| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

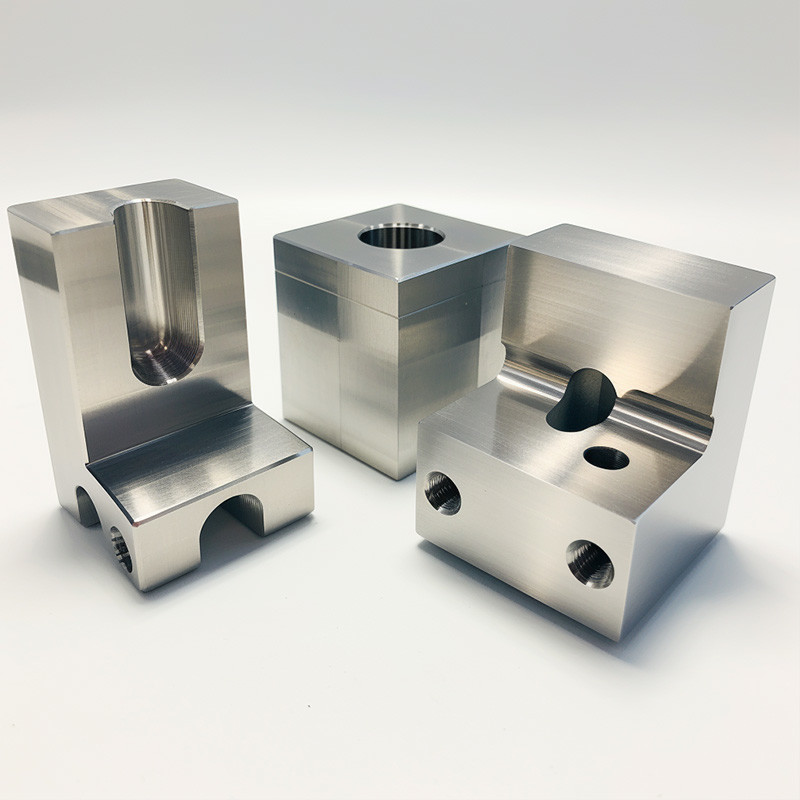

| Categories | Precision CNC Machining Parts |

|---|---|

| Brand Name: | Yexin |

| Model Number: | SM53 |

| Certification: | ISO9001:2015 |

| Place of Origin: | Dongguan, China |

| MOQ: | 1 pcs |

| Price: | Negotiable |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union |

| Supply Ability: | 125000 pcs/month |

| Delivery Time: | 2-13 work days |

| Packaging Details: | Standard Export Carton, Wooden Case, etc. |

| Application: | Medical, Construction, Agriculture, Aerospace, Manufacturing, Automotive, etc. |

