Smart Wearables Applicable T-core Integrated Inductor Winding

Machine IOS9001 Approved

Product Description:

The Xingte T-core winding machine is specifically designed for use

in T-core inductor production lines to assist with coil winding.

Our XT-M01 model features a cutting-edge high-speed winding mode

that incorporates optical PLC automation technology. This T-core

winding machine offers exceptional precision, speed, and

productivity.

Features:

Multi-model matching:

T-core winding machines can be matched with a variety of assembly

line production machines including

1210/1608/2012/2016/2520/0303/0404, and can be customized for

matching.

High stability:

The T-core winding machine uses purely imported hardware to ensure

product operation stability and has a yield rate of 99.9% and an

cycle time of 2~4s, effectively ensuring the stability and

reliability of production.

Multiple styles of winding:

The T-core winding machine is different from conventional coil

winding machines. It adopts a switchable time winding unit, which

can perform vertical winding/horizontal winding, even/odd turns,

round wire/flat wire and other forms.

The advantages of high precision, high speed, high yield, and high

quality can effectively help customers improve stable production

capacity.

Feeding:

The vibrating plate is used to realize fully automatic feeding, and

the plate is designed with automatic screening and scrap removal

functions;

Wire feeding:

It adopts digital display adjustable automatic wire feeding

tensioner to monitor the wire feeding tension in real time, and the

system controls the tension range to provide guarantee for winding;

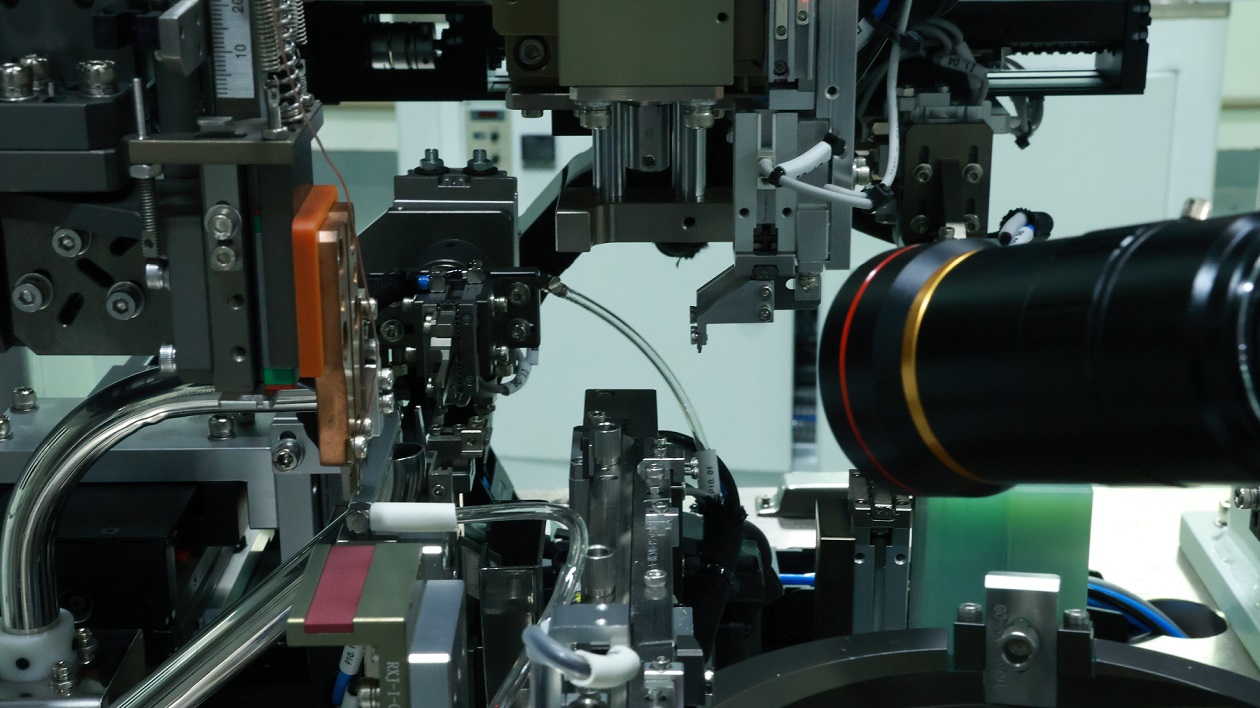

Wire winding molding:

