| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Steel Structure Workshop |

|---|---|

| Brand Name: | GST |

| Model Number: | Steel Frame Structure |

| Certification: | ISO 9001, CE |

| Place of Origin: | China |

| MOQ: | 1000 square meters |

| Price: | USD 30-60 per square meter |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 2000 tons per month |

| Delivery Time: | 30~35 days |

| Packaging Details: | Steel components are packaged with steel pallets at the factory with the coding number, which is convenient for customers to unload |

| Product name: | Steel Structure Workshop |

| Standard: | GB |

| Type: | Light steel |

| Drawing Design: | SAP2000/AutoCAD /PKPM /3D3S/TEKLA |

| Tolerance: | ±1% |

| Purlin: | Hot Dipped Galvanized C Z Purlin |

| Application: | Steel Workshop/Warehouse |

| Surface treatment: | Hot Dip Galvanized and Painted |

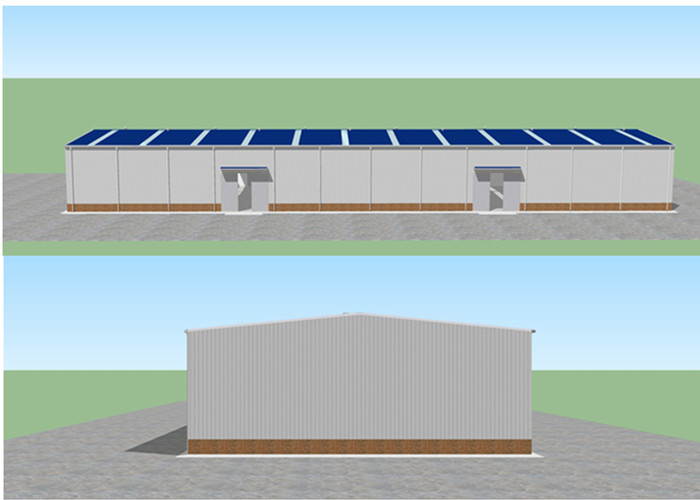

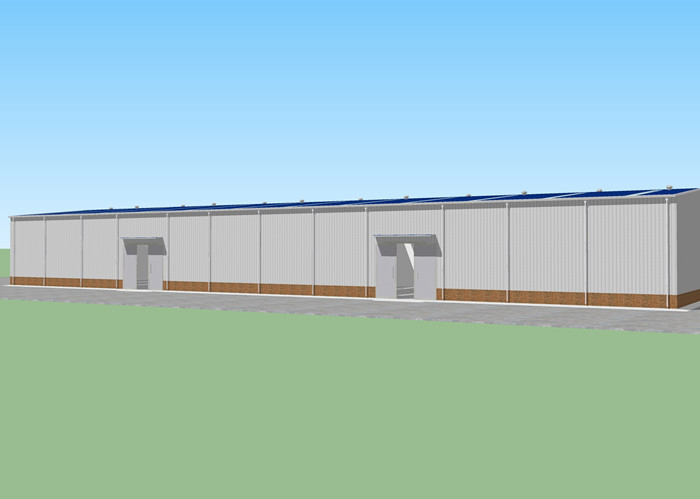

Industrial Steel Structure Workshop Construction Prefab

MultiFunctional

Product Description:

1. The strength of Steel Frame Buildings is higher than traditional

brick and concrete structures. Steel structure buildings are also

much stronger than a traditional wood structures. So, it can build

more structures higher than traditional building materials.

2. Steel Frame Buildings perform better earthquake resistance than

traditional building materials such as brick concrete structures

and wood structures. Because it has better flexibility. So, if want

to build a high-level building, using a steel structure build is a

good idea because it can resist earthquakes.

3. Steel metal building are easily customizable in their appearance

and can be designed to fit a certain local or a specific company

brand. From eaves to massive garage doors to skylights, we can make

sure that your building has the look pictured in your head.

Characteristics of steel structure workshop:

1. Easy to assemble

The steel components arriving at the construction site are all

prefabricated. During the construction process, the installation

work needs to layout each structure and erect it according to the

installation drawing.

The installation sequence of the steel workshop building is:

First, install the steel columns and column cross-bracing and

install roof beams and roof horizontal bracing. Finally, installs

the purlin and enclosure structure.

2. Reasonable cost:

The steel structure workshop building is light in weight, reducing

the basic cost, and the construction speed is fast. It can be

completed and put into production as soon as possible. The overall

economic benefits are much better than that of the concrete

structure

3. Simple construction, short construction period.

The production and installation of steel structure usually involve

processing all required components in the factory and then

transporting to the construction site to assemble. So the

construction period is greatly shortened. A 4000 square meter

building can be basically installed in only 40 days.

