| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Wire Mesh Welding Machine |

|---|---|

| Brand Name: | HWASHI |

| Model Number: | WL-SQ-150K*2 |

| Certification: | CE |

| Place of Origin: | CHINA |

| MOQ: | 1 set |

| Price: | Negotiation |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 50 sets per month |

| Delivery Time: | 30 - 45 working days after received your payment |

| Packaging Details: | Sea worthy wooden package or PVC Film for FCL |

| Product Name: | Automatic Rebar Mesh Welding Machine Wire Mesh Making Spot Welder Industrial Production Equipment Cage Wire Mesh Welded |

| Dimension(L*W*H): | According to your product |

| Weight: | According to your product |

| Core Components: | PLC, Engine, Motor |

| Warranty: | 1 Year |

| Welding Power Source: | AC / MF DC |

| Company Info. |

| GUANGDONG HWASHI TECHNOLOGY INC. |

| Verified Supplier |

| View Contact Details |

| Product List |

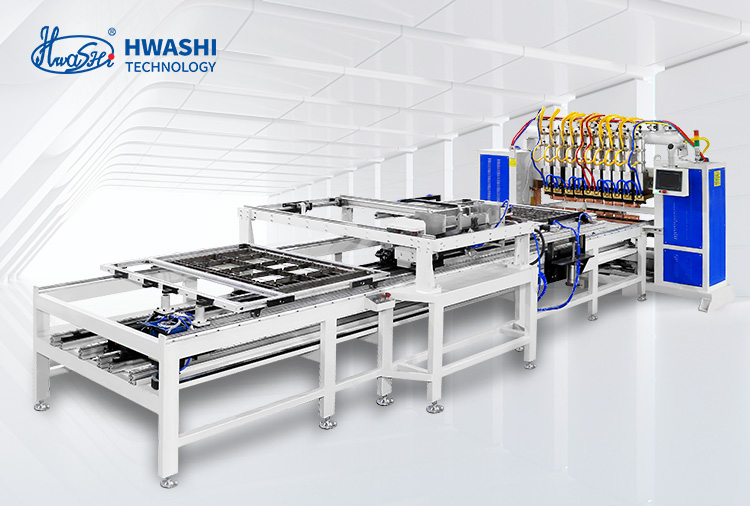

Automatic Rebar Mesh Welding Machine Wire Mesh Making Spot Welder

Industrial Production Equipment Cage Wire Mesh Welded

The wire mesh multi-head automatic welding machine introduces a

cutting-edge approach to welding processes. It stands out by

incorporating ten electrodes and a sophisticated automatic feeding

system. The system ensures seamless wire integration, with wires

dropping automatically into the fixture for a fully automated

loading process. Subsequently, the machine autonomously carries out

both feeding and welding operations.

What sets this machine apart is its one-way and double-layer

feeding device, capable of dynamic forward and backward movement to

accomplish welding tasks. The welding distance is customizable,

adding a layer of flexibility to the welding process. This

feature-rich machine is specifically tailored for batch production

scenarios, especially ideal for wire mesh requiring multiple-point

welding.

The welding methodology employed is a unique one-way double-layer

automatic stepping feeding, utilizing 10 welding heads. This

innovative approach results in an effective welding width of 1200mm

and an effective welding length of 1000mm. The machine's

composition includes a robust main machine body, welding

transformer, pneumatic drive device, upper and lower electrodes,

automatic wire filling device, an advanced electrical control

system, cooling system, and a PLC operation control system.

This state-of-the-art wire welding machine not only ensures

efficiency in batch production but also provides unparalleled

adaptability and precision in welding operations, making it a

standout solution in the industry.

|  |

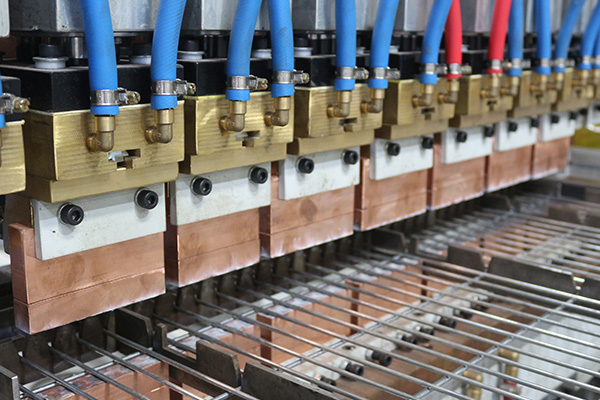

Intelligent welding control system | Welding Heads and Fixtures |

|  |

Automatic Wire Filling System | Automatic Double-layer Feeder |

Production Line Machines

|  |

Wire Flattening and Cutting Machine | High Speed Wire Straightening and Cutting Machine |

|  |

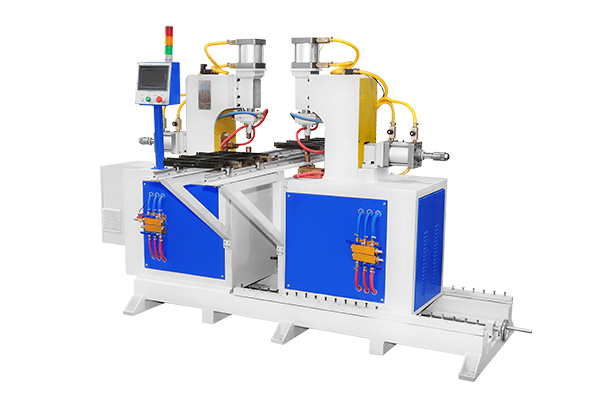

Wire Frame Bending Machine | Wire Frame Butt Welding Machine |

|  |

Wire Frame Double T-Butt Machine | Wire Edge Trimming Machine |

|  |

2D Wire Handle Bending Machine | 3D Wire Bending Machine |

|