| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Silicon Pressure Sensor |

|---|---|

| Certification: | CE,RoHs,ISO9001 |

| Place of Origin: | Baoji,China |

| Brand Name: | HT sensor |

| MOQ: | 1 |

| Price: | Negotiable |

| Packaging Details: | Standard Export Package |

| Delivery Time: | 5-8 work days |

| Payment Terms: | Western Union, L/C, T/T |

| Supply Ability: | 2000PCS/Month |

| Model Number: | BP157 |

| Model NO.: | BP157 |

| Power Supply: | 12-30VDC |

| Output Signal: | 4-20mA |

| Compensation Temperature: | -10~70℃ |

| Pressure Type: | Gauge Pressure, Absolute Pressure, Sealed Pressure |

| Housing Material: | 304 S.S |

| Transport Package: | Standard Export Packing with Carton |

| sensing element: | Diffused silicon pressure sensor |

| Origin: | Baoji, China |

| HS Code: | 9026201090 |

| Measuring Medium: | Liquid or Gas |

| Accuracy Grade: | 0.25%,0.5% |

| Pressure range: | 0kpa~10kpa...20MPa |

| IP Rating: | IP65 |

| Company Info. |

| Baoji Hengtong Electronics Co., LTD |

| Verified Supplier |

| View Contact Details |

| Product List |

BP157 Pressure Transmitter

Introduction of silicon pressure sensor:

BP157 silicon pressure sensor utilizes the HT series silicon pressure-resistant isolation

membrane oil-filled core as the signal measuring element. The

signal processing circuit is located inside a stainless steel

housing, converting the sensor signal into a standard output

signal. The product has undergone rigorous testing and aging

screening of components, semi-finished products,and finished

products to ensure stable and reliable performance.

Product Features:

1. Wide measuring range, stainless steel structure, diverse

pressure interface forms

2. IP65 protection rating stainless steel structure

3. Zero and full-scale adjustable

4. High precision, all stainless steel structure

Applications:

1. Pressure measurement of non-corrosive gases and liquids with

316L stainless steel

2. Applied in the marine and aviation industries

3. Used in industrial on-site processes such as petroleum,

chemical, metallurgy, power generation, and hydrology

4. Utilized in hydraulic and pneumatic control systems

Performance Parameters: | |

| Measurement Range | 0kPa ~ 10kPa…20MPa |

| Pressure Type | Gauge Pressure, Absolute Pressure, Sealed Pressure |

| Overload | ≤ 1.5 times of the rated range |

| Accuracy @ 25ºC | ±0.25% (Typ.) ±0.5% (Max.) |

| Repeatability& Hysteresis | 0.02%F.S(Typ.) 0.05%F.S(Max.) |

| Long-Term Stability | ±0.1%F.S/Year(Typ.) ±0.2%F.S/Year(Max.) |

| Zero Point Temperature Drift | ±0.02%F.S/ºC(≤100KPa) ±0.01%F.S/ºC(>100KPa) |

| Full Scale Temperature Drift | ±0.02%F.S/ºC(≤100KPa) ±0.01%F.S/ºC(>100KPa) |

| Frequency Response | 2.4Khz |

| Compensation Temperature | 0-70ºC(≤10mpa,customizable) |

| Operating Temperature | -20ºC~80ºC |

| Storage Temperature | -40ºC~120ºC |

| Vibration | 10g,55Hz ~ 2kHz |

| Housing Material | 304,316L |

| Diaphragm Material | 316L |

| Insulation Resistance | 100MΩ 100VDC |

| Explosion-proof Rating | Ex db IIC T6 Gb |

| Protection Rating | IP65 |

| O-Ring Seal | Fluoro rubber |

| Weight | ~0.05kg |

| Output Signal | Supply Voltage | Output Type |

| 4~20mA | 12~30VDC | 2/3/4 wire |

| 0~10/20mA | 3 wire | |

| 0/1~5V | ||

| 0/1~10V | ||

| 0.5~4.5V | 5VDC |

| Ordering tips: |

1. Measurement range: Determine the required pressure measurement range, i.e. the minimum and maximum pressure values to be measured. Ensure that the measurement range of the selected diffused silicon pressure transmitter meets the requirements of the application.

2. Output signal type: Determine the desired output signal type,

such as an analog signal (such as 4-20mA or 0-10V) or a digital

signal (such as RS485 or Modbus). Make sure the output signal type

of the transmitter you choose is compatible with your control

system or device.

3. Accuracy requirements: Determine the required pressure

measurement accuracy. Different applications may have different

accuracy requirements, choose the diffused silicon pressure

transmitter that suits your application needs.

4. Temperature range: Consider the temperature range of the

application environment to ensure that the selected transmitter can

work properly in this temperature range.

5. Media compatibility: Understand the properties of the medium

being measured, such as liquid or gas, and ensure that the selected

diffused silicon pressure transmitter is compatible with that

medium.

6. Mounting method: Determine the mounting method of the

transmitter, such as flange mounting, thread mounting or other

methods. Make sure the transmitter you choose matches your

installation needs.