| Color: | Customized |

| Material: | Aluminum, Stainless Steel, Brass, Plastic, Wood, Copper, etc. |

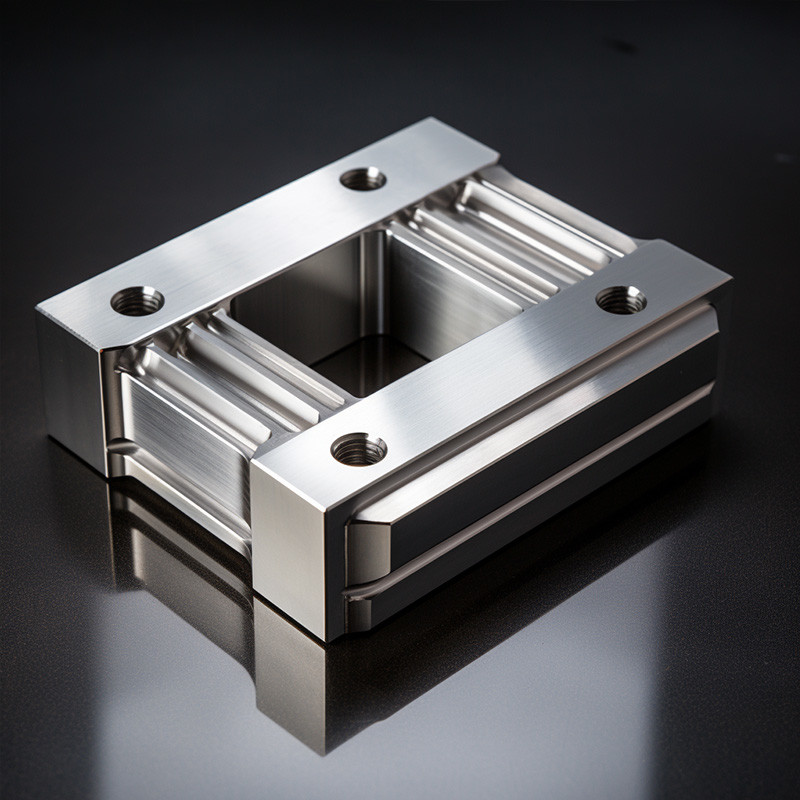

| Processing: | CNC Turning, CNC Milling, CNC Drilling, etc. |

| Service: | OEM, ODM, Customized |

| Surface Finish: | Polishing, Painting, Anodizing, etc. |

| Tolerance: | ±0.01mm-0.005mm, etc. |

| Drawing Format: | PDF, CAD, STEP, STP, IGES, IGS, SLDPRT, 3DM, SAT, etc. |

| Keyword: | Precision CNC Machining Parts |

| Company Info. |

| Dongguan Yexin Intelligent Technology Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

The process of our custom CNC machining service involves leveraging the predominant subtractive

manufacturing technology of CNC machining. This method is particularly effective in crafting bespoke

metal and plastic parts for both prototyping and production needs.

Through the utilization of CAD modeling software and G-code, CNC milling and CNC turning

machines meticulously remove material from solid workpieces with precision and efficiency.

Our service excels in delivering sturdy components with stringent tolerances and diverse material

properties, both mechanical and chemical. Its applicability extends seamlessly to one-off projects

and low-to-medium volume production, facilitated by automation and high repeatability.

Product Details

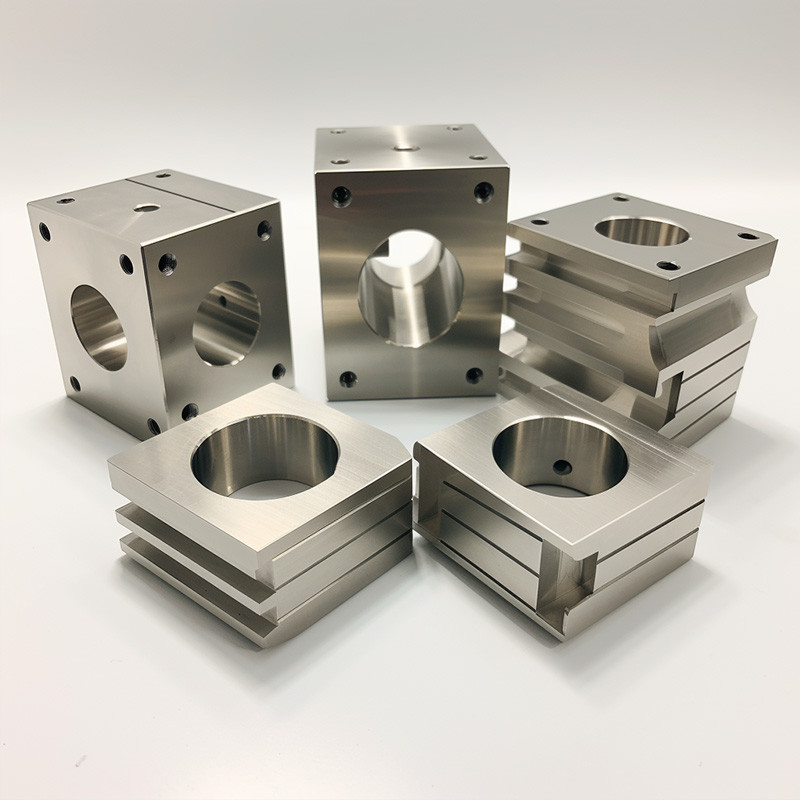

CNC machining tools are capable of precisely cutting an extensive range of materials, including

aluminum, bronze, copper, ceramics, plywood, diverse steel types, stone, wood, zinc, and other

engineering materials.

This broad applicability renders them well-suited for crafting prototypes in product development.