Independently developed integrated modules for picking up

materials, clamping wires, and winding wires. The two axes are

wound at the same time. It can also be wound with different numbers

of turns according to different products or different copper wires;

Cutting and spot welding:

Independently developed integrated module for turning, cutting and

spot welding, easy to adjust, corresponding positions and

parameters can be adjusted according to different products, no need

for frequent adjustments and debugging.

Technical Parameters:

| Technical Parameters | Value |

|---|

| Air Pressure | 0.4-0.6Mpa |

| Yield Rate | > 99% |

| Winding Direction | Clockwise/ Counterclockwise |

| After-sales Service Provided | Engineers Available To Service Machinery Overseas, Online Video

Technical Support |

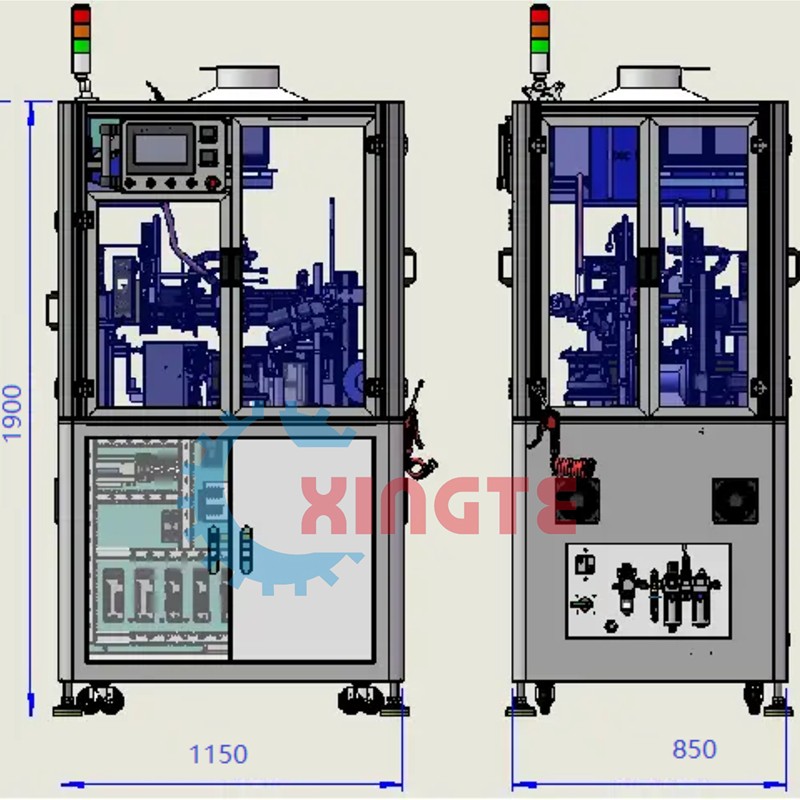

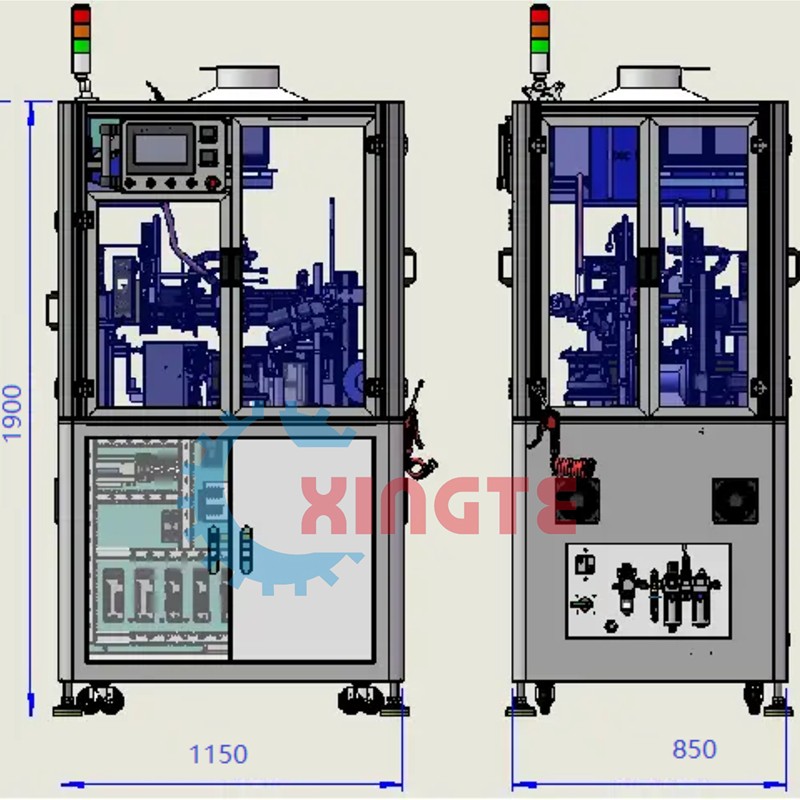

| Dimensions | 1150*850*1900mm |

| Applicable Product Type | 1608, 2012,2016, 2520, 3225 Type |

| Cycle Time | 2-4S/Pc |

| Operating Rate | >85% |

| Power | 3KW |

| Operation Voltage | 220v 50/60HZ |

| Product Type | High Precision T-Core Winding Machine, High Precision T-Core

Winding Machine, Automatic T-Core Winding Machine |

Applications:

Applications for T-core Type Small-Size Molded Inductors Production

Line

This production line specializes in manufacturing T-core type

small-size molded inductors for a wide range of applications,

including but not limited to computers, smartphones, smart

wearables, automobiles, and other fields. These inductors come in

various sizes, such as 1608, 2012, 2016, 2520, and 3225, to cater

to different product types.

With their compact size and reliable performance, these molded

inductors are essential components in electronic devices and play a

crucial role in ensuring their functionality. They are capable of