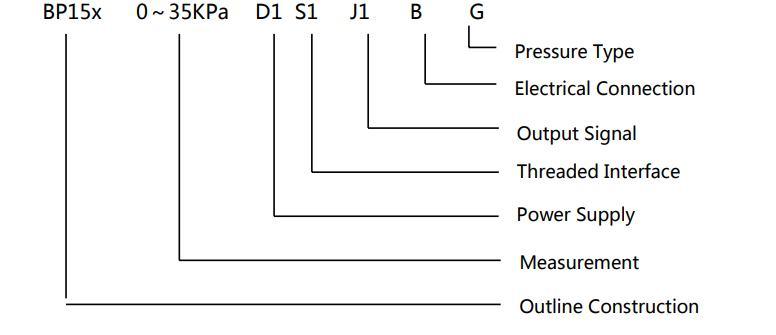

| Order Guide: | |||||||||

| BP15X | Analog Pressure Transmitter | ||||||||

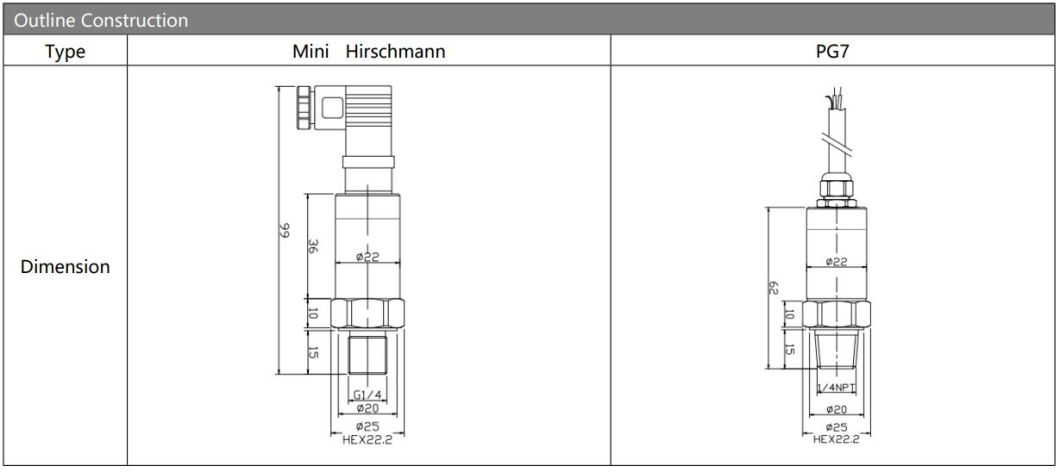

| Code | Outline Construction | ||||||||

| 5 | Packard plug | 6 | Sealed Direct Output Cable 1.5 meters | ||||||

| 7 | Mini Hirschmann Connector | 8 | Large Hirschmann Connector | ||||||

| Measurement Range | 0kPa ~ 10kPa…5MPa | ||||||||

| (0-X)Kpa or MPa | X: Indicates the Actual Measuring Range | ||||||||

| Code | Power Supply | ||||||||

| D1 | 24VDC | ||||||||

| D2 | 5VDC | ||||||||

| D3 | Other | ||||||||

| Code | Output Signal | ||||||||

| S1 | 4~20mADC | S5 | 0~20mADC | ||||||

| S2 | 1~5VDC | S6 | 0~10VDC | ||||||

