| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | ADSS Cable |

|---|---|

| Brand Name: | Fiberplan |

| Model Number: | ADSS |

| Certification: | ISO 9001; TÜV certificate |

| Place of Origin: | China |

| MOQ: | 1Km |

| Price: | Negotiation |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability: | 5000Km per month |

| Delivery Time: | 5-8 work days |

| Packaging Details: | Wooden Drum |

| Application: | Telecommunication,Aerial,Telecom,Network |

| Fiber type: | G652B, G652D, G657A1, G657A2, 62.5/125, 50/125 |

| Jacket material: | PE,LSZH,PVC,TPU,LSZH OR PVC |

| Name: | ADSS Optical Fiber Cable |

| Installation: | self- supporting Aerial |

| Fiber Count: | 12-144 |

| Tensile Strength: | 10-20kN |

| Installation Method: | Self-supporting |

| Packing: | 2-4km/wooden Drum |

| Span Length: | 100-500m |

| Structure: | stranded looose tube |

| Temperature Rating: | -40°C ~ +70°C |

| Term: | EXW/FOB/CIF |

| Company Info. |

| Dongguan Guanhong Optical Cable Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

Double Sheath Aramid Yarn Reinforcing ADSS Self Supporting Cable

Description

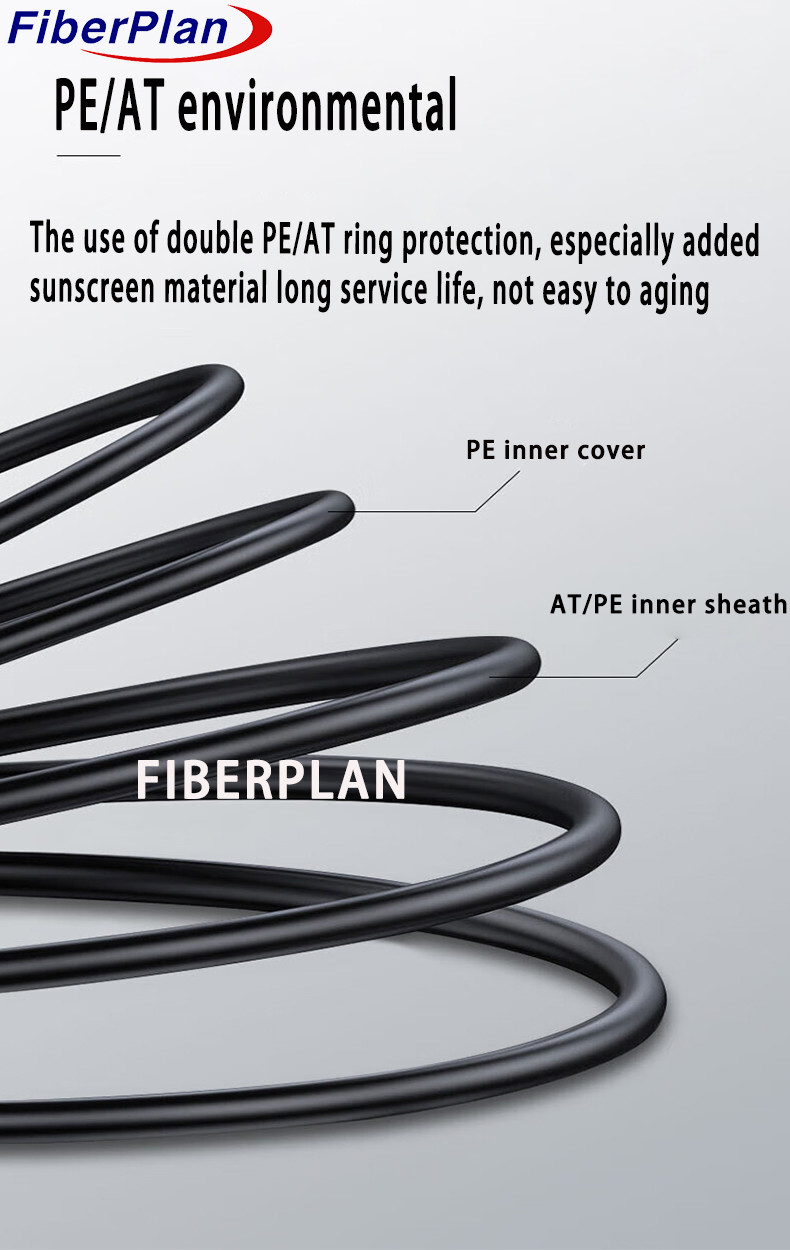

The ADSS cable employs a loose tube stranded design, housing fibers within high modulus plastic tubes

filled with a water-resistant compound. These tubes, along with fillers, are wrapped around a non-metallic

central strength member (FRP) to form a tight circular cable core, which is then filled with compound for

added protection. A thin PE inner sheath is applied over the core, followed by a layer of aramid yarns for

strength. Finally, the cable is finished with either a PE or AT outer sheath for additional protection and in-

sulation.

Application

1 ADSS cable design adapts to overhead power line specifics.

2 PE outer sheath for lines below 110kV; AT sheath for 110kV+ lines.

3 Tailored aramid and stranding suit diverse span requirements.

Characteristics

1 Non-disruptive installation without power shutdowns.

2 Light and small size to alleviate ice, wind, tower, and backprop loads.

3 30-year design life expectancy.

4 Excellent tensile strength and temperature performance.

Nominal design parameters

| NO. of fibers | 6 | 12 | 24 | 48 | 72 | 96 | 144 |

| No. of tubes | 1 | 2 | 4 | 4 | 6 | 8 | 12 |

| Filler rod | 5 | 4 | 2 | 2 | 0 | 0 | 0 |

| fibers per tube | 6 | 6 | 6 | 12 | 12 | 12 | 12 |

| Nom. tube diameter (±0.2mm) | 2 | 2 | 2.0 | 2.0 | 2.0 | 2.0 | 2.0 |

| Nom. diameter (±0.5mm) | 12.3 | 12.3 | 12.3 | 12.3 | 12.3 | 13.0 | 15.0 |

| Loose tube | Material | PBT | Color | Standard spectrum | |||

| Filler rod | Material | PP | Color | Black | |||

| Maximum tensile strength | 4000N | ||||||

| Maximum crush load | 3000N/100mm | ||||||

| Minimun bending radius | 10D | ||||||

| Span length | 100m - 500m | ||||||

| Out sheath material | PE | ||||||

| Temperature range | -20℃ ~ 70℃ | ||||||

Fiber characteristics

| Fiber type | Unit | SM G652D | MM 50/125 | MM 62.5/125 | |||

| Condition | mm | 1310/1550 | 850/1300 | 850/1300 | |||

| Attenuation | dB/km | ≤0.36/0.24 | ≤3.0/1.5 | ≤3.0/1.5 | |||

| Cladding diameter | um | 125±0.4 | 125±0.4 | 125±0.4 | |||

| Cladding non-circularity | % | ≤1.0 | ≤1.0 | ≤1.0 | |||

| Coating diameter | um | 242±5 | 242±5 | 242±5 | |||

|