| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Horizontal Machining Centers |

|---|---|

| Brand Name: | SMTCL |

| Model Number: | HMC 100Q |

| Certification: | CE ISO certification |

| Place of Origin: | CHINA |

| MOQ: | 1 |

| Payment Terms: | T/T,L/C,,Western Union |

| Supply Ability: | 50 sets per month |

| Delivery Time: | 45-60 days |

| Packaging Details: | The wooden case,Tin trunk ,Other seaworthy packing |

| CNC or Not: | CNC |

| Key word: | Heavy Duty Horizontal Machining Center |

| Max. Spindle Speed (r.p.m): | 4500 r.p.m |

| Travel (X Axis)(mm): | 1800 |

| Travel (Z Axis)(mm): | 1500 |

| Travel (Y Axis)(mm): | 1350 |

| Max. rotation diameter of workpiece: | Φ1500 |

| Company Info. |

| Shanghai HD M&E Tech Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

Product Description:

Product Features:

1,High stability structure

◆ Inverted T-shaped integrally cast bed

◆ Y-axis motor base and column are casted together

◆ Thermally symmetrical spindle

| Item | Unit | HMC 100Q |

| Work table | ||

| Worktable size | mm | 1000*1000 |

| Worktable capacity | kg | 3000 |

| Number of worktable | pcs | 1(2) |

| Working range | ||

| X axis travel | mm | 1800 |

| Y axis travel | mm | 1500 |

| Z axis travel | mm | 1350 |

| B-axis indexing | 1° ×360 | |

| Max. rotation diameter of workpiece | mm | Φ1500 |

| Distance from spindle nose to worktable center | mm | 1650 Max |

| Distance from spindle nose to worktable center | mm | 300 Min |

| Distance between s p i n d l e n o s e t o worktable surface | mm | 1600 Max |

| Distance between s p i n d l e n o s e t o worktable surface | mm | 100 Min |

| Spindle | ||

| Spindle taper (7: 24) | BT50 | |

| Maximum speed | rpm | 4500 |

| Spindle motor power (continuous/S2) | kw | 18.5/22 |

| Maximum output torque(continuous/S2) | mm | 713/871(15min) |

| Tool magazine | ||

| Tool magazine capacity | PCS | 40 |

| Max. tool length | Mm | 500 |

| Max. tool weight | kg | 25 |

| Max. tool diameter full/empty | mm | Φ125/Φ250 |

| Tool change time(T-T) | s | 5.5 |

| Feed | ||

| Maximum cutting feed speed(X/Y/Z) | Mm/min | 1-20000 |

| Rapid traverse(X/Y/Z) | M/min | 20 |

| Positioning accuracy | ||

| X/Y/Z axis | mm | 0.012 |

| B axis(1° X360) | ‘’ | 10 |

| Repetitive positioning accuracy | ||

| X/Y/Z axis | mm | 0.008 |

| B axis(1° ×360) | ‘’ | 3 |

| Overall dimension(LxWxH) | mm | 6100*5000*4600 |

| Floor space | mm | 6800*6000 |

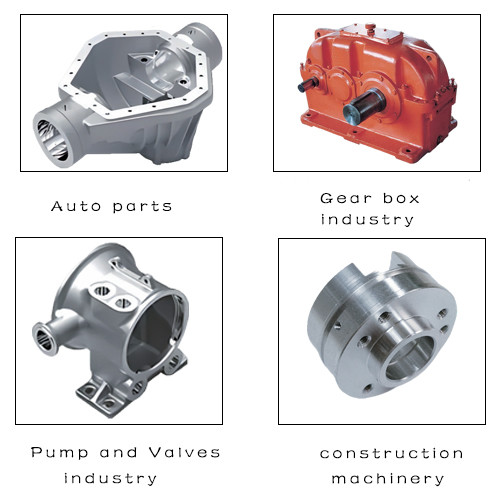

Industry application:

OUR Service:

1. Assemble and debug before delivery

FAQ:

Q1. Are you a trade company or manufacturing company?

|