4. Energy-saving and environmentally friendly

The corrugated color steel sheet and sandwich panels used in the

prefab steel structure workshop are all energy-saving materials.

The steel structure also adopts dry construction during the

construction process to avoid dust and environmental pollution

caused by concrete construction.

Product specifications

| Product name | Industrial Steel Structure Workshop Construction Prefab MultiFunctional |

| Column and beam | H section steel |

| Purlin | C/Z section steel |

| Wall & roof material | 50/75/100/150mm EPS/PU/rockwool/fiberglass sandwich panel |

| Connect | Welding connection or Bolt connect |

| Window | PVC or aluminum alloy |

| Door | Sliding door, Roll up door |

| Certification | ISO9001/CE |

Company profile:

Qingdao Gusite Construction Technology Co, Ltd. was established in

2014. lt is a high-tech, diversified and export-oriented

large-scale international private enterprise integrating R&D,

design, production, installation and construction at home and

abroad, and technical services.

Gusite has the qualification certificate of China's overseas

contracted project management issued by the Ministry of Commerce of

China, CE certification [EN1090 certificatel), ISO9001 certificate,

etc, and has carried out long-term cooperation with countries along

the "Belt and Road". The current products and construction services

have been exported to more than 50 countries around the world,

including Asia, Africa, North and South America. ln addition.

branches have been established in Mozambigue and Angola, which can

undertake steel structure installation projects in Africa

Production capacity:

The company can produce more than 30 kinds of series products with

different structures and specifications. It has complete processing

and manufacturing equipment and strong installation capabilities.

It can supply a full set of materials required for steel structure

construction projects, and provide all installation services and

technical consultation.

The company has 2 composite board production lines with an annual

output of more than 1 millionmeters; 5 color steel plate production

lines with an annual output of 2 million meters; 2 H-beam CNC

production lines with an annual output of 20000 tons: One C-beam

production line with an annual output of 2500 tons; One Z-Beam

steel production line with an annual output of 2,000 tons.

in addition to various section-steel products, it can also

manufacture color steel sheets, compositepanels, lighting panels,

ventilators, etc.

Qualification certificates:

Services:

We can provide you with a complete service from quote, design,

manufacture, etc, according to your requirements & drawing. The

manufacture procedure including drilling, rust-removing, shot

blasting, nondestructive detecting, painting and so on.

When designing and building any structure, there are many factors

to consider such as safety, strength, cost and maintenance, etc.

The materials must also be sustainable and environmental, thus to

make a contribution towards the sustainability of the project

itself.

chooseing the correct material for the task is vital, and this

choice is now influenced by economic and environmental pressures

that were not important several years ago. Save the tree and our

earth, please choose light gauge steel framed house. Our technical

and R&D support are ready to help you chose the correct grade

of steel for each application, which can result in the most cost

effective solutions for today’s architecture, building and

construction requirements.

Packing and loading:

Our technical team will do the economical packing plan for clients,

calculate the quantity of steel structure materials accurately and

use the min. quantity of containers, to save the shipping freight

for clients.

When packing we use the pallets according to container's size, to

improve the loading unloading efficency.

Quote information

Could you tell me your requirement for your steel structure

project?

Basic design requirements and design Load,

1. Project site location:

2. Overall dimension (length*width*eave height in meters):

3. Mezzanine of not? How many kgs of load per square meter on

mezzanine?

4. Single-layer steel sheet wall or sandwich panel wall:

5. Snow load if applicable:

6. Wind speed/load:

7. Interior column allowed or not:

8. Overhead crane needed or not, capacity:

9. Any other particular requirements

FAQ

Q1: You are manufacture factory or trading company?

A: We are direct manufacture for steel structure buildings. we have

rich experiance of steel structure designing,manufacturing,

processing and installation.

Q2: Is your price competitive with other companies?

A: Our business goal is to give you the best price with same

quality and best quality with the same price. We will try our best

to reduce your cost.

Q3: Do you offer service for installation?

A: We will give detailed installation drawings and video for free.

And if you need, we could send engineers as installation director

even a team.

Q4: Do you accept container loading inspection?

A: You are welcomed to send an inspector, not only for the

container loading, but any time during the production time.

Q5: Do you offer designing service for us?

A: Yes, we have experienced design team,and we can design full

solution drawings as your requirements.

Q6: What is the delivery time?

A: Delivery time depends on order quantities. Generally, the

delivery time will be 30 days after receiving deposit.

Q7: How can you get a quotation for your projects?

A: You can chat with us anytime or you can just fill out our

questionnaire and send back to us. We will give you the best

quotation asap.

|