| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Excavator Bucket Bushings |

|---|---|

| Place of Origin: | China |

| Packaging Details: | Plastic packaging |

| Supply Ability: | 2000 Piece/Pieces per Day |

| MOQ: | 100 pieces |

| Price: | $0.80/pieces 100-499 pieces |

| Applicable Industries: | Building Material Shops, Machinery Repair Shops, Manufacturing Plant, Food & Beverage Factory, Farms, Home Use, Retail, Printing Shops, Construction works , Energy & Mining, Other, Advertising Company |

| Showroom Location: | Egypt, Canada, Turkey, United Kingdom, United States, Italy, France, Germany, Viet Nam, Philippines, Brazil, Peru, Saudi Arabia, Indonesia, Pakistan, India, Russia, Spain, Thailand, Morocco, Kenya, South Korea, Chile, UAE, Colombia, Algeria, Romania, Bangl |

| Video outgoing-inspection: | Provided |

| Machinery Test Report: | Provided |

| Marketing Type: | New Product 2020 |

| Warranty: | Unavailable |

| Product name: | Bushing |

| Size: | Customized Size |

| Bush types: | Flange |

| Application: | Industrial Equipment |

| Features: | Wear Resistance |

| Lubricating: | Carbon |

| Product Material: | Steel+Porous Bronze+PTFE |

| Standard: | DIN1494 |

| Surface treatment: | Phosphating Black |

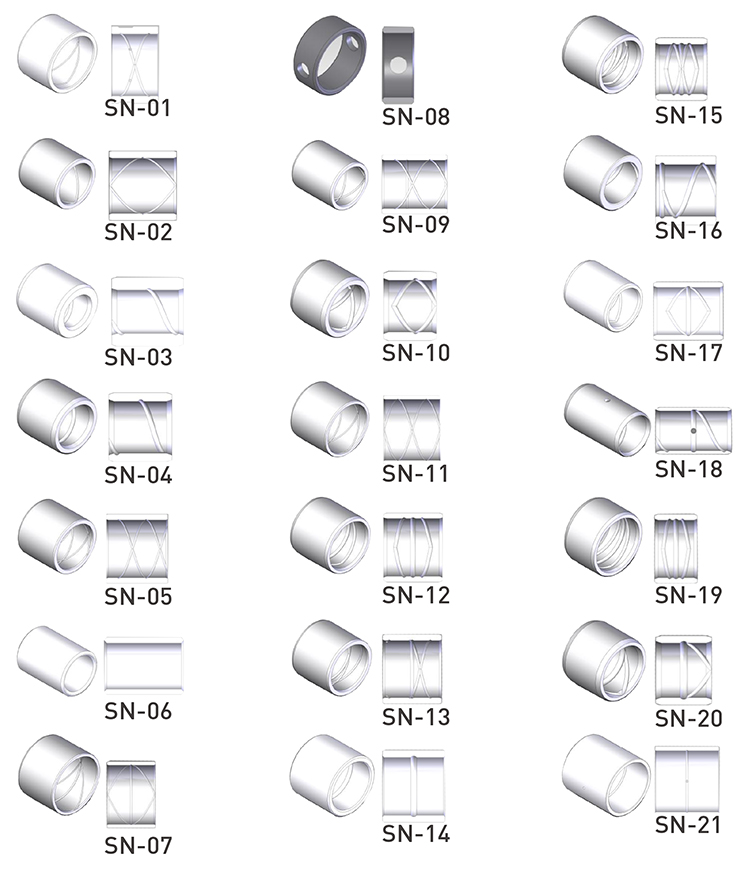

| Product Shape: | Customized Bushing |

| Port: | Qingdao |

| Company Info. |

| Guangzhou Quanhang Construction Machinery Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

High Load-Bearing Capacity Heat Treated Hardened Steel Bushing With Oil Sleeve Excavator Bushing

Excavator boom bushings are important components of an excavator's boom assembly. They serve as a cushioning and support mechanism, allowing the boom to pivot and rotate smoothly.

The excavator boom bushings are typically made from high-quality materials such as hardened steel or bronze. They are designed to withstand heavy loads, extreme temperatures, and wear and tear from repetitive movements.

These bushings are installed in the pivot points of the boom assembly, allowing it to articulate and extend. They reduce friction and prevent metal-to-metal contact, which helps to prolong the lifespan of other boom components.

Regular maintenance and lubrication of excavator boom bushings are essential to ensure smooth operation and prevent premature wear. Over time, these bushings may wear out and require replacement. Signs of worn-out bushings can include increased noise, reduced range of motion, and instability in the boom's movement.

Performance Index | Data | ||

Hardness | HRC | 58-62 | |

Max Load | N/mm2 | 250 | |

Max Linear Velocity | m/s | 0.1 | |

Max PV Value | N/mm2.m/s | 1.5 | |

WorkingTemperature Limit | ℃ | -100~ +350 | |

Linear Expension Coefficient | 10-5/℃ | 1.1 | |

Performance Index | Data | ||

Hardness | HV | ≥650 | |

Max Load | N/mm2 | 200 | |

Max Linear Velocity | m/s | 0.1 | |

Max PV Value | N/mm2.m/s | 1.5 | |

WorkingTemperature Limit | ℃ | -100~ +350 | |

Linear Expension Coefficient | 10-5/℃ | 1.1 | |

Performance Index | Data | ||

Hardness | HV | ≥650 | |

Max Load | N/mm2 | 200 | |

Max Linear Velocity | m/s | 0.1 | |

Max PV Value | N/mm2.m/s | 1.5 | |

WorkingTemperature Limit | ℃ | -100~ +350 | |

Linear Expension Coefficient | 10-5/℃ | 1.1 | |

Material and bushing characteristics | value | Company | value | ||

Maximum load | Mpa | 100 | psi | 145,00 | |

working temperature | ℃ | -40 to 300 | °F | -40 to 572 | |

Max Linear Velocity | m/s | 0.5 | fpm | 100 | |

Maximum PV Value | m/sxMPa | 1.65 | pis x fpm | 48,000 | |

Minimum hardness of sliding layer | HB | 210 | HB | 210 | |

Minimum hardness of dual parts | HRC | 40 | HRC | 40 | |

|