| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Pre Engineered Building |

|---|---|

| Brand Name: | XGZ |

| Model Number: | XGZ-PEB007 |

| Certification: | CE EN1090,ISO9001 |

| Place of Origin: | Pingdu,Qingdao |

| MOQ: | 100 square meters |

| Price: | USD 40-90 per square meter/Negotiable |

| Payment Terms: | T/T, L/C, Western Union, MoneyGram |

| Supply Ability: | 15000 tons per month |

| Delivery Time: | 30-55 days |

| Packaging Details: | Steel pallet or in bulk |

| Name: | Pre-engineered Building |

| Standard: | International Standard |

| Type: | Light |

| Application: | Pre-engineered Warehouse, Workshop Building |

| Size: | According to Customer Requirement |

| Surface Treatment: | Painting or Galvanized |

| Color: | Customers' Requirement |

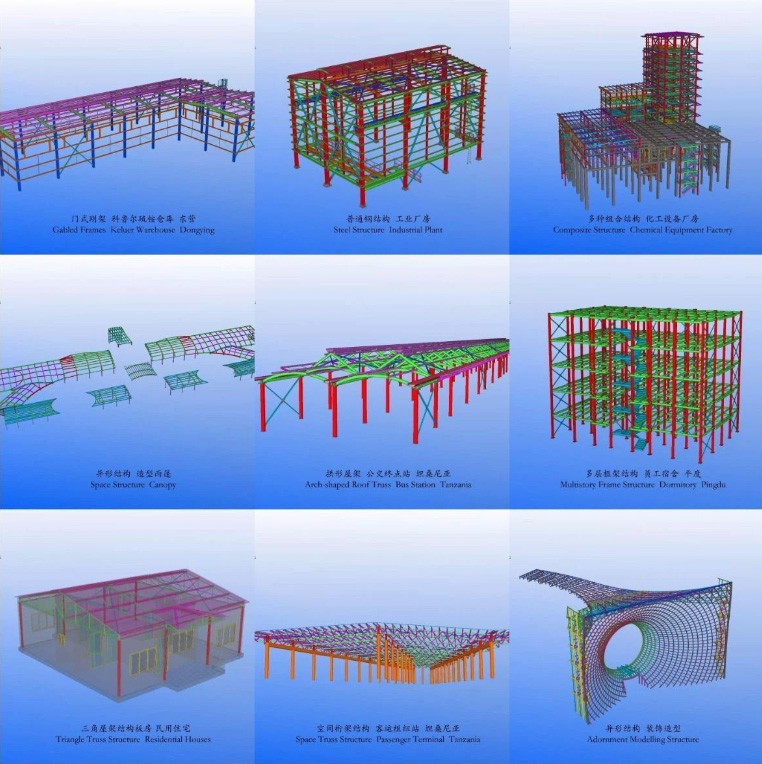

| Drawing Design: | AutoCAD, Sketchup, Tekla, 3D3S |

| Company Info. |

| Qingdao Xinguangzheng Xinyuan Construction Engineering Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

Carbon Steel Pre-Engineered Building For Industrial And Commercial Use

Product Description

What is pre-engineered steel structure building?

Compared with traditional building like concrete building, steel

structure building is a new quick installed building structure. The

structure mainly comprises steel columns, beams, trusses, bracing,

purlins, U channel, angle steel and steel plates, etc... They are

connected together to be frame by welding, bolts and rivets.

Steel frame is typically consisting of vertical columns and

horizontal beams which are bolted or welded together. Steel columns

are vertical structural members that transfer compressive loads. It

can be used to form the skeleton of a building. Steel beams are

horizontal structural members that resist loads applied laterally

to their axis. Structural steel framing is typically designed,

fabricated and erected in accordance with applicable standards to

ensure its safety.

All pre-engineered steel structure buildings’ components are

detailed and manufactured in the factory. To cut, drill and weld

strictly following the manufacturing drawings to ensure that the

structure tolerance is less than 2mm.

Product Parameters

Components of steel structure hangar

● Primary Framing Elements

Columns, beams members are made by H section steels( hot rolled

section steel/ welded section steel), which will be easily bolted

together at site. A factory primer and facing paintings or

galvanization surface treatment are applied to get better

anti-rusting effect of primary framing elements.

● Secondary Framing Elements

Purlin, tie bar are formed as secondary framing, which will fix on

columns and beams by common bolts.

● Bracing

Round steel is supplied with knee bracing and other supporting

parts that need portal framing, which will improve the stability

and durability of the whole structural hangar.

● Cladding

Roof and Wall are covered by color-coated corrugated steel sheet or

steel sandwich panel, hot dipped with zinc and aluminum compound,

that is fixed to the outside of structural building to protect it

against bad weather or to make it look more attractive and last for

generations.

● Windows and Doors

Plastic Steel Window/Aluminum-alloy Window; Sliding Door/Folding

Door.

