| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Heat Resistant Castings |

|---|---|

| Brand Name: | OEM service available |

| Model Number: | OEM service available |

| Certification: | ISO9001 |

| Place of Origin: | Ningbo |

| MOQ: | 100 Units |

| Price: | Negotiation |

| Payment Terms: | T/T, L/C, D/P |

| Supply Ability: | 20000 pcs per Month |

| Delivery Time: | 4-8 weeks |

| Packaging Details: | Plywood Box/According to customer's requirement |

| Use: | Machinery Industry |

| Type: | Grate Bars |

| Material: | Heat-resistant steel |

| Product Name: | Customized Heat-Resistant Steel Castings Investment Casting For Boilier Grate Bar |

| Application: | Heavy Machinery Industry,Construction Machinery |

| Surface treatment: | Shot blasting |

| Process: | Investment Casting Process |

| Color: | Natural Color |

Customized Heat-Resistant Steel Castings Investment Casting For

Boilier Grate Bar

Description:

1. Products Information:

| Name | Customized Heat-Resistant Steel Castings Investment Casting For Boilier Grate Bar | Material | Heat-resistant steel | |

| Weight | KG | Application | Construction Machinery,Heavy Industry, | |

| Price | USD/KG | 3-3.5 | Currency | RMB USD EUR |

| Surface treatment | Shot blasting | Process | investment casting process | |

| Payment terms | 50%Mould and Clamp cost in advance, after sample approved, pay 50%balance. Pay 50%deposito of the order played, and after see the copy of B/L,pay 50%balance. | Packing | Non-fumigation Plywood case/Pallet, Also can do according to customer requirement. | |

| Terms of Trade | EXW FOB CIF | Drawing File | JPG,PDF,IGS,STP,Solidworks,CAD | |

| Delivery Time | 60days for sample making,45 days for mass production | |||

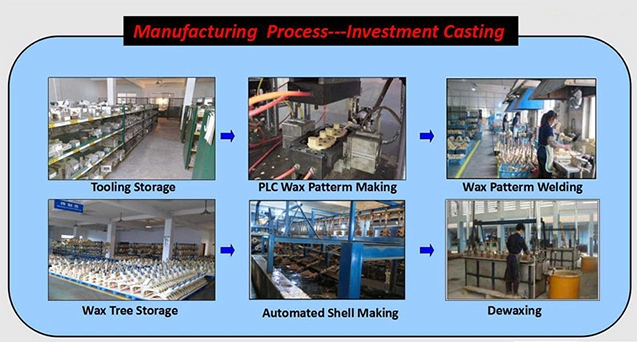

2. Manufacturing Process:

Process design⇒ Tooling making ⇒ Wax injection ⇒Wax pattern

assembly⇒ Mold preheat ⇒ Wax removal ⇒Stuccoing ⇒Dipping Casting⇒

Mold shake out ⇒Work piece cut-off ⇒ Grinding⇒ Heat

treatment⇒Machining⇒ Final inspection ⇒ Pack& transport

Advantage of Lost Wax Casting:

Lost Wax Casting-Also called Investment Casting is generally more

exppensive than it's related metal casting methods of "die casting"

or "sand casting",but can product complicated structures that

require little rework or machining.

♦ complex shapes can be cast as one part without welding

♦ products with counter-relief /inner structures can be cast

♦ machining costs are reduced to minium

♦ can be performed on almost any alloy

3. Quality Insurance

Spectrograph Spectrum Analyse Chemical Analyse

Tensile Machine&Hardness Machine Shaping Machine Simple

Hardness Test Machine

4. FAQ

a. Are you a factory or trading company?

We are have a factory and a trading department.

b. Where is your factory located?Can we have a visit?

Our factory is located in Fenghua District, Ningbo,China.You can

fly to Shanghai Airport and take the train to ningbo, Also can fly

to Ningbo Air port directly.All our clients, from home or abroad,

are warmly welcome to visit us.

c. How does your factory to regarding quality control?

Quality is priority, we always attach great importance to quality

controlling from the very beginning to the very end.We also has

gained ISO9001:2008 Authentiation.

|