Additionally, the machinery allows for meticulous and swift adjustments, ensuring the final product

meets the desired specifications.

| Common Materials | |

| Name | Description |

Aluminum | High machinability and ductility, good strength-to-weight ratio. |

Stainless steel | High tensile strength, corrosion and temperature resistant. |

Mild steel | High machinability and weldability, high stiffness. |

Brass | Low friction, excellent electrical conductivity, golden appearance. |

Copper | Excellent thermal and electrical conductivity. |

Titanium | Excellent strength to weight ratio, used in aerospace, automotive and medical industries. |

ABS | Common thermoplastic, impact resistant, easy to machine. |

| Surface Finishes | ||

| Name | Applicable to | Machining marks |

| As machined | Metals, Plastics | Visible, light surface scratches |

| Smooth machining | ||

| Fine machining | Metals | Slightly visible |

| Polishing | Metals | Removed on primary surfaces |

| Bead blasting | Metals | Removed for non-cosmetic, removed on primary surfaces for cosmetic |

| Brushing | Metals | |

| Anodizing Type II | Aluminum | |

| Anodizing Type III | Aluminum | Visible under anodizing |

| Black oxide | Copper, Stainless steel, Alloy steel, Tool steel, Mild steel | Visible |

| Powder coating | Metals | Removed |

| Brushed + electropolishing | Stainless steel | Removed on Primary surfaces |

Specialist Industries

CNC machining, being a versatile subtractive manufacturing process, finds extensive application

across a multitude of industries. Some of the key sectors that heavily rely on CNC machining include:

1. Aerospace: Precision is paramount in aerospace, and CNC

machining is instrumental in crafting

intricate components for aircraft and spacecraft, ensuring optimal performance and safety.

2. Automotive: The automotive industry utilizes CNC machining for

the production of precise and

complex parts, ranging from engine components to intricate systems, contributing to the efficiency

and reliability of vehicles.

3. Aviation: Similar to aerospace, the aviation industry benefits

significantly from CNC machining,

ensuring the manufacturing of high-precision components for aircraft to meet stringent safety and

performance standards.

4. Transportation: Beyond aerospace and automotive, the broader

transportation sector, including

rail and maritime industries, relies on CNC machining for the fabrication of critical components that

withstand rigorous operational demands.

These industries highlight just a few examples of CNC machining's

widespread utilization.

The technology's ability to deliver accuracy, consistency, and intricate detailing makes it indispensable

in various integral sectors, ensuring the production of high-quality components that meet the

stringent standards of modern manufacturing.

Company Profile

FAQ's

1. A quick guide to CNC machining parameters

Most machining parameters are established by the machine operator during the generation

of G-code.

Build Size of CNC Machines:

CNC machines offer a notably large build area, especially when

compared to 3D printers.

CNC milling systems can handle parts with dimensions up to 2,000 x

800 x 100 mm

(78” x 32” x 40”).

CNC turning systems can machine parts with a diameter of up to Ø

500 mm (Ø 20’’).

Accuracy and Tolerances:

CNC machining enables the production of parts with high accuracy

and tight tolerances.

Tolerances achievable with CNC machines can be less than half the

diameter of an average human

hair, reaching ± 0.025 mm or .001’’.

If tolerance is not specified in the technical drawing, the

operator typically machines the part with

an accuracy of 0.125 mm (.005’’).

Key Takeaways:

CNC machines excel in both build size and precision, making them suitable for a wide range of

applications.Operators have the flexibility to set machining parameters based on the specific

requirements of the project.

Understanding the build size and achievable tolerances is crucial

for designing parts that meet

precision and accuracy standards.

2. How much do CNC machining materials cost?

CNC machining offers a plethora of material choices, leading to varying costs across different options.

The price range for materials is broad, influenced by factors such as physical properties and specific

characteristics of each material.

For metal parts, Aluminum 6061 stands out as the most economical choice. If cost is a primary

consideration, ABS emerges as the most budget-friendly option.

Additionally, the ease of machining significantly impacts costs, with materials like stainless steel posing

a higher machining difficulty compared to aluminum, thereby contributing to an increased overall cost.

3. What's the general surface texture of CNC milled and turned parts?

Typically, machined milled parts exhibit a surface roughness of around 3.2μm (or 1.6μm for newer

machines). On the other hand, turned parts can achieve a finer surface with a roughness of 0.8μm.

This indicates that the machining speed does not necessarily need adjustment, highlighting the

precision attainable in turning processes.

|