| S3 | 0~5VDC | S7 | 0.5~4.5VDC | ||||||

| S4 | 0~10mADC | ||||||||

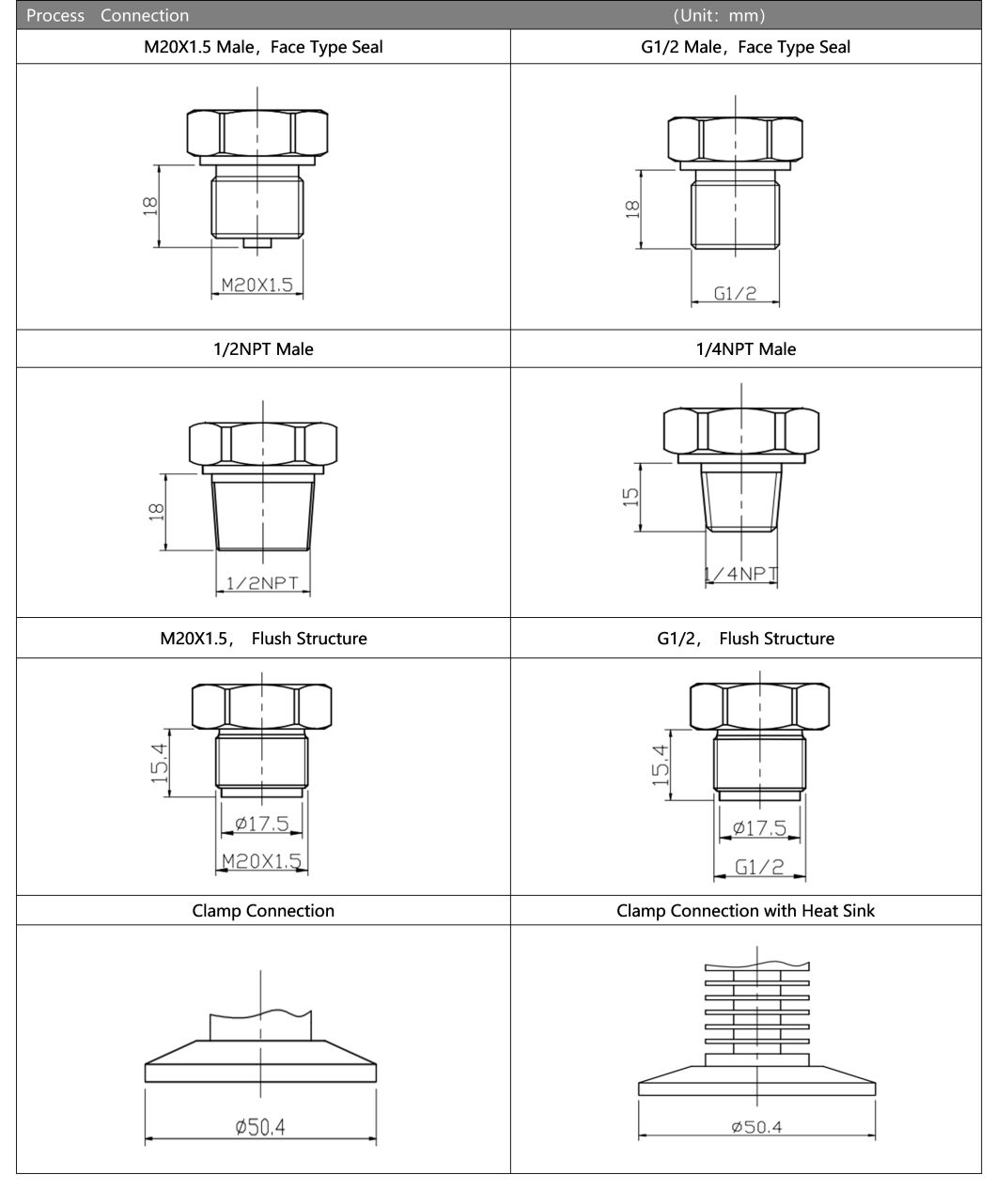

| Code | Pressure Connection | ||||||||

| J1 | M20×1.5 | ||||||||

| J2 | G1/2 | ||||||||

| J3 | G1/4 | ||||||||

| J4 | 7/16-20UNF | ||||||||

| J5 | Others(¢50.4 Flange) | ||||||||

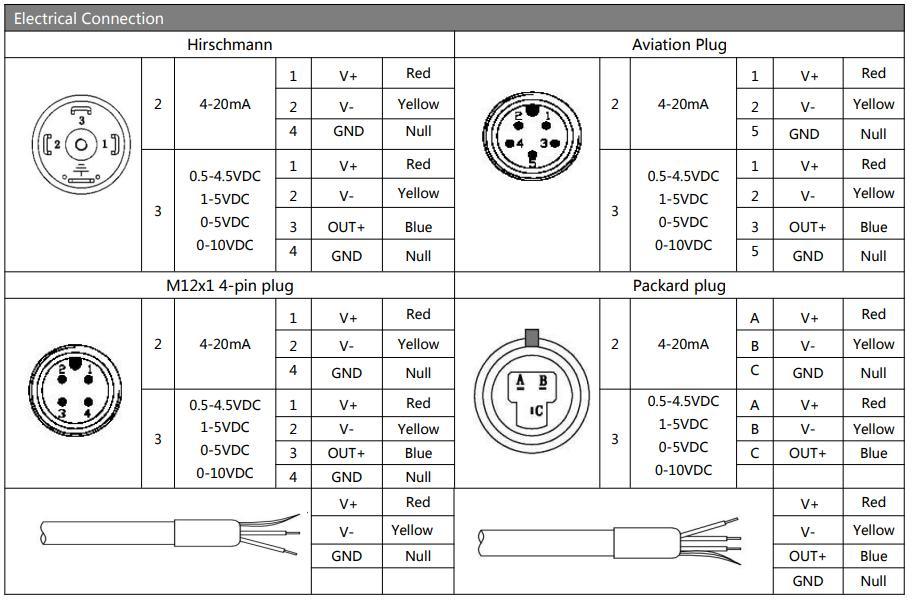

| Code | Electrical Connection | ||||||||

| B1 | Hirschmann | ||||||||

| B2 | PG7 | ||||||||

| B3 | Cable Sealed Outlet 1.5 meters | ||||||||

| B4 | Other | ||||||||

| Code | Pressure Type | ||||||||

| G | Gauge Pressure | ||||||||

| A | Absolute Pressure | ||||||||

| S | Sealed Reference Pressure | ||||||||

|

|