| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Pyrolysis Oil Plant |

|---|---|

| Brand Name: | Huayin |

| Model Number: | HY-6ton |

| Certification: | CE ISO |

| Place of Origin: | Xinxiang city, Henan,China |

| MOQ: | 1 set |

| Price: | USD35000-45000 per set |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 220 sets per year |

| Delivery Time: | 15-25 work days |

| Packaging Details: | plastic flims for pyrolysis reactor , wooden boxes for small parts |

| Product name: | huayin plastic pyrolysis oil plant machine layout 6 ton/day plastics pyrolysis |

| Function: | waste tyre to oil machine |

| Rotating speed: | 0.4 turn/minute |

| Input raw material:: | waste tyres, plastic, pmma |

| Output product: | Fuel oil , Carbon black ,steel wire, syngas |

| Opeartor: | 3-4 workers |

| Heating fuel: | Wood /Coal /Gas /Oil |

| type: | batch type |

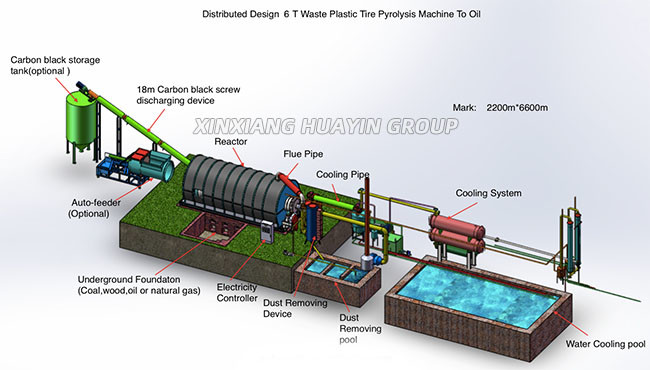

Huayin Plastic Pyrolysis Oil Plant Machine Layout 6 Ton/Day Plastics Pyrolysis

Product description

1. The waste plastic pyrolysis plant function is converting waste plastic into fuel oil, carbon black, and syngas.

2. Capacity from 1 ton-15ton capacity per batch. Support customization.

3. Fast installation design & Bulk type design &Container design

4. Environmental friendly, no black smoke and waste water discharged out.

5. Large condensing area ensures a high oil yield.

6. Low operating cost.

7. High Automation. Auto feeding systems and discharging carbon black devices make this recycling machinery much easier to operate.

8. Certification: CE, ISO, SGS, BV.

9. Material of reactor: Q345R/Q245R/310S+Boiler plate/Stainless steel, thickness 16mm/18mm.

Output product and usage

Fuel Oil (50%-75%)

1. Used as the heating material and sell it to cement factories,

glass factories, ceramic factories, electric power factories, steel

making factories, boiler factories, etc.

2. Used in heavy oil generator for electricity generation.

3. Deep process it into diesel oil with our distillation plant,

color and smell removal system, the final oil can be used in diesel

engines like trucks, tractors, etc.

Carbon Black (30%-35%)

Slag for construction.

Flammable Gas (8%-10%)

1. Recycled into the furnace to heat reactor instead of

coal/wood/oil/natural gas.

2. Storage the extra gas to restart the next batch.

Oil ratio

| Raw materials | Oil ratio |

| PP (Microwave oven food box/yogurt bottles, ect.) | 50%-75% |

| PS(fast food boxes/instant noodle boxes) | 50%-75% |

| PE(plastic film/plastic wrap) | 50%-75% |

| Plastic cable | 80% |

| ABS(engineering plastic) | 40% |

| Leftovers of paper | Wet 15-20%,Dry 60% |

| House garbage | 35%-50% |

| Plastic bags | 50% |

| Submarine cable | 75% |

| Rubber cable | 35% |

| Sole | 30% |

| Small tires | 45%-50% |

| Big tires | 35%-40% |

Specification

| Item | Content | |

| Raw materials | Waste tyre/rubber | |

| Output | 45% fuel oil, 30% carbon black, 10% steel wire, 10%-15% syngas | |

| Model | Reactor size | Capacity |

| HY1500*3000 | 1 T/batch | |

| HY2200*5500 | 5 T/batch | |

| HY2200*7500 | 7 T/batch | |

| HY2600*6600 | 8 T/batch | |

| HY2800*6000 | 9 T/batch | |

| HY2800*6600 | 10 T/batch | |

| HY2800*8000 | 15 T/batch | |

| Remarks | Support customization | |

| Reactor material and thickness | Q345R/Q245R/310S (Boiler plate/stainless steel) 16mm/18mm | |

| Land area | 300-400㎡ (L30-40m*W10m) | |

| Number of workers | 3-4 | |

| Oil density and calorific value | 0.89g/cm³&44.30KJ/KG | |

| Processing time and power | 10-24 hours. Averagely 15KW/h | |

| Certification | CE, ISO, BV, SUV, SGS Oil Report, Emission Report, 11 patents | |

Main features

1) Industrial batch type, different capacity from 1ton to 15ton per batch.

2) low consumption, high oil yield, and quality, continuous and steady operation of production.

3) Horizontal rotating reactor enables the waste material equally heated and completely pyrolyzed to achieve high production efficiency.

4) Anti-coking device, alarm, auto pressure releasing device, anti backfire device, vacuum pump to ensure operation safe and reliable.

5) Combustible Gas recycling utilization technology, the combustible gas can be used for heating, remaining heat can be fully utilized, realized self-supply for pyrolysis process, dramatically minimizing running cost.

6) Adopt 3 layers of ceramic packing dedusting device and water spray, finally, no black smoke discharged out. SGS emission report provided.

7) Support PLC system to achieve high automation production and ensure operation under safety conditions.

8) Low requirement for manpower and clean production.

Our company

Xinxiang Huayin Renewable Energy Equipment Co., Ltd is located in Xinxiang City, Henan Province, and is specialized in manufacturing waste tires/plastics to fuel oil pyrolysis machines and waste oil for diesel distillation machines since 1993. We have more than 2000 square meters of running demo plants for customers' visitation and learning. our plants have been exported to over 80 countries around the world including Romania, Hungary, Turkey, Slovakia, Ecuador, Guatemala, Haiti, Mexico, Peru, Canada, USA, Jordan, UAE, Lebanon, Kuwait, Italy, Chile, Poland, England, Thailand, Greece, Mexico, Benin, Indonesia, India, Singapore, Russia, etc.

|