White powder |

| Density ASTM D-792: | 1.20±0.02 g/cm³ |

| Melt Point DSC: | 95-115 ℃ |

| Melt Index ASTM D-1238: | 30±7 g/10min |

| Hardness: | 80±3 Shore A |

| Powder size range: | 80-200 μm,150-250 μm |

| Company Info. |

| Shenzhen Tunsing Plastic Products Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

Heat Transfer TPU Polyurethane Powder Hot Melt DTF Adhesive Powder

DTF Hot Melt Powder Description

DTF Powder Product model: DS220

Material: PET film is a transparent or translucent plastic film made from polyethylene terephthalate. It is known for its excellent mechanical properties, such as high tensile strength, dimensional stability, and resistance to moisture and chemicals.

Size and Thickness: DTF PET film rolls are available in various sizes and thicknesses. The size of the roll can vary depending on the specific requirements of the DTF printing system, such as the width of the printer or heat press machine. The thickness of the PET film typically ranges from 75 to 125 microns (0.075 to 0.125 mm), but other options may be available.

Heat Resistance: PET film has good heat resistance, which is important during the heat transfer process in DTF printing. It can withstand the high temperatures required for activating the adhesive layer of the DTF powder and ensuring proper adhesion to the fabric or substrate.

Adhesive Compatibility: DTF PET film rolls are designed to be compatible with the adhesive properties of DTF printing powders, such as TPU (Thermoplastic Polyurethane) powder. The adhesive layer of the DTF powder adheres to the PET film during the printing process and is later transferred onto the fabric or substrate.

Transparency and Registration: PET film is typically transparent or translucent, allowing for easy alignment and registration of the printed design with the fabric or substrate. This transparency ensures accurate placement of the design, resulting in precise and visually appealing prints.

DTF TPU Powder Physical Characteristics:

| Property | Criterion |

| Appearance | White powder |

| Composition | TPU |

| Density ASTM D-792 | 1.20±0.02 g/cm³ |

| Melting Point DSC | 95-115 ℃ |

| Melt Index ASTM D-1238 | 30±7 g/10min |

| Hardness | 80±3 Shore A |

| Powder size range | 0-80 um,80-200um,150-250um |

| Resistance to yellowing (level) | 2.0-3.0 |

DTF Powder Application:

DS220 is used in clothing, luggage, shoe materials and heat

transfer industries.

DTF Powder Technical Parameters:

Bonding Parameters ( reference only) | Temperature | 110-130℃ |

| Press | 1.5-2.5 kg/cm2 | |

| Time | 8-15 S | |

| Washing Resistance | 40℃ | Excellent |

| 60℃ | Good | |

| 90℃ | / |

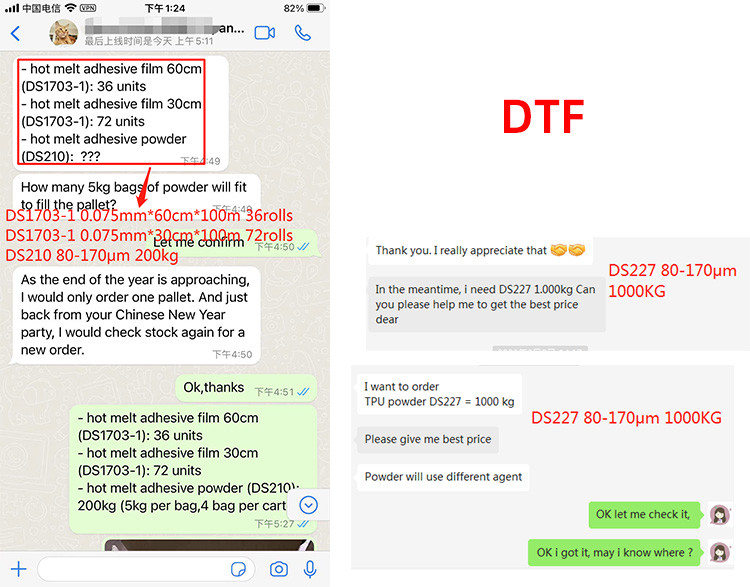

DTF powder Customer feedback

|