| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | GEA Heat Exchanger Plate |

|---|---|

| Brand Name: | GEA |

| Model Number: | VT04、VT10、VT20、VT40、VT80、VT405、VT2508、N40、FA184、NT50、NT100T、NT100M NT100X、NT150S、NT150L、NT250S、NT250M、NT250L、NT350S、 NT350M、NT50 |

| Certification: | ISO SGS |

| Place of Origin: | China |

| MOQ: | 20PCS |

| Price: | 50 - 500pieces $20-$30 |

| Payment Terms: | T/T, L/C, Western Union, |

| Supply Ability: | 50000pcs per month |

| Delivery Time: | 15 days |

| Packaging Details: | Polywood Box |

| Connection Size: | DN50 |

| Connection Type: | Flanged |

| Heat Transfer Area: | 0.5m² |

| Material: | Stainless Steel |

| Max. Working Pressure: | 10 bar |

| Max. Working Temperature: | 150°C |

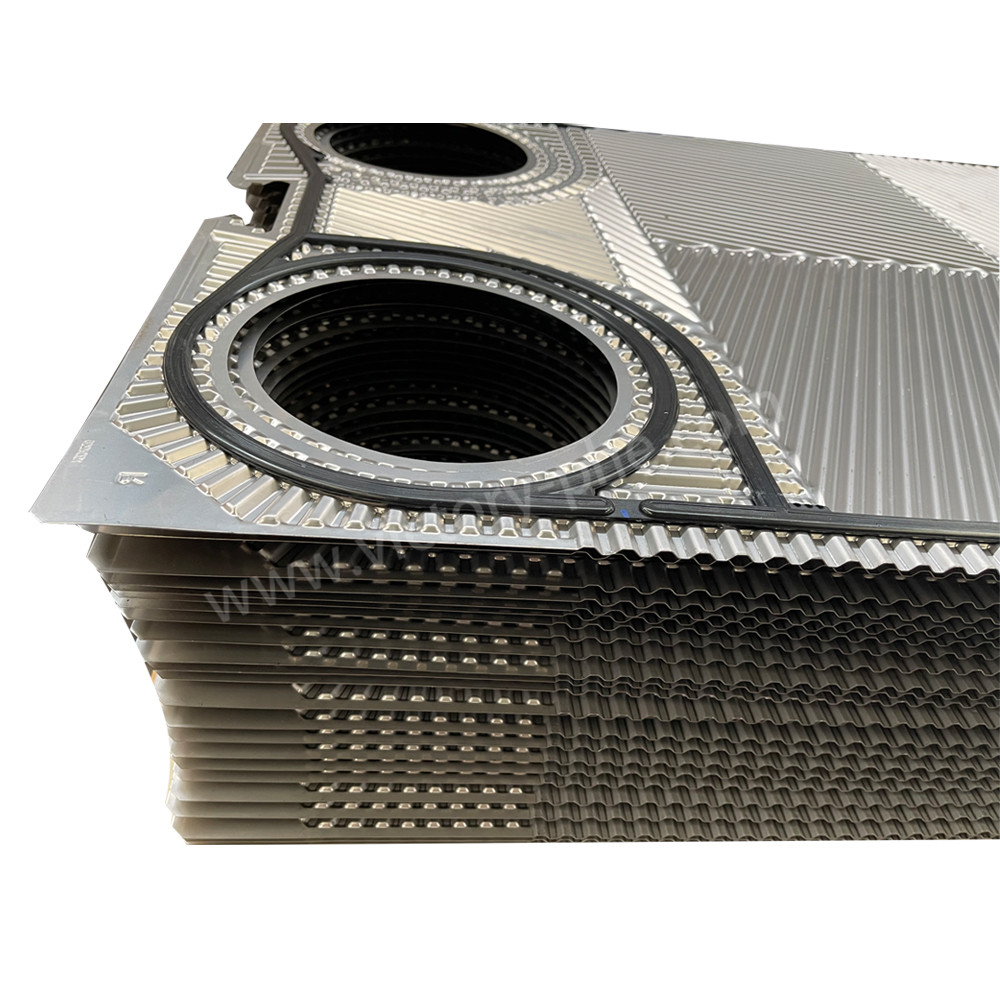

| Plate Corrugation Depth: | 3mm |

| Plate Material: | EPDM |

| Plate Pattern: | Herringbone |

| Plate Pitch: | 5mm |

| Plate Size: | 600mm x 600mm |

| Plate Thickness: | 0.5mm |

| Plate Type: | Gasketed |

Product Description

GEA Heat Exchanger Plates

GEA VT04/VT10/VT20/VT40/VT80/VT405/VT2508 Relplacement Plate Heat Exchanger Plates

Plate heat exchangers (PHE) are commonly chosen for food and beverage processing due to several reasons:

Efficient Heat Transfer: Plate heat exchangers offer high heat transfer efficiency, allowing for rapid heating or cooling of food products, which is crucial in food processing.

Hygienic Design: PHEs have a compact and sanitary design with smooth surfaces, making them easy to clean and sanitize, ensuring food safety and meeting strict hygiene standards.

Flexibility: Plate heat exchangers can handle a wide range of food products with varying viscosities, temperatures, and particulate sizes, making them versatile for different processing needs.

Compact Size: PHEs have a compact footprint compared to other heat exchanger types, saving space in food processing plants where space efficiency is important.

Temperature Control: Plate heat exchangers provide precise temperature control, allowing for accurate processing and preservation of food products without compromising quality.

Energy Efficiency: PHEs help optimize energy usage in food processing by efficiently transferring heat, reducing energy costs and environmental impact.

Overall, the efficient heat transfer, hygienic

| Brand | Model |

| GEA | VT04,VT10,VT20,VT40,VT80,VT405,VT2508,N40,FA184,NT50,NT100T,NT100M NT100X,NT150S,NT150L,NT250S,NT250M,NT250L,NT350S, NT350M,NT500 |

| Material | Specification |

| Stainless Steel | SUS304 316 316L 310S 904 |

| Titanium and titanium-palladium alloy | TAi TAi-Pd |

| Hastelloy | C276 D205 B2G |

| Nickel | Ni200 Ni201 |

| Molybdenum | 254 |

Applacations

| Plate material | Suitable for fluids |

| Stainless steel (SUS304.316, etc.) | Purified water, river water, edible oil, mineral oil |

| Titanium and titanium palladium (Ti, Ti-Pd) | Sea water, salt water, salt compounds |

| 20Cr,18Ni,6Mo(254SMO) | Dilute sulfuric acid, dilute salt aqueous solution, inorganic aqueous solution |

| Nickel (Ni) | High temperature, high concentration caustic soda |

| HASTELLOY alloy (C276, D205, B2G) | Concentrated sulfuric acid, hydrochloric acid, phosphoric acid |

Heat exchanger plate Choose:

Production Process:

The production of stainless steel plates for plate heat exchangers involves several precise steps to ensure high-quality performance and longevity.

Q&A

1. Q: Are you a manufacturer or trading company?

A: We are a professional manufacturer of plate heat exchangers, plates, gaskets, plate mould with 18 years' experience.

|