| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Multihead Weigher Packing Machine |

|---|---|

| Brand Name: | TOUPACK |

| Certification: | CE,ISO9001 |

| Place of Origin: | China |

| MOQ: | 1 set |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 30 sets/month |

| Delivery Time: | According to the actual situation |

| Packaging Details: | Wooden case |

| Hopper Surface: | Plain plate hopper / Dimple plate hopper |

| After-sales Service Provided: | Online support |

| Material: | Stainless Steel 304/316 |

| Key Selling Points: | High-accuracy |

| Customized support: | OEM,ODM |

| Function: | Waterproof |

| Parameter Adjustment: | Auto learning/Manual setting |

| Option: | imple Plate/Timing Hopper/Diverter device/ Printer/Rotary Top Cone |

| Company Info. |

| GUANGDONG TOUPACK INTELLIGENT EQUIPMENT CO., LTD |

| Verified Supplier |

| View Contact Details |

| Product List |

Automatic 5kg Cat Litter Zipper Bag Packing Machine Premade Pouch Packaging Machine

Max. Weighing (one hopper) | 100-3000g |

Accuracy | x (0.1) |

Min. Scale Interval | 0.1g |

Max. Speed | 60 BPM |

Hopper Volume | 5.0L / 7.5L |

Control System | MCU / PLC |

Main Function & Features:

1. Professional digital weighing module with high precision and good stability

2. Control system: MCU or PLC (optional).

3. Touch screen interface with different levels of authorized access; up to 16 different languages for choice; application software upgraded through USB.

4. Factory parameters recovery function; 99 preset product parameters to meet different parameter program requirements.

5. Weighing hopper able to discharge in turn to effectively prevent products from blocking.

6. Weighing and counting function to meet diverse needs from customers.

7. Real-time display of amplitude of each vibration pan as well as product weight in each hopper to better monitor the running status of the machine.

8. Machine body with SUS304/316 for option and IP65 dust and waterproof design.

Solution:

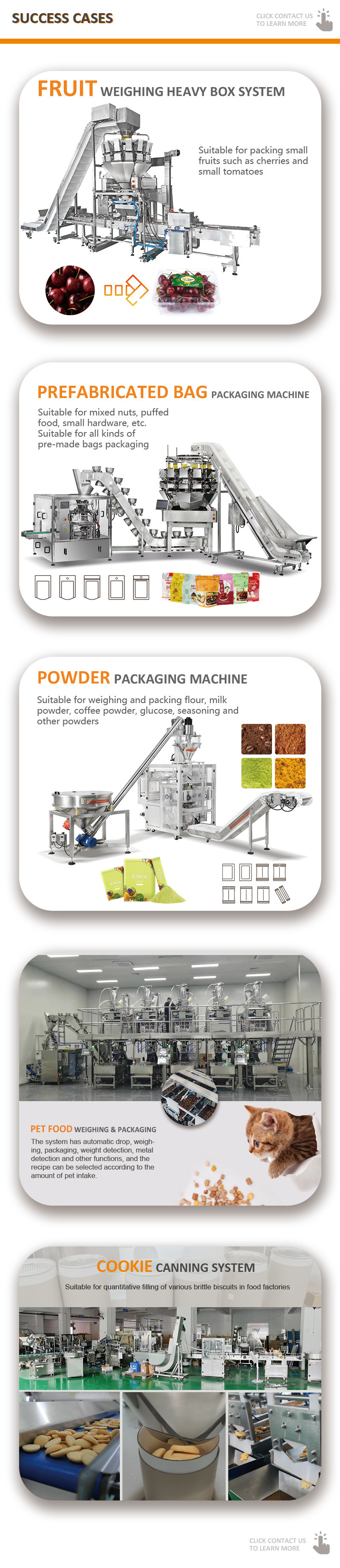

According to your production line requirements, our experts will provide you with an integrated weighing and packaging solution to help you improve production efficiency.

|