handling high currents and have low resistance, making them

suitable for use in a variety of industries.

Customization:

XINGTE Transformer Winding Machine - Customized Service

Brand Name: XINGTE

Model Number: XT-M01

Place of Origin: Shenzhen

Certification: CE, IOS9001, KC, ISO45001, ISO24001

Minimum Order Quantity: 1

Price: Negotiate

Packaging Details: Wooden case

Delivery Time: 10-25 working days

Payment Terms: LC,T/T

Supply Ability: 2000PCS/MONTH

Control Method: Automatic

Operation Voltage: 220v 50/60HZ

Dimensions: 1150*850*1900mm

Type: Automatic

Introducing the XINGTE Transformer Winding Machine - the ultimate

solution for all your T-core inductor winding needs. This

customized service is designed and manufactured by XINGTE in

Shenzhen, guaranteeing top-quality and efficient performance.

Equipped with the latest technology and advanced control methods,

our T-core Inductor Winding Machine offers automatic winding for

fast and accurate production. With a compact and sturdy design, it

is perfect for industrial use and can handle high volume

production.

Our Transformer Winding Machine is certified with CE, IOS9001, KC,

ISO45001, and ISO24001, ensuring its safety and quality standards.

The minimum order quantity is 1 unit, and the price is negotiable

based on your specific requirements.

For packaging, we use wooden cases to ensure the safe delivery of

your machine. The delivery time is 10-25 working days, and we

accept payment through LC or T/T.

With a monthly supply ability of 2000PCS, we are confident in

meeting your production needs. The operation voltage is 220v

50/60HZ, and the dimensions of the machine are 1150*850*1900mm.

Choose the XINGTE Transformer Winding Machine for efficient and

precise winding of T-core inductors. Contact us now to discuss your

customization options and get a quote.

