| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Side Sealing Packing Machine |

|---|---|

| Brand Name: | Sayok |

| Model Number: | SN-280D6 |

| Certification: | CE |

| Place of Origin: | China |

| MOQ: | 1 set |

| Price: | EXW US$13700-15388/set |

| Payment Terms: | T/T |

| Supply Ability: | 50 set /month |

| Delivery Time: | 20-30 working days |

| Packaging Details: | Exported wooden case |

| Feature: | 6 lanes for high productivity |

| Folding way: | half fold 2 layer or single layer no fold |

| Packing film: | 0.08 mm composite film |

| Packing: | 4 side seal packing machine |

| Operation Mode: | Touch Screen |

| Driven Type: | Mechanical |

| After-sales service: | Video technical support |

| After Warranty Service: | Video technical support |

| Company Info. |

| Foshan Sayok Intelligent Machinery Co., Ltd., |

| Verified Supplier |

| View Contact Details |

| Product List |

High Productivity 6 Lanes Four Side Seal Packing Machine For Alcohol Pre Pads

Facture:

1. Modular Design for Scalability: A modular design allows for scalability, enabling businesses to expand production capabilities by adding modules or units to the existing system as demand increases.

2. Real-time Monitoring and Reporting: Advanced machines may include real-time monitoring capabilities and reporting tools. This allows operators to track production metrics, identify potential issues promptly, and optimize the manufacturing process for efficiency.

3. Automatic Fault Detection and Correction: To minimize downtime and improve efficiency, some machines are equipped with automatic fault detection and correction systems. These systems can identify issues during production and take corrective actions without manual intervention.

4. Environmentally Friendly Features: In alignment with sustainability goals, certain machines incorporate environmentally friendly features such as energy-efficient components and recyclable packaging materials, contributing to a more sustainable production process.

5. Remote Accessibility: With the integration of smart technologies, some machines offer remote accessibility. Operators can monitor and control the machine from a distance, facilitating efficient management and troubleshooting.

6. Multi-Language Support: To cater to a global market, many Alcohol Swab Packaging Machines support multiple languages in their user interfaces, ensuring ease of operation for operators from different linguistic backgrounds.

Specifications:

| Model | SN-280D6 |

| Packing Speed | 700~800/min (bag/min) |

| Expended size | 30x60 or 60x60mm |

| Folded size | 30*30mm |

| Folding way | Folded once, 2 layer or no folded single layer |

| Packing Size | L*W 50*50mm, lenth can be customized |

| Power Supply | 220/380V 50/60Hz |

| Power | 5KW |

| Machine size | (L*W*H)2500×1200×1500mm |

| Raw materials | Coiled, 30-60g/㎡ spunlace non-woven fabric, diameter ≤600mm, width 60mm 30/70 R/T or 50/50 R/T |

| Machine Weght | Approx 500kg |

| Film width | 600mm(mm) |

| Packing film | 73-110g/㎡ paper-aluminum film composite wrapping paper, Φ≤350 mm, width 600 mm, inner diameter of paper core 76.2 |

| Place of Origin | GUANGDONG,CHINA |

| Applicable industries | Commonly used in the medical, healthcare, and cosmetic industries |

Machine Details:

1. Packaging machine appearance making and packing 2 in 1 machine. reasonable design and stainless steel appearance. Durable and long life in use. |  |

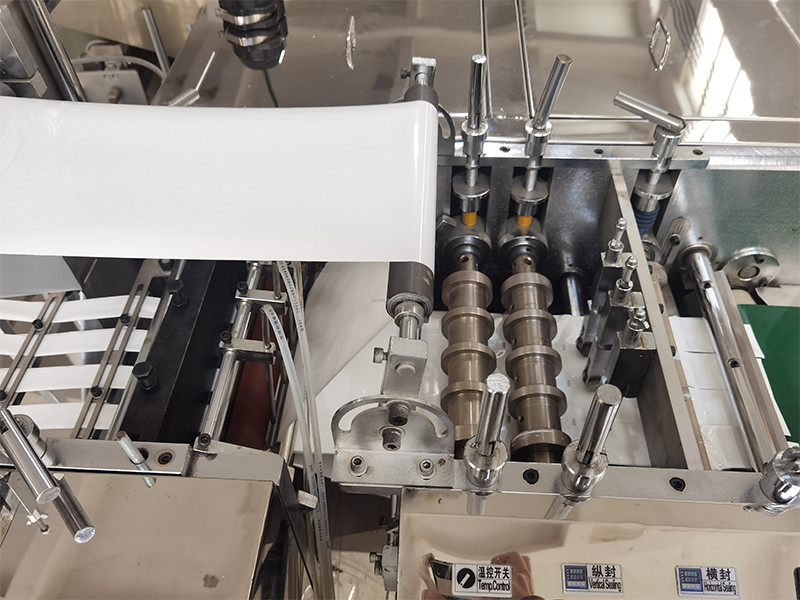

2. Fully automated sealing and cutting Snug structure and reasonable design, small footprint with large functions. 6 lanes, can be with or without slitting, more compatible for the non-woven raw material. Easier to get the raw materials with an more economic price. |  |

3. Support two different materials packaging film Can be single roll (top and bottom layer of the same material) can be double roll (top and bottom layer of different materials), convenient for different product packaging options. |  |

4.Fullyautmatic |  |

5. Liquidaddition |  |

6.Good sealing |  |

| 6.Support for custom We can customize designs according to customers' needs to meet

diverse needs. Our technical department can also help you to

analyze, design and test your new products. |  |

|