| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Metal Combine Screw |

|---|---|

| Finish: | ZINC, Plain, Black |

| Material: | Stainless steel, Steel, Brass, Stainless steel,Carbon steel,Nickel,ronze,C1022a,Plastic,brass |

| Place of Origin: | Guangdong, China |

| Brand Name: | Juhao |

| Model Number: | Customized Bolt |

| Standard: | ISO,DIN,GB,ANSI |

| Surface treatment: | Black oxide,Zinc-aluminum coated,Zinc plated,Chrome,Hot dip galvanized |

| Grade: | 4.8/ 8.8/ 10.9/ 12.9 /grade5/grade8 Ect |

| Size: | M3-M56 |

| Certificate: | SGS ROHS ISOISO9001:2015 |

| Package: | Customer'require |

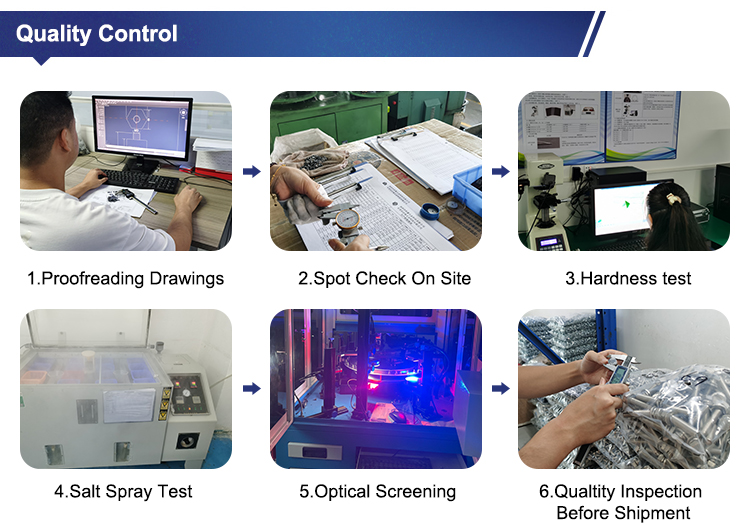

| Quality Control: | 100% Inspection Berore Shipment |

| Advantage: | OEM/ODM One-stop Customized Service |

| Packaging Details: | 25kg Per Carton and 36 Cartons Per Pallet |

| Port: | SHENZHEN GUANGZHOU PORT |

| Supply Ability: | 1000000 Piece/Pieces per Month |

| MOQ: | 1000 pieces |

| Price: | $0.10/pieces 1000-9999 pieces |

| Company Info. |

| Shenzhen Juhao Hardware Technology Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

Finish | Blue zinc,white zinc,Black oxide,Chrome plated,Zinc-aluminum

coated,Zinc-flake coated,Blue anodized,Blue dyed,Cadmium plated,Chrome,Hot dip galvanized |

Material | Stainless steel,Carbon steel,Nickel,Copper,C1022a,Plastic,brass |

Model Number | Customized bolts |

Standard | ISO,DIN,GB,ANSI |

Surface treatment | White Zinc .Yellow Zinc. Black Zinc.Blue zinc.HDG |

Grade | 4.8/ 8.8/ 10.9/ 12.9 Ect grade 5 / 8 |

Size | M3-M56 |

Certificate | SGS ROHS ISOISO9001:2015 |

Package | Customer'require |

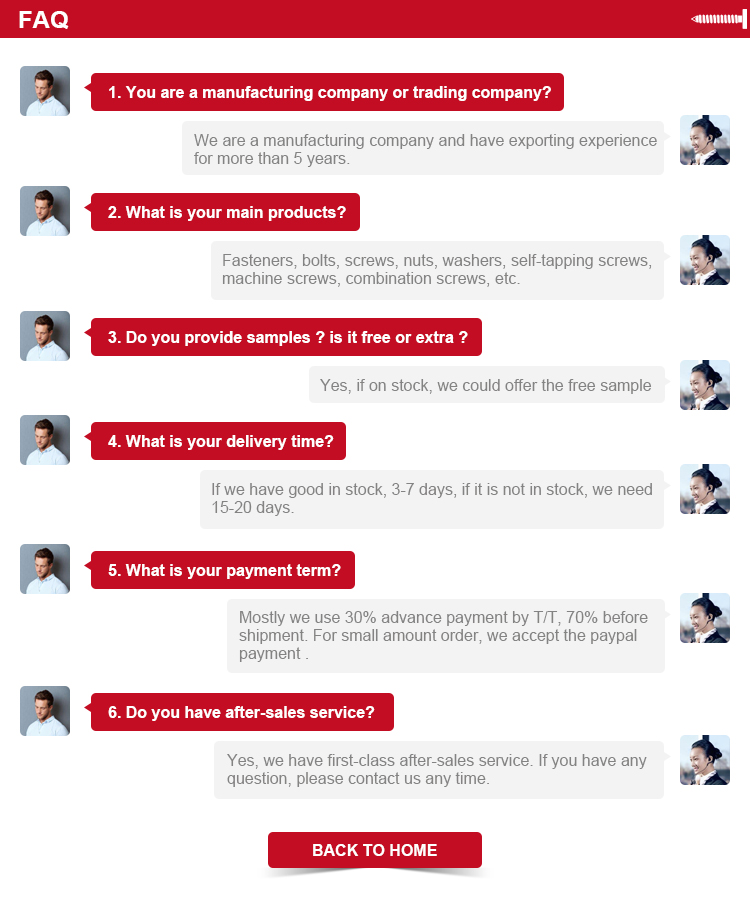

Question 1 | 1.Why is stainless steel magnetic? |

304 stainless steel belongs to austenitic stainless steel,

austenite in the cold working process in part or a small amount of transformation into martensite, martensite is magnetic, so 304 stainless steel is non-magnetic or slightly magnetic. | |

Question 2 | 2. How to identify authentic 304 stainless steel products? |

①Support 304 stainless steel special test potion detection, if not

discoloured for the authentic 304 stainless steel | |

② support chemical composition analysis, spectral analysis | |

③ support salt spray test, simulate the actual use of the

environment | |

Question 3 | 3. What are the most commonly used stainless steel? |

① 201 stainless steel, suitable for use in dry environments, easy

to rust in water | |

② 304 stainless steel, outdoor or wet environment, corrosion

resistance and acid resistance | |

③ 316 stainless steel, plus molybdenum, more corrosion resistance

and pore erosion resistance, especially for seawater and chemical media |

|