● Other Options:

Gutter, Downpipe, Transparent sheet, Ventilator and Bridge Crane

will be fitted according to client’s requirements.

| Items | Specification | |

| Main Steel Frame | Column | Q235,Q355B Welded H Section Steel |

| Beam | Q235,Q355B Welded H Section Steel | |

| Secondary Frame | Purlin | Q235B C and Z purlin |

| Knee brace | Q235B Angle Steel | |

| Tie rod | Q235B Circular Steel Pipe | |

| Brace | Q235B Round Bar | |

| Vertical&Horizontal support | Q235B Angle Steel, Round Bar or Steel Pipe | |

| Maintenance System | Roof panel | Roof Panel (EPS/Fiber Glass Wool/Rock Wool/PU Sandwich Panel or Steel Sheet Cover) and Accessories |

| Wall panel | Wall Panel (Sandwich Panel or Corrugated Steel Sheet) | |

| Window System | Aluminum Alloy Window/ PVC Window/ Skylight | |

| Door System | Sliding Sandwich Panel Door/ Rolling Metal Door/ PVC Door | |

| Others | PVC Rainspout, Gutter etc | |

Application

Pre-engineered buildings (PEBs) made of steel are widely used across various industries due to their versatility and cost-effectiveness.

1. Long span structure

With the increase of the span of structure, the weight of the structure in the total load of the larger proportion, reducing the weight can obtain obvious economic benefits.

2. Commercial building

The characteristics of high strength and less pollution are of great significance to commercial buildings.

3. Industrial building

When the span and column distance of the industrial building is large, or with a large tonnage crane, the structure needs to bear large dynamic load, often part or all of the steel structure. In order to shorten the construction period and bring the investment benefit into full play, steel frame has been widely used in general industrial buildings in recent years.

4. Multi-storey building

Multi-storey buildings have become a symbol of modern cities. The characteristics of high strength and light steel structure are of great significance to multi-storey buildings. With high strength, the component section size is small, which can improve the effective use area; Light weight can greatly reduce the load borne by components, foundations and foundations, and reduce the cost of foundation engineering.

5. Light-type structure

It is structure with small load or span. The dead weight is the main load of this kind of structure, which is usually light structure made of cold-formed thin-wall steel or small steel.

Features of Pre-engineered Steel Building

The features of the pre-engineered steel structure building are as

follows:

1. Steel structure is light in weight, high in strength and large

in span;

2. The construction period of steel structure is short and the

investment cost is reduced accordingly;

3. The steel structure is highly fireproofing and

corrosion-proofing;

4. Pre-engineered steel structure building are easy to move and can

be recycled without pollution;

5. Pre-engineered steel structure building material are easy to

transport; We use the steel pallet to load stele structure into the

shipping container;

6. Pre-engineered steel structure building’s foundation will be

reducing than tranditional construction as its light weight.

Project Process

1. The cooperation process begins when a customer sends an inquiry.

2. We then proceed with the design and quotation phase, where our

team works closely with the customer to create a tailored solution.

3. Once the project is approved, it moves to our factory for

manufacturing and fabrication.

4. After completion, the finished product is shipped to the

customer's country for installation. We will provide customers with

construction drawings and installation videos, and provide online

guidance. If customers have specific needs, we can also send

construction personnel to the customer's country for offline

installation guidance.

5. Finally, after the installation, the project is complete

successfully.

Our Service

Services of Xinguangzheng Group

Our company can design, fabricate, load and erect the

pre-engineered steel structure building according to clients’ need.

1. Make suitable design plan and detail construction drawings of

steel structure building according to the land layout area and

usage of building by Tekla, PKPM, 3D3S.

2. Pre-engineered steel structure building consultation service.

3. Budget offers of building for contractor.

4. Transportation & delivery as your need.

5. Fabrication,shot blasting & painting as different request.

6. Erection & installation of pre-engineered steel structure

building. Our technician and skilled workers can be on site to

guide or install the building as need.

Customers Visiting

Welcome to our company to visit our factories, there we will show you our professionalism. We have a total of six plants, several production lines running at the same time, we believe that enough to meet your needs. Welcome you again.

FAQ

1. What kind of company you are?

We are steel structure building Manufacturer located in Qingdao China. We are manufacture factory. And you are welcomed to visit us at any time. The quality control flow and sales team will show you our professionalism.

2. Is your price competitive compared to other companies?

Our business objectives are to give the best price with same quality and best quality with the same price. We will do everything to reduce your cost and guarantee you get the best product that you paid for.

3. Do you offer designing service for us?

Yes, we could design full solution drawings as your requirements. By using AutoCAD, PKPM, MTS, 3D3S, Tarch, Tekla Structures (Xsteel) and etc.

4. How to buy my idea products?

You can provide us your drawing, and we can produce as your

drawings.

Or we can design as your requirements if you don’t have a clear

plan. We will provide our plans according to the local climatic

condition.

5. Can you send engineers to install my structures?

We can provide you with detailed installation drawings and videos for free, and we can also send engineers as installation directors upon request.

|