| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Metal Frame Parts |

|---|---|

| Brand Name: | Xiange |

| Model Number: | MFA-XG-038 |

| Certification: | ISO9001:2015 |

| Place of Origin: | China |

| MOQ: | 1 pcs |

| Price: | USD $0.1-$1.99 |

| Payment Terms: | T/T, Western Union, MoneyGram |

| Supply Ability: | 50000 pcs per week |

| Delivery Time: | Samples 7-10 days, Mass production 20-25 days |

| Packaging Details: | Carton, As Customers'packaging requirements |

| Supply type: | OEM Service |

| Material Capabilities: | Stainless Steel, Brass, Aluminum, Steel |

| Process: | Bending, Laser Cutting, Welding, Stamping |

| Application: | Auto,motorcycle,industry,ariculture,furniture,elevator,etc |

| Packing Details: | Carton, Wooden Case, Plastic Cargo |

| Color: | Black, Silver, Customized Color |

| Company Info. |

| Shenzhen Xianheng Technology Co.,Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

Precision Sheet Metal Fabrication Stamping Parts Bending Stainless Steel Bracket Frame

Description Of Customized High Quality Metal Frame Parts Precision Sheet Metal Fabrication

Customized High Quality Metal Frame Parts Precision Sheet Metal Fabrication offers specialized services in the design and manufacturing of metal frame parts with a focus on precision, durability, and customization. These services are essential for various industries that require robust and accurate metal components.

Custom Metal Frame Parts:

Precision Engineering: Utilizing advanced CAD/CAM software and CNC

machinery to design and fabricate metal frame parts with high

precision and exact specifications.

Complex Designs: Capable of producing intricate frame parts with

various shapes and structures to meet specific application

requirements.

Sheet Metal Fabrication:

Cutting: Employing state-of-the-art laser cutting, water jet

cutting, and plasma cutting technologies to achieve precise cuts

with minimal waste and high efficiency.

Bending: Using CNC press brakes and other bending equipment to form

metal sheets into complex angles and shapes with high accuracy.

Forming: Implementing various forming techniques, such as rolling,

folding, and stamping, to create detailed and complex metal parts.

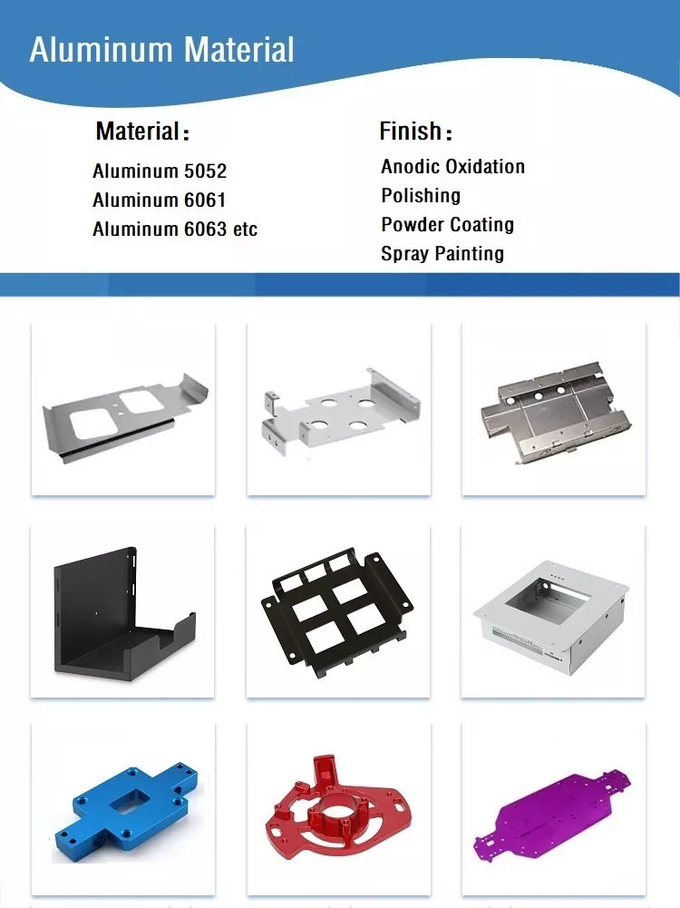

Material Of Customized High Quality Metal Frame Parts Precision Sheet Metal Fabrication

