| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Waste Oil Distillation Plant |

|---|---|

| Brand Name: | Huayin |

| Model Number: | HY-5Ton |

| Certification: | CE ISO |

| Place of Origin: | Xinxiang , henan , China |

| MOQ: | 1 |

| Price: | USD35000-75000 per set |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 250 sets per year |

| Delivery Time: | 15 working days |

| Packaging Details: | plastic flims for pyrolysis reactor , wooden boxes for small parts |

| Input raw material: | waste engine oil /pyrolysis oil /motor oil |

| Output product: | diesel , slag |

| Structure form: | horizontal |

| cooling method: | circle water cooling |

| Advantage: | energy saving |

| Function: | plastic pyrolysis oil refinery plant waste tire pyrolysis oil to diesel fuel |

Huayin Plastic Pyrolysis Oil Refinery Plant Waste Tire Pyrolysis Oil To Diesel Fuel

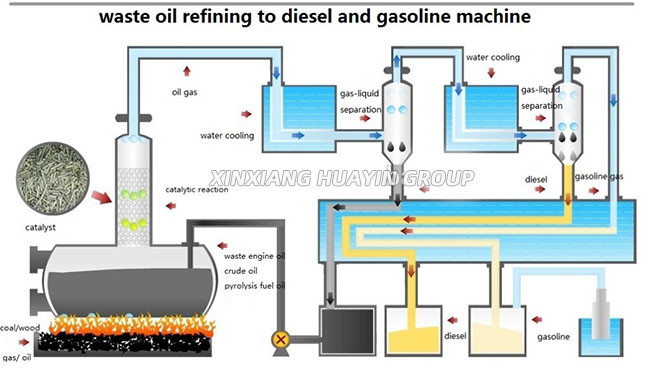

Distillation is the chemical engineering processes and other facilities used in oil refineries to distills the incoming crude oil, pyrolysis oil and waste oil into useful products such as diesel oil and fuel oils, gasoline or petrol, jet fuel, etc.

Working process of the waste engine oil /pyrolysis oil distillation plant

1. Prepare two waste engine oil storage oil tanks around 50m³, use the oil-water separator to remove the waste engine oil water content to 1% max, then use the oil pump to pump waste engine oil into the distillation reactor, then heat the reactor by wood, gas, oil or coal to let the oil begin to refine. The distillation column shall separate the light oil and diesel oil purely.

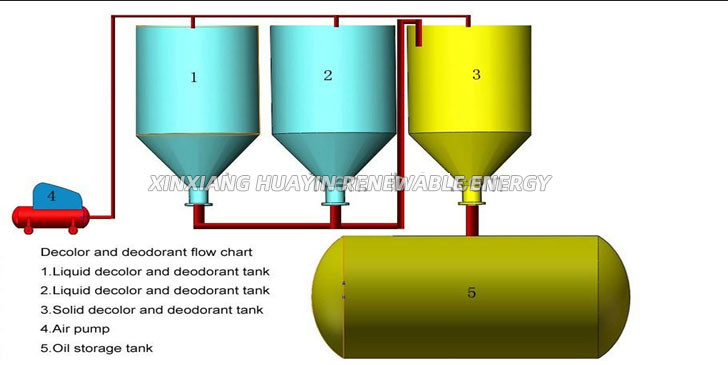

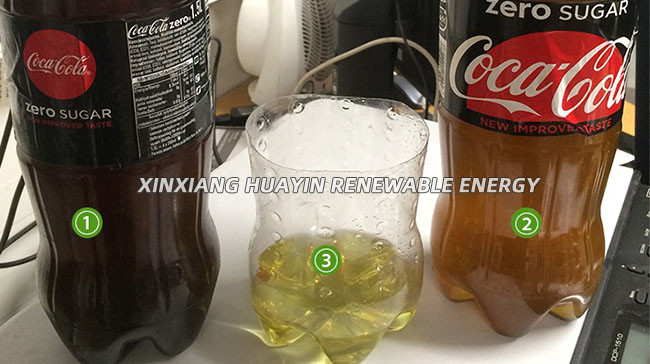

2. After the distillation process, then put the final product into the Color and smell removal system for further processing, this can improve the oil quality and make the color is lighter, and the smell is less.

Main features

Safety: Alarm, auto pressure releasing device, anti backfire device, vacuum pump to ensure the machine working smoothly.

Oil-water separator: Its water sealing design ensures that oil and gas are separated and combustible gas can not return to the reactor.

Energy-saving:

The inner reactor body and outside insulation cover have good airtightness, avoiding heating loss and saving fuel.

The combustible gas that cannot be further cooled down into fuel oil will be recycled to the furnace for heating the reactor, maximizing resource utilization.

The cooling water adopts a circulating mode, which is pollution-free, no discharging, and recyclable.

High efficiency discharging: Adopt screw conveyor discharging device, discharge carbon black in sealed condition, no pollution and save labor and time.

Fast installation: All of the condensing parts have been installed together before delivery from the factory, saving installation time and ensuring welding quality.

Specification

Item | Contents | |

| Input-Raw Materials | Waste engine/motor oil/Lubrication oil | |

| Average out-put oil rate | 85%-90% | |

| By-products | Diesel oil, waste gas, slag | |

| Structure form | Horizontal | |

| Operating pressure | Constant pressure | |

| Heating material | Coal, charcoal, fuel gas, fuel oil | |

| Model(Diameter*Length)(mm) | Reactor size | Capacity |

| D1500*L3000 | 3 Ton/Day | |

| D2000*L5000 | 5 Ton/Day | |

| D2800*L6000 | 10 Ton/Day | |

| Material of reactor | Q245R&Q345R boiler plate | |

| Thickness of reactor | 16mm, 18mm | |

| Mode of cooling | Circulating water cooling | |

| Space needed | Length: 30m, Width :10 m at most | |

| Power consumption | Average 15 KW/h | |

FAQ

1. What is the price of one complete set of waste pyrolysis plants?

The price of the pyrolysis plant depends on the configuration, and capacity, please contact us to get the latest quotation.

2. What payment methods do you accept?

A: We can accept T/T, L/C, Western Union.

3. Does waste pyrolysis plants pollute the environment?

With a powerful de-dusting system, the smoke will be desulfurization and purified before being discharged out. SGS emission reported provided.

4. How many countries have your machines been exported to?

HUAYIN equipment has been exported to over 80 countries including Romania, Hungary, Turkey, Slovakia, Ecuador, Guatemala, Haiti, Mexico, Peru, Canada, Jordan, UAE, Lebanon, Italian, Chile, Poland, England, Thailand, Greece, Mexico, Benin, Indonesia, India, Singapore, Russia, etc.

5. How long will it take to get the machine?

The delivery time is 15 -25 working days.

|