| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Insert Molding Plastic Filters |

|---|---|

| Brand Name: | Share Filters |

| Model Number: | Dental Suction Separator Filter |

| Certification: | SGS |

| Place of Origin: | China |

| MOQ: | 1000pcs |

| Price: | USD0.05-USD2.00/pc |

| Payment Terms: | T/T, L/C, Western Union, MoneyGram, PayPal |

| Supply Ability: | 10000pcs/day |

| Delivery Time: | 7-20 days |

| Packaging Details: | Caron, Polybag |

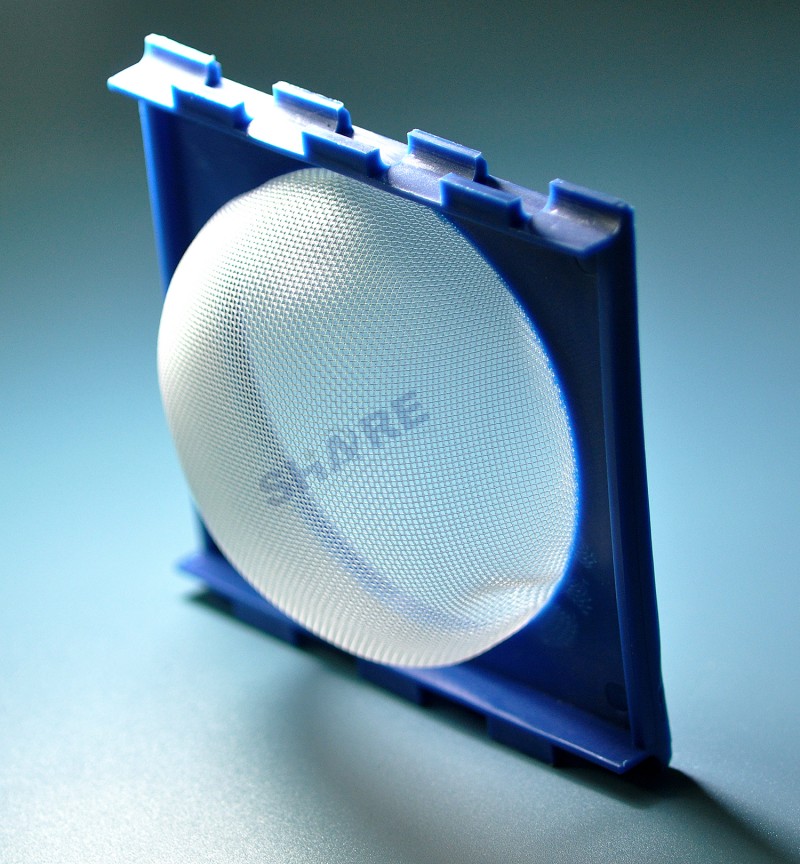

| Product Name: | Dental suction system separator filter |

| Keyword: | Dental equipment filter |

| Rim material: | PA, PP,PET, ABS, POM, PE, etc. |

| Filter Media: | Nylon mesh, polyester mesh |

| Micron Rating: | 200μm-600μm |

| Colour: | Yellow, white, black, customised |

| Company Info. |

| Share Group Limited |

| Verified Supplier |

| View Contact Details |

| Product List |

Custom Disposable Separator Water Filter For Suction Systems Of Dental Equipment

Share Filters' dental suction system separator water filter combines the nylon or polyester filter mesh with plastic, allowing for a more robust part giving more reliability and longevity in its use. Injection moulding can take many forms and Share Filters is fully capable to help develop and produce the injection moulded filter products according your drawing that will best suit your needs, as well as, offering any additional advice or service along the way.

Share Filters Dental Suction System Separator Filter Material Options

| Support rim material | PA, PET, PP, PC ABS, PE, POM, etc. |

| Filter media | Nylon mesh, polyester mesh, PP mesh, metallic mesh | |

| Micron rating | 20μm - 500μm | |

| Mesh parts fabrication | Laser cutting, sonic cutting, sonic welding, heat welding |

| Process | Mesh insert injection moulding | |

| Specification | Custom | |

| Colour | Custom |

Nylon Filter Mesh Specification For Dental Suction System Separator Filter

| Fabric number | Mest count | Thread diameter | Mesh opening | Open surface | Fabric thickness | Weight | |

| No. | mesh/cm | mesh/inch | micron | micron | % | micron | g/m2 |

| JPP12 | 12 | 30 | 250 | 583 | 49 | 470 | 162 |

| JPP12 | 12 | 30 | 300 | 533 | 41 | 585 | 234 |

| JPP14 | 14 | 35 | 300 | 414 | 34 | 595 | 273 |

| JPP16 | 16 | 40 | 200 | 425 | 46 | 370 | 139 |

| JPP16 | 16 | 40 | 250 | 375 | 36 | 485 | 217 |

| JPP20 | 20 | 50 | 150 | 350 | 49 | 375 | 98 |

| JPP20 | 20 | 50 | 200 | 300 | 36 | 385 | 173 |

| JPP24 | 24 | 60 | 150 | 267 | 41 | 285 | 117 |

| JPP28 | 28 | 70 | 120 | 237 | 44 | 215 | 87 |

| JPP30 | 30 | 76 | 120 | 213 | 41 | 225 | 94 |

| JPP32 | 32 | 80 | 100 | 213 | 46 | 165 | 69 |

How To Select The Filter Mesh?

You can follow these points.

Share Filters OEM Plastic Moulded Filters

Why Work With Share Filters ?

Share Filters specializes in helping our customers design and manufacture high quality mesh filter components to around the world. As a supplier combining the woven filter mesh manufacturing and mesh processing according to custom-made design, we are flexible enough to adapt to our customers’ production and delivery needs. Our advanced manufacturing processes and scientific machines allow us to create filtration products in any shape or configuration – from simple, traditional components like mesh shapes to highly complex devices like custom plastic filters.

Our customers typically work in the fields of food technology, motor equipment, water treatment, healthcare, semiconductor technology, automotive, medicine and pharmaceuticals. We also supply institutes, laboratory facilities or private end custom

Share Filters Factory Capabilities

| Synthetic Mesh | Slitting | Cutting | Welding | Sewing | Injection Moulding |

|  |  |  |  |  |

| Share Filters synthetic meshes can be made from a variety of materials such as polyamide, polyester, polypropylene, etc. You can order by the roll or cut shape. | Ultrasonic slitting is also used for manufacturing mesh strips and produces a closed edge with very little material build up at the edge. | Our cutting method include Laser cutting, cold cutting, heat cutting, slitting, stamping. professional cutting using custom made tools that will not damage the meshes. | Sonic welding are accurate, clean. Precision sleeves and bags for blood filtration, rosin bag for rosin press are examples of applications that benefit from this technology. | Share Filters sewing products are carried out by highly skilled and experienced machinists, which ensure you get the right level of consistent quality. | Custom plastic molded filters combine precise filter mesh with plastic. Industry serve: Automotive, Appliances, Food and beverage, Medical, Life Science and Laboratory. |

Photos of Share Filters Workshops

If you want a mesh insert filters manufacturing partner capable of providing you with the experience support system, look no further than Taizhou Share Filters Co., Ltd.

Contact us

Taizhou Share Filters Co., Ltd.

Pingqiao Industrial Park

Tiantai County, Zhejiang Province,China

Tel/WhatsApp: +8615858692620

Email: sales02@sharefilters.com

|