Our company factory

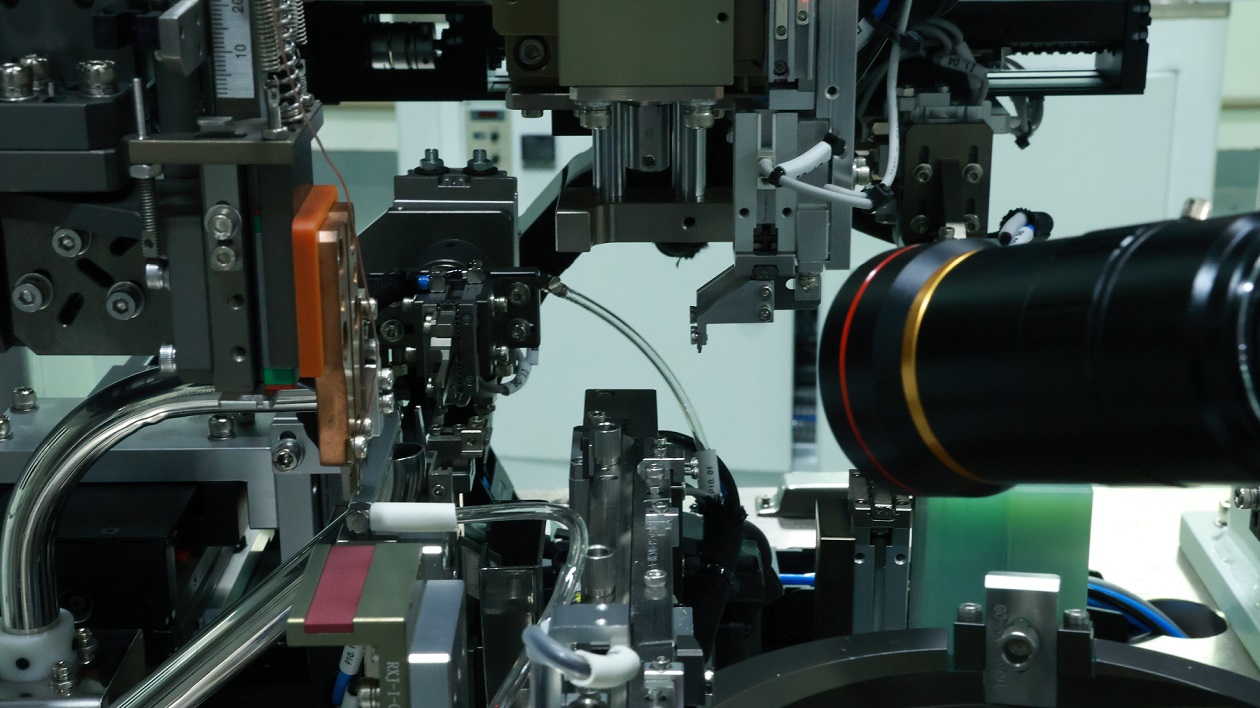

The T-core Integrated Inductor Winding Machine pictures

The sample pictures of T-core inductors

Xingte reliable partners

FAQ:

- Q: What is the brand name of this product?

A: The brand name of this product is XINGTE. - Q: What is the model number of this product?

A: The model number of this product is XT-M01. - Q: Where is this product manufactured?

A: This product is manufactured in Shenzhen. - Q: What certifications does this product have?

A: This product is certified by CE,IOS9001,KC,ISO45001,ISO24001. - Q: What is the minimum order quantity for this product?

A: The minimum order quantity for this product is 1. - Q: Is the price of this product negotiable?

A: Yes, the price of this product is negotiable. - Q: How is this product packaged for delivery?

A: This product is packaged in wooden cases for delivery. - Q: What is the estimated delivery time for this product?

A: The estimated delivery time for this product is 10-25 working

days. - Q: What are the payment terms for this product?

A: The payment terms for this product are LC and T/T. - Q: What is the supply ability of this product?

A: The supply ability of this product is 2000PCS per month.