Material Available

| Stainless Steel | SS201,3031, 304, 316, 17-4PH, SS303, SSs304, SS316 etc. |

| Steel | 4140, 4340, middle steel, Carbon steel, Q235, 20#, 45# etc. |

| Brass | C36000(C26800),C37700(HPb59), C38500(HPb58),C27200(CuZn37), C28000(CuZn40) |

| Bronze | C51000, C52100, C54400, etc. |

| Aluminum | 6082, 6061, A380, Al6061, Al6063, AL7075, AL5052 etc. |

| Iron | 1213, 12L14, 1215 etc. |

Plastic | ABS, PC, POM, Delrin, Nylon, Teflon, PP etc. |

Surface finish

| Aluminum parts | Stainless Steel parts | Steel | Plastic |

| Natural anodize | Polishing | Blackened | Plating gold (ABS) |

| Hard anodize | Plating | Zinc plating | Laser engraving |

Powder coating Sandblasting | Sandblasting | Nickel plating | Painting |

| Plating | Laser engraving | Chrome plating | Brushing (Acylic) |

| Brushing | Carburized | ||

| Polishing | Hot treatment | ||

| Laser engraving |

Application Of Customized High Quality Metal Frame Parts Precision Sheet Metal Fabrication

1. Construction: Metal angle brackets are extensively used in the construction industry for connecting beams, joists, and rafters. They provide critical support and reinforcement to building structures, ensuring stability and load distribution.

2. Shelving: Angle brackets are widely used as shelf supports for wall-mounted shelves in homes, offices, retail stores, and warehouses. They help create sturdy and reliable shelving systems.

3. Furniture Assembly: Metal angle brackets are essential in furniture assembly, helping to connect components and reinforcing joints in tables, chairs, cabinets, and bed frames.

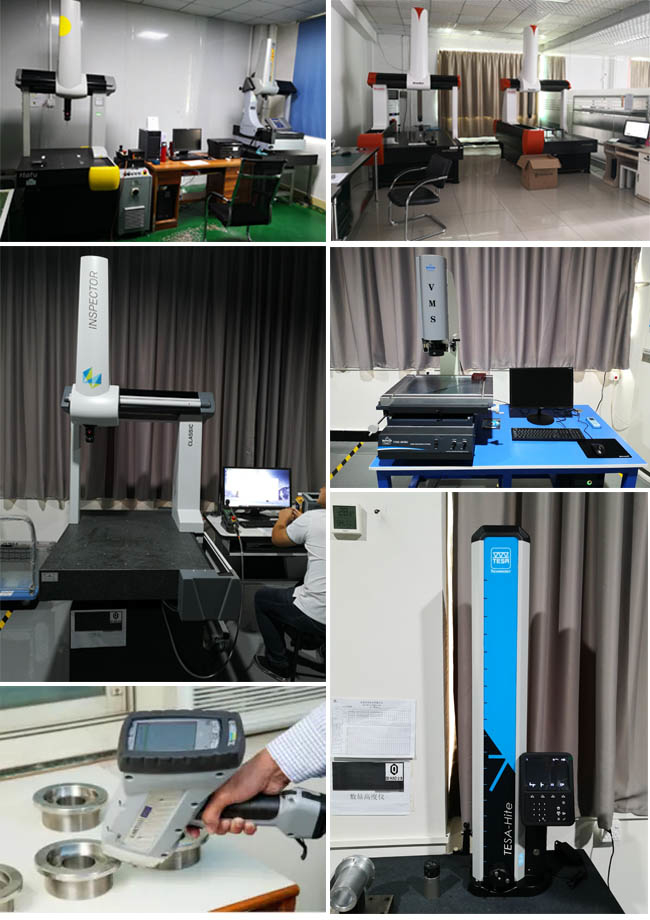

Quality Control

1. Checking the raw material after they reach our factory------- Incoming quality control ( IQC)

2. Checking the details before the production line operated

3. Have full inspection and routing inspection during mass

production---In process quality control(IPQC)

4. Checking the goods after they are finished---- Final quality

control(FQC)

5. Checking the goods after they are finished-----Outgoing quality

control(OQC)

Advantages

1. Quality control: the defective products rate is 0.1%. Imported material 100%.

2. Reasonable price. Precision made. Experience & reasonable QC that you can reply on.

3. Each part would be given 100% test and tryout before shipment.

4. Adequate supply capacity. Punctual delivery time.

FAQ

Q1: Where can I get product & price information?

A1:Send us inquiry e-mail, we will contact you as we receive your

mail.

Q2: How long can I get the sample?

A2:Depends on your specific items, within 3-7 days is required

generally.

Q3: What kinds of information you need for quote?

A3:Kindly please provide the product drawing in PDF, and will be

better you can provide in STEP or IGS.

Q4: What are the payment terms?

A4: We accept 50% as payment deposit, when the goods is done, we

take photos for your check and you then pay the balance.

Q5: Are you a trading company or factory?

A5:We are direct factory with 10 experienced engineers and more

than 650 employees as well approximate 2,000 square ft. workshop

area.

Q6: What shall we do if we do not have drawings?

A6:Please send your sample to our factory, then we can copy or

provide you better solutions. Please send us pictures or drafts

with dimensions (Length, Hight, Width), CAD or 3D file will be made

for you if placed order.

|